Copper and aluminum can bring photovoltaic production closer to the circular economy, improving environmental and social standards.

The rising price and low availability of raw materials are leading to higher costs in producing photovoltaic modules. Researchers at Fraunhofer Institute for Solar Energy Systems ISE have developed which replaces silver with copper for the electroplating process used in manufacturing of solar cells.

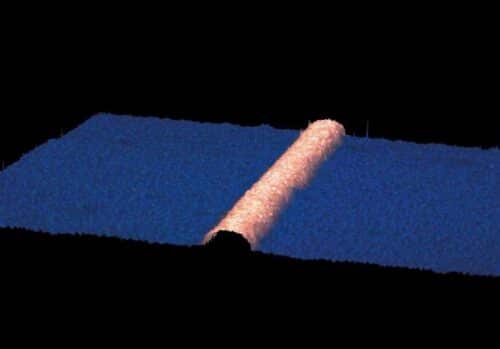

The areas with electrically conductive areas do not require complete electroplating with copper and hence first need to be masked. These areas are covered using an electrically insulating effect which prevents it from being electroplated. The copper layer will only build up in the areas not coated with the insulation.

Another significant advancement made here is that expensive polymer-based lacquers or laminated foils have been replaced with aluminum. Switching the materials twice, from silver to copper and from polymer to aluminum, also brings twice the benefit: Producing solar cells is not only more sustainable, but also significantly cheaper.

“We developed a special electroplating process that makes it possible to use copper instead of silver for the busbars,” explains Dr. Markus Glatthaar, an expert in metallization and structuring. Due to the copper line’s’ extremely small width of only 19 μm (micrometers), the light-absorbing silicon layer experiences less shading than with the silver lines. This and the high conductivity of electroplated copper improve the electricity yield.

The second technological achievement made by the Fraunhofer team is using aluminum as a masking layer. But a problem here is that the electrically conductive nature of aluminum, which renders it at first glance unsuitable to use as a mask. Researchers took advantage of the fact that aluminum can form an insulating oxide layer on its surface. “We were able to adapt the process parameters and develop a special type of electrolyte which ensures that the aluminum’s extremely thin, native oxide layer can reliably fulfill its insulating function. This was an important milestone for the success of our research project,” Dr. Glatthaar is pleased to report.

Copper and aluminum both being recyclable materials can bring photovoltaic production much closer to the circular economy, improving environmental and social standards in the process. “Given that we have sufficient supplies of copper in Germany, the supply chains are much shorter and the price is less dependent on international raw material markets or foreign suppliers,” adds Dr. Glatthaar.