Carnegie Mellon University researchers have developed a unique type of microelectrode array from the brain-computer interface (BCI) platforms for customized treatments of disease

The two most popular kind of BCI devices is the Utah array, developed at the University of Utah (silicone-based array), and the Michigan array (printed on flat, delicate silicone chips). But both the arrays could only record on a two-dimensional plane and were not customizable to meet the needs of each patient and application. Hence, researchers have developed CMU Array- a new type of microelectrode array for brain-computer interface platforms.

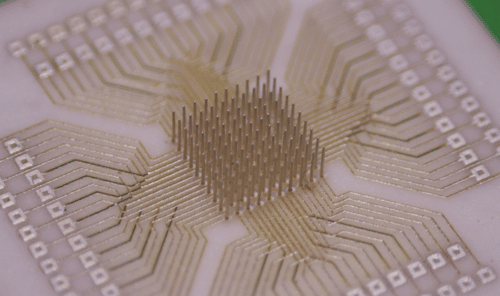

CMU Array is customizable and capable to transform how doctors can treat neurological disorders. The team implemented the newest microfabrication technique, Aerosol Jet 3D printing, to fabricate arrays that solved the major design barriers of other brain-computer interface (BCI) arrays. CMU Array is the densest BCI, about one order of magnitude denser than Utah Array BCIs.

“Aerosol Jet 3D printing offered three major advantages,” explained Panat, associate professor of mechanical engineering. “Users can customize their MEAs to fit particular needs; the MEAs can work in three dimensions in the brain, and the density of the MEA is increased and therefore more robust.”

A-based BCIs connect neurons in the brain with external electronics to monitor or stimulate brain activity. They are often used in applications like neuroprosthetic devices, artificial limbs, and visual implants to transport information from the brain to extremities that have lost functionality. BCIs also have potential applications in treating various neurological diseases. However, conventional devices have limitations such as density issues of microelectrodes. Modern MEA manufacturing techniques have made tremendous advances regarding the density of these microelectrode arrays. Adding the third dimension significantly increases the sampling ability of the arrays. In addition, custom-made MEAs for each specific application allow for more accurate and higher-fidelity readings.

“Within a matter of days, we can now produce a precision medicine device tailored to a patient or experimenter’s needs,” says Yttri, co-senior author of the study. Technologies like visual cortex stimulation and artificial limb control are used successfully by the public, and being able to personalize the control system in the brain could pave the way for enormous advances in the field.

Panat predicts that it may take five years to see human testing, and even longer to see commercial use. The team is excited to get this successful process out to other researchers in the field to begin testing a wide variety of applications.

Click here for the Published Research Paper