Robust SEG exhibits a bandgap of 0.6 eV and demonstrates room temperature mobilities exceeding 5,000 cm² V⁻¹ s⁻¹.

Researchers at the Georgia Institute of Technology have created the world’s first functional semiconductor made from graphene, Semiconducting Epigraphene (SEG). It is robust and can handle very large currents without significant heating, addressing a common limitation in many electronic devices where excessive heat can lead to material degradation or device failure. SEG is compatible with conventional microelectronics processing methods.

The development of SEG represents a major breakthrough in the field of graphene nanoelectronics. Graphene has traditionally been limited in semiconductor applications due to its lack of an intrinsic bandgap. Efforts to modify graphene’s bandgap, either through quantum confinement or chemical functionalization, have been unsuccessful in producing a viable semiconducting form of graphene.

The recent demonstration of SEG on single-crystal silicon carbide (SiC) substrates marks a turning point. SEG exhibits a bandgap of 0.6 eV and demonstrates room temperature mobilities exceeding 5,000 cm² V⁻¹ s⁻¹. This mobility is notably 10 times larger than that of silicon and 20 times larger than other two-dimensional semiconductors, making it a highly promising material for nanoelectronics.

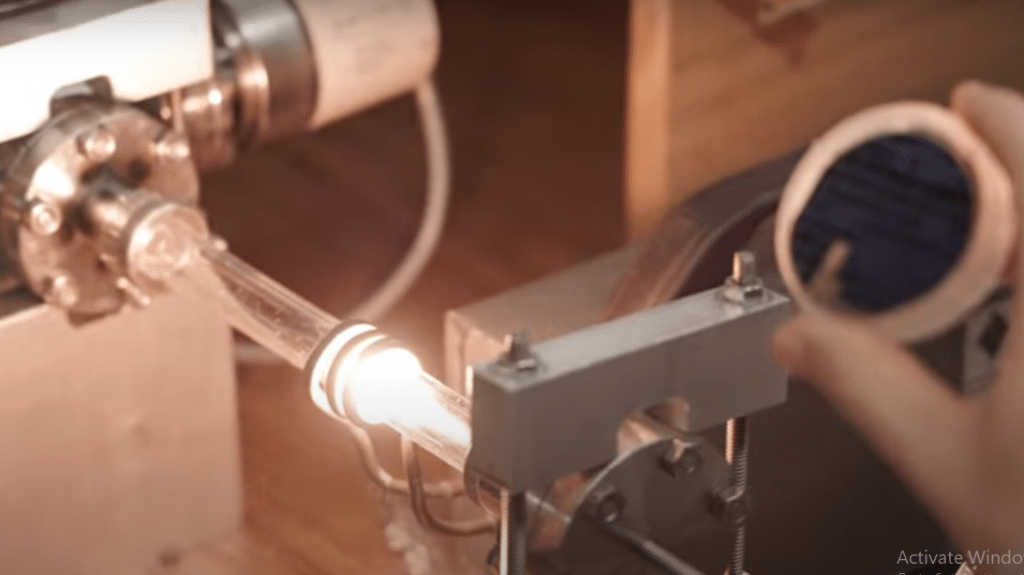

The process to create SEG involves the evaporation of silicon from silicon carbide crystal surfaces. When this occurs, the carbon-rich surface crystallises, forming graphene multilayers. The first graphitic layer that forms on the silicon-terminated face of SiC is an insulating epigraphene layer, partially covalently bonded to the SiC surface. Previous spectroscopic measurements of this buffer layer showed semiconducting characteristics, but the mobilities were limited due to disorder in the layer.

The key innovation here is the development of a quasi-equilibrium annealing method that produces well-ordered SEG on macroscopically atomically flat terraces. This process aligns the SEG lattice with the SiC substrate, resulting in a material that is chemically, mechanically, and thermally robust. SEG can be patterned and seamlessly connected to semi metallic epigraphene using conventional semiconductor fabrication techniques, which is crucial for practical applications.

The emergence of SEG opens up new possibilities for graphene in nanoelectronics. Its high mobility, coupled with its robust characteristics, makes it a suitable candidate for a range of applications, potentially leading to more efficient, faster, and smaller electronic devices. The ability to integrate SEG into existing semiconductor fabrication processes is particularly significant, as it paves the way for the more widespread use of graphene-based materials in the electronics industry.