The recent discovery could be used in applications, from self-powered wearable devices and sensors to lightweight aircrafts and vehicles

It is encouraging to see the progress in the development of efficient and powerful solar cells. Materials exhibiting ferroelectricity, flexibility and impermeability are some of the few discovered recently.

Contributing to the list is a new photovoltaic material called Transition Metal Dichalcogenides or TMDs developed by researchers at Stanford University that promises to absorb high levels of sunlight and consequently supply a generous amount of power.

“Imagine an autonomous drone that powers itself with a solar array atop its wing that is 15 times thinner than a piece of paper,” said Koosha Nassiri Nazif, a doctoral scholar in electrical engineering at Stanford.

“That is the promise of TMDs.”

According to Krishna Saraswat, professor of electrical engineering at Stanford, silicon dominates the solar market these days. Although widely used for fabricating semiconductors, they are not perfect for all applications. Electronics in wearable devices, sensors or aerospace and electric vehicles need to be flexible, lightweight and eco-friendly. And therefore the need to discover new materials is necessary.

So how do TMDs intend to fulfil that purpose?

Firstly, the TMD-based solar panel prototype developed by the Stanford researchers promises to achieve a 27 per cent efficiency upon optical and electrical optimisations, on par with silicon-based solar panels.

Secondly, the prototype realises a 100-times greater power-to-weight ratio for movable applications like drones, electric vehicles and charging of other such devices.

Finally, the specific power produced by the prototype is 4.4 watts per gram, which gives a tough competition to other thin-film solar cells, including other experimental prototypes.

“We think we can increase this crucial ratio another ten times through optimisation,” Saraswat said, hoping to increase the current capacity to a remarkable 46 watts per gram.

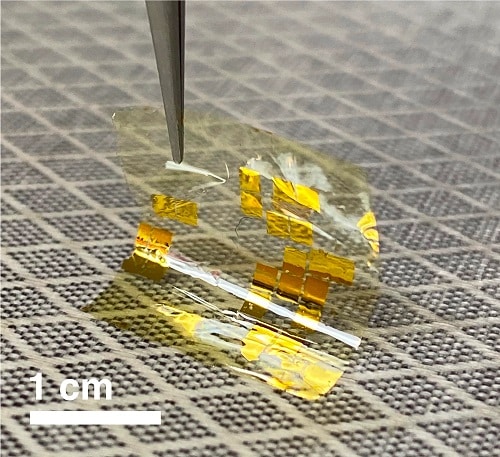

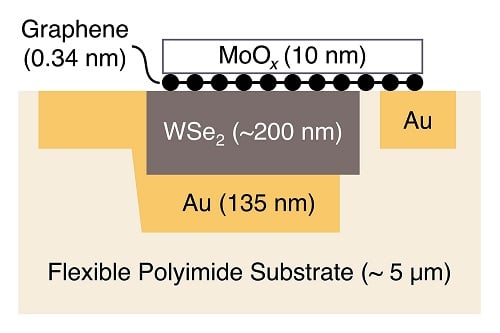

The Stanford team built a prototype of an array just a few hundred nanometers thick that included a photovoltaic TMD tungsten diselenide and contacts of gold spanned by a layer of conducting graphene that was just a single atom thick. All that was sandwiched between a flexible, skin-like polymer and an anti-reflective coating for improved light absorption.

When fully assembled, the TMD cells are less than six microns thick – about that of a lightweight office trash bag. It would take 15 layers to reach the thickness of a single piece of paper.

In addition to the above advantages, the biggest benefit lies in TMD’s impressive thinness, which minimises the material usage and cost along with making the solar cells lightweight and flexible enough to be moulded into irregular shapes.

While thinness, lightweight and flexibility are all highly desirable goals, TMDs present other advantages such as stability and reliability over the long term.

As for being eco-friendly, TMDs contain no toxic chemicals and are biocompatible, enabling safe implementation in wearable applications requiring direct contact with human skin or tissue.

Despite multiple advantages, TMDs have their share of challenges. The process of transferring an ultrathin layer of TMD to a flexible, supporting material often damages the TMD layer. Under such circumstances, mass production is not viable.

So, Alwin Daus, senior researcher at RWTH Aachen University and a contributor to the study on TMDs, devised a process that allowed the transfer of thin TMD solar arrays to a flexible substrate, which involved transferring the layer of atomically thin graphene onto a flexible substrate just a few microns thick.

By bending and testing the flexibility and robustness of the embedded TMDs in the flexible substrate, the researchers concluded that the material’s durability can provide a new direction to solar technology.

For detailed information, read here