With the acceptance of computers and modular devices, virtual instrumentation has undoubtedly been universally embraced in test and measurement areas. But there are more changes happening in this field. Let us have a look at some of them very briefly

Abhishek A. Mutha

Scientists, academia and especially engineering professionals seem to be driving virtual instrumentation. A major benefit of virtual instrumentation is accelerated project development (which in turn drives better control and design) and cost-effective solutions. However, virtual versus traditional instrumentation is a very subjective issue.

While virtual instruments provide flexibility through user-defined devices, traditional box instruments have fixed, vendor-defined functionality but are powerful. Virtual systems are modular and fast whereas box instruments are traditionally easy to use with all the knobs, buttons and screen displays that are now also available with touch-screen functionality.

Virtual instrumentation in box

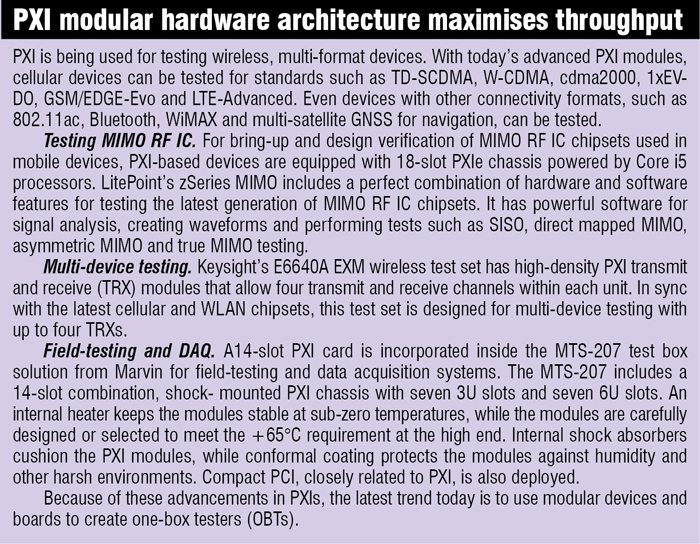

Thinking out of the box is regarded as a positive trait but sometimes thinking inside the box could also set a trend. Test and measurement companies are using PXI (PXI stands for PCI eXtensions for Instrumentation) modules to create one-box testers for various wireless communication applications such as base station manufacturing test, power amp test, RF IC test and MIMO test. With advanced processors, easy-to-use software and improvements in technology, PXIs are becoming even more powerful and a better alternative.

A PXI system is typically used by manufacturers of cell phones and other cellular devices. It not only offers the manufacturers faster time-to-market by incorporating controllers, chassis and existing PXI modules but it can also be upgraded easily by appending new instruments to it. Although every vendor is selling PXI modules separately, companies are pushing bundled solutions as they feel these solutions best demonstrate and represent customer and vendor advantages of using PXI-inside approach.

PXI is an open, PC-based platform with test, measurement and control capabilities in a low-cost, modular package. You can mix and match different open standard PXI modules to incorporate the exact control I/O and measurement required in each system. Triggering features and integrated timing in PXI backplane provide precise inter-module synchronisation. Vendors can easily pre-configure systems to match a customer’s requirements and applications.

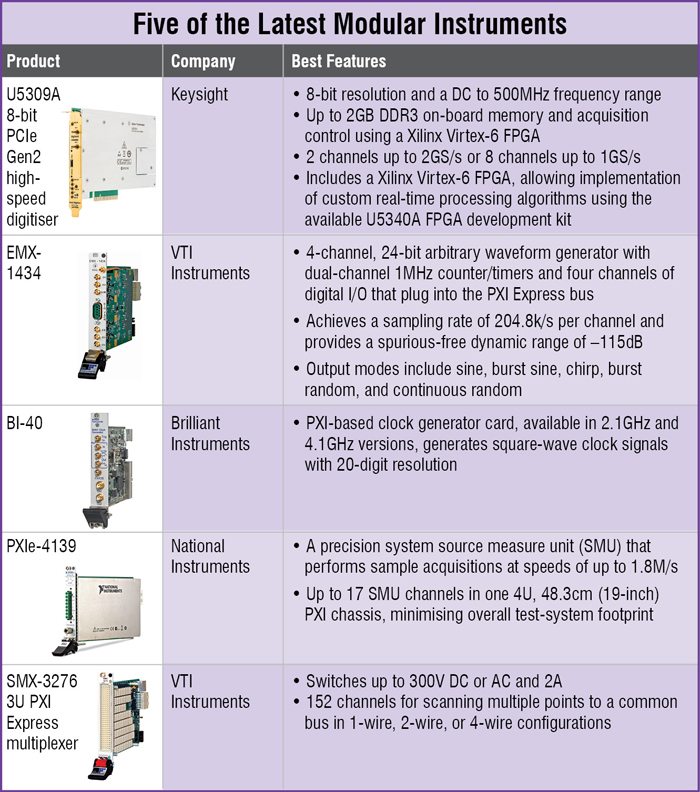

PXI Express multiplexers are capable of switching up to 300V DC or AC voltages and 2A current. They furnish around 152 channels for scanning multiple points to a common bus in 1-wire, 2-wire, or 4-wire configurations. The SMX-3276 3U PXI Express multiplexer from VTI Instruments gives ATE system designers the ability to switch input signals with up to 34MHz bandwidth, while reducing crosstalk levels to as low as -70dB at 100kHz.

