Researchers have developed a new method for 3D-printing microrobots with multiple component modules inside the same microfluidic chip.

Present medical technology has made once impossible surgeries possible. Yet we stand far away from a future where microbots perform instantaneous surgeries coursing through a patient’s body. Microsurgery has been considered a topic of curiosity for a long time.

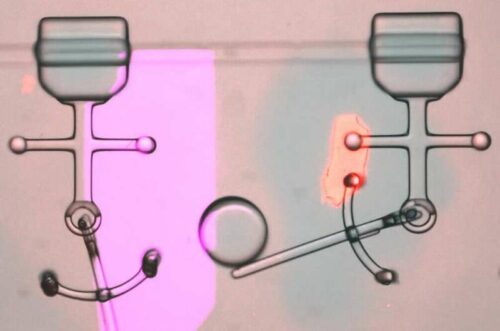

Researchers at the Department of Mechanical Engineering at Osaka University have brought us one step closer to the idea of microsurgery. They have developed a method for manufacturing complex microrobots driven by chemical energy using in situ integration. By 3D-printing and assembling the mechanical structures and actuators of microrobots inside a microfluidic chip, the resulting microrobots were able to perform desired functions, like moving or grasping. This work may help realize the vision of microsurgery performed by autonomous robots.

“Recently, microrobot development has been transitioning from hard and rigid structures to soft and flexible architectures” first author Yingzhe Wang says. The stepwise process was simplified and streamlined compared with previous methods by assembling the different modules in place.

Nanotech production methods are developed yet, it remains a challenge to manipulate and assemble these constituent parts into functional complex robots, especially when trying to produce them at a mass scale. As a result, the assembly, integration and reconfiguration of tiny mechanical components, and especially movable actuators driven by chemical energy, remains a difficult and time-consuming process. Soft microrobot structures are produced by shining laser light to harden a photo-inducible biocompatible hydrogel, poly (ethylene glycol) diacrylate.

“Our in situ integration of actuators and mechanical structures improved the flexibility and efficiency of microrobot fabrication, which may help realize the currently difficult problem of mass production,” senior author Keisuke Morishima says. In addition to health care applications, these robots can also help in the fabrication of yet more complex robots, by acting as microfluidic valve or manipulators.