Researchers at Nagoya University have unveiled an ultra-thin loop heat pipe that promises to solve overheating in smartphones and tablets — allowing for slimmer, faster, and more reliable devices without compromising performance.

Scientists at Nagoya University in Japan have developed an ultra-thin loop heat pipe (UTLHP) that could transform the way smartphones and tablets manage heat. This innovative cooling system offers a major leap forward in keeping high-performance electronics cool without increasing device thickness — a breakthrough that could lead to thinner, more powerful mobile devices.

The research, published in Applied Thermal Engineering, tackles one of the biggest design challenges in modern electronics: managing the heat produced by powerful components packed into increasingly slim devices. Traditional cooling systems often struggle to handle the demands of advanced applications like gaming and video processing, which can cause overheating and slow performance.

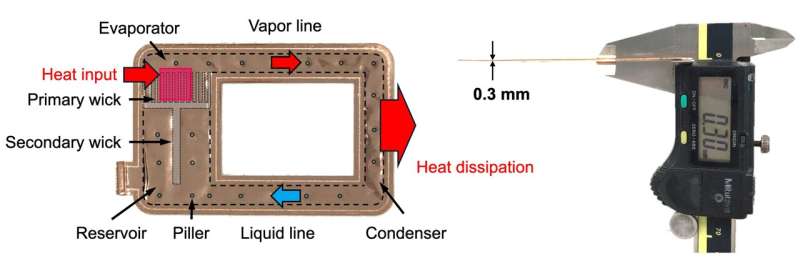

The team’s UTLHP offers a solution by combining thinness, efficiency, and stability. Unlike standard heat pipes, which transfer heat in a straight path, loop heat pipes circulate liquid in a continuous loop. This system uses a porous “wick” structure — created from sintered copper powder — that enables capillary action to drive the liquid without external power. Water inside the pipe absorbs heat, evaporates, moves to a cooler section, and condenses back to liquid, repeating the cycle.

The Nagoya University researchers designed the UTLHP by laser-welding thin copper sheets embedded with the sintered copper wick. The result is a durable, ultra-thin cooling system just 0.3 mm thick — slim enough for modern smartphones and tablets. Tests showed that the UTLHP could stably transport up to 10 watts of heat, whether the device was held vertically or horizontally. The device’s heat transfer performance is remarkable: about 45 times higher than copper and 10 times better than graphite sheets, both of which are already known for their excellent thermal conductivity.

Beyond smartphones and tablets, the UTLHP also fits the international size standard for contactless smart cards, opening the door for future applications in next-generation cards and compact electronics.

According to Professor Hosei Nagano, the technology could extend battery life and allow thinner device designs without sacrificing performance. Master’s student Jun Sasaki, first author of the study, emphasized the growing need for advanced heat management as devices become smaller and more powerful, calling efficient cooling “an urgent issue” for modern electronics.