The addition of SEM-HCl into the Sn perovskite precursor increases efficiency by 10.9%.

Researchers at Nanjing University of Posts & Telecommunications successfully increased efficiency and stability in lead-free perovskite solar cells by introducing an additive called semicarbazide hydrochloride (SEM-HCl) into the perovskite precursor. Tin (Sn) perovskites are being explored as an alternative to lead-based perovskites in solar cells. They have promising optoelectronic properties, which are essential for efficiently converting sunlight into electricity.

One of the main issues with tin perovskites is the presence of Sn vacancies and under-coordinated Sn ions on their surfaces. These imperfections can create deep-level traps, leading to non-radiative recombination. Non-radiative recombination is a process where excited electrons lose energy without producing light or electricity, which reduces the efficiency of the solar cell. These traps also absorb nucleophilic O2 (oxygen) molecules, reducing the efficiency and stability of the device.

The addition of semicarbazide hydrochloride (SEM-HCl) into the perovskite precursor addresses these challenges. SEM-HCl, with a functional group N–C=O, helps to fabricate high-quality tin perovskite films with a low concentration of deep-level trap densities. By reducing these trap densities, the interaction between photogenerated carriers (electrons and holes created when light hits the solar cell) and adsorbed oxygen molecules is minimised. This decreases the formation of superoxide entities, which are harmful to the cell’s efficiency and stability.

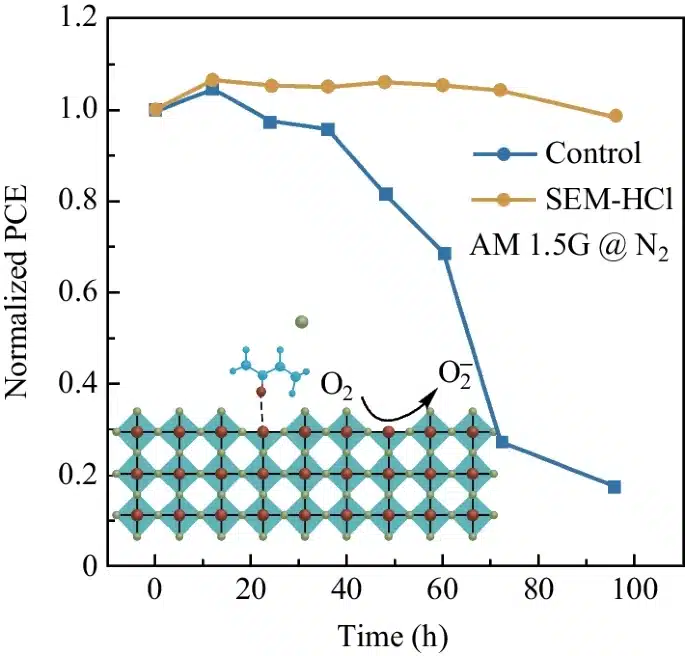

The devices created using SEM-HCl show a peak efficiency of 10.9%, showing significant improvement. These devices demonstrate improved stability, maintaining almost 100% of their initial efficiency after 100 hours of continuous operation under AM1.5 illumination conditions. AM1.5 refers to a standard solar spectrum that simulates sunlight on earth.

Choosing additive engineering over surface engineering provides a dual benefit. Firstly, because SEM-HCl is insoluble in common anti-solvents like chlorobenzene (CB), this approach proves to be more cost-effective. Secondly, additive engineering goes beyond surface interactions; it not only reduces the amount of uncoordinated Sn2+ ions on the surface but also adjusts the inherent Sn deep-level defects. This approach offers advantages in terms of both cost-efficiency and enhanced material properties.