A team of researchers have designed a continuous fiber extruder for desktop 3D printers which allows the embedding of long fiber into the hydrogel to enhance the mechanical strength of soft robots

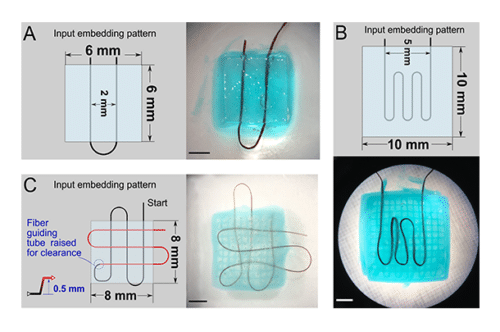

Soft robots developed with a 3D printing process using hydrogels as ink are very delicate and not suitable for robotic applications. To overcome this hurdle, Wenhuan Sun, a Ph.D. student in mechanical engineering opens in a new window, co-advised by Victoria Webster-Wood and Adam Feinberg designed a continuous fiber extruder, this device reinforces the hydrogels to improve their mechanical strength, this makes them tough and not to break easily and also to retain their shape when loaded. Embedding fibers into hydrogels during the 3D printing process strengthens their mechanical properties so they are not delicate and fragile.

Initially, hydrogels, made of synthetic or natural materials from polyester to sodium alginate, are used as ink for 3D printing. After printing, it forms a multidimensional structure that is soft and delicate. When the hydrogels are placed in the right environment, the monomers in the liquid crosslink to form polymers, that provide shape to the hydrogel. Further, to provide mechanical strength to these hydrogel-based soft robots, they are embedded with fiber using a continuous fiber extruder. This process protects their structural integrity and makes them ready for a greater variety of tasks and harsh environments. Their distinctiveness allows them to be used for biomedical applications such as drug delivery and tissue engineering

“We’re interested in how we can use biodegradable materials in robots,” says Webster-Wood, an assistant professor of mechanical engineering who founded the Biohybrid and Organic Robotics GroupOpens in a new window. “These plant-based hydrogels are a really interesting direction because we can farm the materials for the robots and make them renewable.”

They created an open source, commercially available fiber extruder to allow others to apply it for further research with hydrogels. It’s cheap and also compatible with many at-home 3D printing devices and has been tested successfully in hydrogels embedded with both synthetic and natural fibers, including silk and collagen.

Click here for the Published Research Paper