Researchers have developed a way to 3D print hydrogel based electronic devices to facilitate increasing complexity of manufacturing.

Hydrogels have emerged as they are promising material platforms for both biomedical and environmental applications, as they can survive in bodily fluids or in wet natural environments without dissipating. Hydrogels are three-dimensional (3D) polymer networks that do not dissolve in water but retain large amounts of liquids. Researchers have been developing various electronic devices based on soft hydrogels, including environmental and biomedical sensors, drug delivery devices, and artificial tissue.

A research team led by Dr. Nanjia Zhou at Westlake University and Westlake Institute of Advanced Studies in China have recently introduced a new strategy to enable the 3D printing of soft hydrogel electronics. They aimed to develop an efficient strategy to fabricate increasingly complex and biomedically useful hydrogel-based electronics. Their proposed approach is based on 3D printing technology, specifically utilizing a hydrogel-based supporting matrix and a stretchable silver-hydrogel ink.

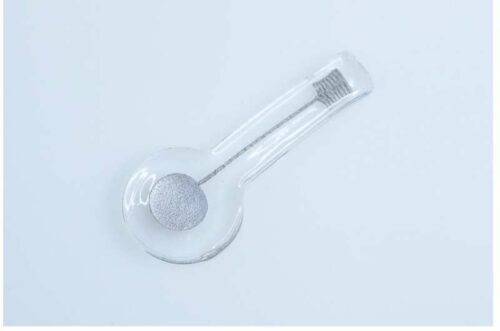

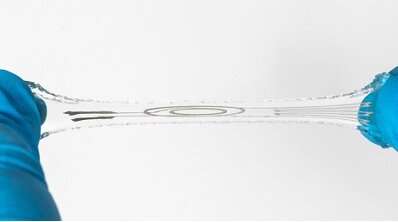

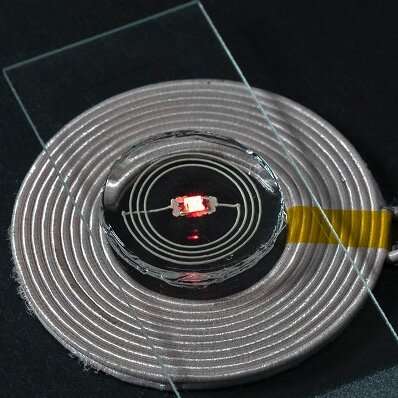

The 3d printing method involves the freeform printing of a conductive hydrogel ink into a hydrogel supporting matrix, and the subsequent curing of the two parts to form a soft and stretchable electronic device. These are based on the suitable rheological properties of the matrix and the ink, as well as the orthogonal curing mechanism of alginate and polyacrylamide, which are the main components of the hydrogel.

Researchers found that combining a conductive filler (i.e., silver flakes) with granular gel particles led to the formation of a segregated structure in the conductive 3D printing ink. It was observed that the ink exhibited a remarkable electrical conductivity of over 1,400 S/cm.

Researchers tested their strategy by creating a series of hydrogel-based electronics, including strain sensors, inductors and biological electrodes. The resulting devices were found to perform exceptionally well, suggesting that this approach could be used to create a range of new hydrogel-based technologies. Researchers are currently working on improving their strategy to further facilitate its real-world and large-scale implementation.

Reference : Yue Hui et al, Three-dimensional printing of soft hydrogel electronics, Nature Electronics (2022). DOI: 10.1038/s41928-022-00887-8

This is great.