The discovery opens new avenues for manufacturing large quantities and thus reduce the tediousness of labour

While developing a new device or technology, engineers and scientists painstakingly spend long hours experimenting with various materials and assembling different parts before testing and manufacturing. Particularly, for nanomaterials, everything must be assembled carefully.

Now with the help of a tech developed by scientists from the University of Chicago, Cornell University and the University of Michigan, current manufacturing techniques will get a new makeover.

“This process is fully automated—you can program it and walk away,” said Andrew Mannix, assistant professor at Stanford University and former University of Chicago Kadanoff-Rice postdoctoral fellow. “Previously, if you wanted to try 10 different permutations of materials, it would all be done by hand, which is weeks of labour. We can now do this in an hour. We hope this opens new lines of inquiry in this exciting field by reducing the tediousness of labour.”

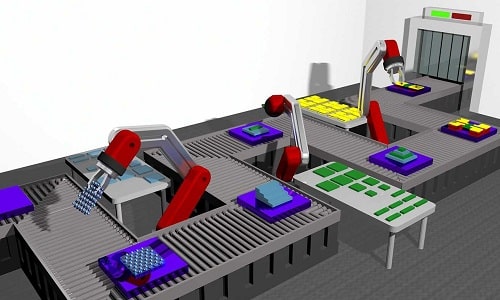

Automated assembly line

As per the scientists, stacking thick sheets of ordinary materials on top of each other produces a unique behaviour. For instance, when two layers of carbon are stacked on top of each other at a certain angle, the combination exhibits superconductivity.

“If you can take layers (of 2D materials) and stack them with control over the crystal orientation, you can get some really beautiful new physics, because the interactions between the layers are modified,” said Andrew Mannix.

However, the discovery process is slow, because scientists must first painstakingly assemble these combinations and test them one by one.

So to address this problem, the scientists aimed at automating the process. They wanted to make a tiny assembly line. This was achieved by figuring out a way to precisely cut the sheets into the exact desired shapes (without breaking them) and making a robot “hand” capable of manoeuvring these extremely fragile sheets into their correct positions.

With this system, the scientists were able to program their assembly line to make a material structure with dozens of different layers, walk away, and come back to a finished sample ready to test in a matter of minutes.

Not only is the system very precise, but it also offers extensive options for customisation, including the ability to rotate each successive sheet at different angles.

“This should speed up the pace of discovery considerably. It’s kind of like the difference between handwriting a book letter by letter versus using a printing press,” said Jiwoong Park, professor at the Department of Chemistry and the Pritzker School of Molecular Engineering, University of Chicago.