These small generators may pave the path for self-charging smart technology.

According to a study, the development of tiny mechanical devices powered by movement could bring self-charging smartwatches and health monitors one step closer. Researchers believe the new mechanisms, which are twice as powerful as similar existing devices, could provide an energy-efficient and long-lasting alternative to batteries used in wearable technology.

PhD students at the University of Edinburgh have devised a method for creating adaptable materials that generate electricity by capturing the energy generated by human movement. The technology produces so-called piezoelectric materials faster and more efficiently than prior methods, perhaps making production more scalable. The researchers came up with this novel method by modifying the chemistry utilised in the creation of ultrafine fibres of PVDF, a flexible material that generates electricity when pressure is applied to it.

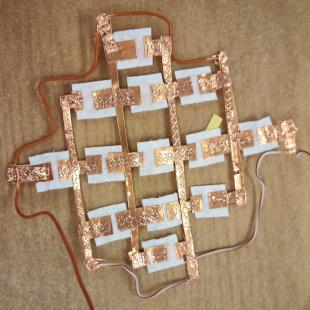

The researchers can produce 3D sponge-like materials from the fibres by employing a high-voltage power supply. The fibres are then chopped into 1 sq cm pieces, connected with electrodes and wires, and encased in silicon. The devices can produce 40 microwatts of electricity per square centimetre, according to tests, which is twice as much as the most powerful sort of piezoelectric generator now available.

According to the researchers, further development of the structures could assist to extend the life of – or perhaps replace – traditional batteries in wearable technologies, reducing electronic waste and energy consumption. The materials might also be woven into goods like motion-sensing garments and t-shirts that track respiration and heart rate in the next generation of smart textiles.

School of Engineering PhD student Francisco Diaz Sanchez, who led the research, said, “With ever-growing interest in the development of electronic wearable devices and implants, the generation of electronic waste and the limitations associated with battery capacity remain some of the key challenges to overcome. The materials we have developed bring us one step closer to the sustainable development of wearable electronics”.