New MRI scanners built specially for baby health diagnosis is more convenient than the big, very heavy liquid helium cooling-based ones

Current MRI scanners weigh around eight tonnes and therefore need to be located on floors that can take their weight. This means either to build specially reinforced floors or locating them in a basement. They also require ca. 40 square metres for the scanner and all the support equipment. Lastly, they need to be supercooled with liquid helium, which needs special handling.

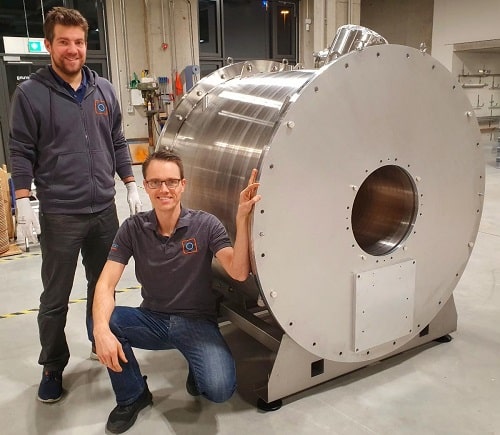

Neoscan Solutions has now invented an MRI scanner that is much smaller and lighter than an ordinary MRI scanner. It is advantageous because it could be placed directly in the children’s ward of the hospital. Key to the much smaller design is the use of digitisers and Arbitrary Waveform Generators (AWGs) by Spectrum Instrumentation that offer sub-nanosecond, coherence precision to generate the scanner signals and capture the results.

“Having worked with MRI scanners for many years, I recognised the problem,” explained Dr Stefan Roell, Founder of Neoscan Solutions in Germany. “Scanning a sick child usually means a long journey out of the ward to the scanner and babies may need support equipment that is not easily transportable. Because of this, sometimes an MRI scan is not even done. We have designed an MRI scanner specifically for newborns and infants which means that the hole in the middle is only 30cm in diameter, not 60cm. As a result, the scanner is much smaller (170cm x 150cm x 110cm) and can go through standard doorways. With a weight of only 2000 kg, it can be located on standard floors. Carrying a sleeping baby only a few meters to the MRI is a big advantage, saving a long journey through the building and the need for sedatives to keep the baby motionless for the scan.”

New Innovations Made

The technology and field strength of the Neoscan machine is identical to current scanners so that no new clinical studies are required to validate it. To match well-defined specifications, several enhancements were done.

To shrink the size, the team had to first develop a dry magnet that would create the standard 1.5 Tesla field inside the hole, but without requiring liquid helium. This is done by an inner, cylindrical magnet generating 2.5T and then an outer cylindrical magnet that counteracts the inner field to provide strong, active magnet shielding so that there is no stray magnetic field left beyond about 1m from the device’s cover.

The second innovation was in control electronics. Current MRI scanners typically require three big racks of specially developed electronics, that have been custom designed and built by the MRI manufacturer. So to tackle the problem, the team used a PC, which ran Neoscan’s software and also created high-end measurement PC cards from Spectrum Instrumentation. The signals for the MRI are generated by the M4i.6620-x8 and M2p.6546-x4 AWGs and then analysed using an M2p.5968-x4 digitizer. The system uses Spectrum’s SCAPP software drivers that enable a graphics processor with 5000 cores to perform the parallel processing, instead of using only 8 or 16 cores of a normal CPU.

For MRI, there must be phase coherence in the 64MHz signals, otherwise there will be cancellation effects. In practice, that means that the AWG and matching digitiser have to have sub-nanosecond coherence precision.

Neoscan will be shortly installing its first devices in German hospitals where it can be seen in operation by prospective customers as it takes images of babies. The certification process with a CE mark is expected to be completed before the end of 2021.

Dr Roell concluded by saying: ” I think it is a very elegant solution that could be used for many other complex machines such as CT scanners and Ultrasound machines, especially as it enables innovative new approaches to be easily tried and evaluated just through software changes.”