No one has yet developed functional processors that can be mass-produced in billions for less than a penny each… But if they’re made with plastics, this might actually be possible!

The issue is that even the most basic industry-standard microcontrollers are too sophisticated to mass-produce on plastic. A research team from the he University of Illinois reveals a simple yet fully working plastic processor that may be built for pennies. The team created 4-bit and 8-bit processors with the goal of reducing the size and increasing the percentage of working integrated circuits produced. According to team leader Rakesh Kumar, 81% of the 4-bit version operated, which is a good enough yield to break the one-penny barrier.

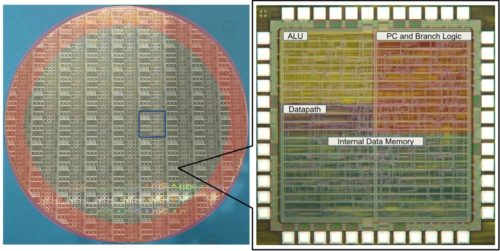

The processors his team created were produced with indium gallium zinc oxide (IGZO), a flexible thin-film semiconductor that can be put on plastic and still working even when twisted around a millimetre radius. While a dependable production method is essential, it was the design that made all the difference. Instead of adapting an existing microcontroller architecture to plastic, Kumar’s team created Flexicore from the ground up.

The researchers made the processor even simpler by constructing it to execute an instruction in a single clock cycle rather than the multistep pipelines used by today’s CPUs. Then they created logic that reuses parts to implement certain commands, lowering the gate count even more.

“In general, we were able to simplify the design of FlexiCores by tailoring them to the needs of flexible applications, which tend to be computationally simple,” says Nathaniel Bleier, Kumar’s student. All of this resulted in a 5.6-square-millimeter 4-bit FlexiCore with just 2,104 semiconductor devices (about the same amount of transistors as an Intel 4004 from 1971), compared to 56,340 for PlasticARM. “It’s an order of magnitude less than the tiniest silicon microcontrollers in terms of gate count,” he says.