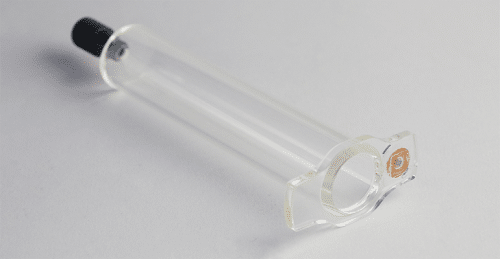

NP Plastibell has revealed a truly innovative syringe with near-field communication (NFC) tag embedded in it. The NFC tag used in this syringe is from STMicroelectronics which is directly over-moulded into the syringe, the STM tag can store information and enables doctors, patients and staff to access important medicine-related information. The syringe is safe for medical use and has been sterilized at a temperature above 130°C by autoclave without damaging the electronics.

According to the company, the ultra-compact NFC tag is molded directly into the body of the syringe. While the syringe is filled with medicine, the pre-filled syringe can store important manufacturing and product-related data such as date and lot of manufacturing, it can also store data such as dosage recommendations, and find any other important information or warnings.

“NFC tags can store product-specific information in web links or even in a dedicated app. In this connected syringe, the tag helps medical staff get accurate information quickly on their mobile phone or using an NFC reader to find out the correct dosage, special instructions, expiration dates, storage conditions, or any other important data. Patients can also easily set up reminders by scanning the tag with their mobile,” explains Yvon Gourdou, EMEA Application and Marketing Director, Microcontrollers and Digital ICs Group, STMicroelectronics.

The company claims that the development of the product was quite challenging and STM played a crucial role in overcoming some of the challenges. Apart from embedding the NFC tag into the product, the other challenge was to ensure that the medicine doesn’t damage the tag. The product has been made in such a way that it can be sterilized syringe at temperatures above 130°C by autoclave without damaging the electronics. The company is planning to further develop connected medical devices based on ST’s ST25TV NFC tag IC.

“Once this technology is on the market, we can extend it to other medical products and so bring similar connected value to equipment such as surgical devices, implant packaging, pharmaceutical packaging, and diagnostic devices,” explains Matthieu Besse, R&D Manager at NP Plastibell.