The development opens door to easy fabrication of display screens in a wide range of electronic devices, both big and small

Organic light-emitting diode displays or OLED displays are quite popular for displaying high-quality media content owing to their thin dimensions and are lightweight. But they are quite expensive to purchase.

So, researchers from the University of Minnesota created a fully 3D printed flexible OLED display, which can be built at home by anyone using 3D printers, thus saving costs. With some amazing advancements made over the period and the 3D printing hardware industry set to witness a US$ 9.9 billion growth in the future, the news is exciting as it allows one to build monitors for both large and small electronic devices.

“OLED displays are usually produced in big, expensive, ultra-clean fabrication facilities,” said Michael McAlpine, professor in the Department of Mechanical Engineering at the University of Minnesota. “We wanted to see if we could basically condense all of that down and print an OLED display on our table-top 3D printer, which was custom built and costs about the same as a Tesla Model S.”

Overcoming the previous attempt at building 3D printed OLED displays where the research team struggled with keeping the light-emitting layers uniform, this time two different printing modes were employed for ensuring better light uniformity and pixels in the six device layers.

While the electrodes, interconnects, insulation and encapsulation were all extrusion printed, the active layers were instead spray printed using the same 3D printer at room temperature.

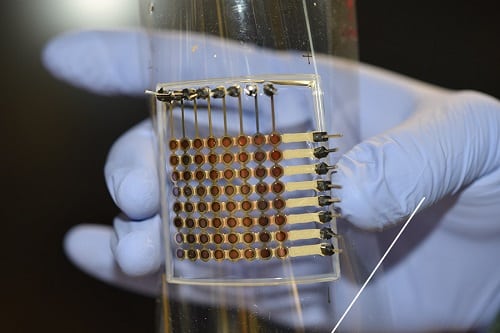

The result: a display prototype of about 1.5 inches on each side having 64 pixels.

Stating the importance of this OLED display for printed electronics, Ruitao Su, PhD graduate in mechanical engineering from the University of Minnesota and current postdoctoral researcher at MIT said, “The device exhibited a relatively stable emission over the 2,000 bending cycles, suggesting that fully 3D printed OLEDs can potentially be used for important applications in soft electronics and wearable devices.”

With this success, the researchers now plan to 3D print higher-resolution OLED displays having improved brightness.

“The nice part about our research is that the manufacturing is all built-in, so we’re not talking 20 years out with some ‘pie in the sky’ vision,” said Michael McAlpine. “This is something that we actually manufactured in the lab, and it is not hard to imagine that you could translate this to printing all kinds of displays ourselves at home or on the go within just a few years, on a small portable printer.”