Another advantage that PXI has is the power of integration, which allows you to easily integrate another vendor’s product into your instrument.

On the downside, especially in case of high-volume applications, PXI adds significant cost as compared to a custom-integrated solution. Also, industry experts believe that there is a lack of ruggedised PXI products for extreme environments. Commercial PXI products are typically not designed for harsh environments. Therefore, depending on the product, some kind of tweaking may be needed to modify the instrument, which could also add to cost. Some of these single-box PXI test devices look like traditional test-bench instruments.

Many instruments in one

“Today, a typical workspace of a typical design/test engineer includes an oscilloscope, a digital multimeter, a power supply and a function generator. Each instrument includes its own separate display and knobs/buttons,” says Chinmay Anand Misra, certified LabVIEW developer, technical marketing engineer, National Instruments. He adds, “Because of these multiple redundant components, the instruments take up a lot of space, increase the cost of the set-up, and are in general cumbersome to work with if multiple of them are used at a time.”

An upcoming trend, to solve the above issue, is integration of diverse instrumentation equipment, such as oscilloscope, function generator, multimeter and power supply in a single box using modular packages and providing a software for test and measurement. A user can interact with the instrument via software applications that run on PCs or iPads. This opens up new possibilities for design engineers, entrepreneurs and even academicians.

National Instruments recently announced its VirtualBench that has a lot of functionality within it. It incorporates a mixed-signal oscilloscope (2ch analogue, 32ch digital) having 100MHz bandwidth, 1G/s sampling rate and 8-bit), function generator (20MHz sine, 14-bit, 125 MS/s), digital multimeter (five-and-a-half digit, 300V and 10A max), DC power supply (+6V @ 1A, +25V @ 0.5A, -25V @ 0.5A) and digital I/O (8ch LVTTL). Though it aims at simplifying circuit debugging and validation with a diverse functionality, it costs US $2000.

FPGAs for more power

Another interesting development is the concept of software-defined ratio (SDR). Although SDR has been around for many years, it has become really viable only in the recent years. The main idea is to configure an FPGA within a PXI instrument exactly as per required test specifications. A software-defined virtual instrument makes available raw data from the hardware to the end users so they can define their own measurements and user interfaces. A combination of general-purpose, modular hardware and software-defined virtual instrumentation enables an end user to exploit the full flexibility and performance of the measurement software.

FPGAs allow implementation of custom real-time processing algorithms. Consider Keysight’s PCIe Digitizer U5309A. At the heart of the U5309A is a data processing unit (DPU) based on Xilinx Virtex-6 FPGA. Responsible for supervising the module functionality, data flow and real-time signal processing, this powerful FPGA allows data storage and reduction to be carried out at the digitiser level, speeding-up analysis and minimising transfer volumes.

An end user of an instrument with an ‘open’ FPGA can fully personalise the functionality of the instrument by adding application-specific measurements, custom triggering or the capability to use new digital protocols onto the system, to name a few. Essentially, the user can tweak firmware of the device to meet requirements—not just defining in software how the data should be used but also adding new functionalities that the instrument can perform. Using this approach boosts test speed.

The FPGA in Keysight’s Digitizer is primarily intended to open the design of the FPGA to specific user requirements by providing a development framework that interfaces to the underlying hardware. It mainly looks to achieve multi GS/s real-time processing on a full digitiser framework by leveraging full density and speed of the FPGA. It also boosts the time-to-market with turn-key, easy-to-use development flow and debug.

Cloud-connected and voice-controlled instruments

Engineers have been transferring data between their devices using USB drives or a network, but now it possible to do so with cloud technologies. Besides storing files in the cloud, some services host full applications in the cloud.

“Instrumentation that incorporates network and cloud connectivity could provide these same benefits to engineers. Both the data and user interface could be accessed by multiple engineers from anywhere in the world,” says Misra. He adds, “When debugging an issue with a colleague who is off site, rather than only sharing a static screenshot, engineers could interact with the instrument in real time to better understand the issue. Cloud technologies could greatly improve an engineering team’s efficiency and productivity.”

Also, context-aware computing is beginning to emerge and could fundamentally change how we interact with devices. This technology uses situational and environmental information to anticipate users’ needs and deliver situation-aware content, features and experiences. A popular example of this is Siri, a feature found in recent Apple iOS devices.

Similar intelligence when combined with instrumentation could be game-changing. A common challenge that engineers face is attempting to make configuration changes to an instrument at the same time that their hands are tied up with probes. Misra says, “Voice control could not only provide hands-free interaction but also easier interaction with features. In addition, predictive intelligence could be used to highlight relevant or interesting data. An oscilloscope could automatically zoom and configure based on an interesting part of a signal, or it could add relevant measurements based on signal shape.” “An instrument that leverages mobile devices could integrate and take advantage of context-aware computing as the technology is developed.”

The author is a senior technical correspondent at EFY