Physicists have discovered a new way to coat soft robots in materials that allow them to move and function in a more purposeful way

Robots have proved themselves to be great assistants in performing humanly inaccessible tasks. Their ability to work continuously in harsh conditions makes them ideal companions for people involved in medical and rescue operations.

A few years ago, a flexible robot was devised for lifting heavy loads. Equipped with a complex system of gears and motors, the robot resembled a growing plant that could move in any direction.

Now researchers at the University of Bath have discovered a new technique to coat soft robots that allows them unrestricted movement to function more purposefully.

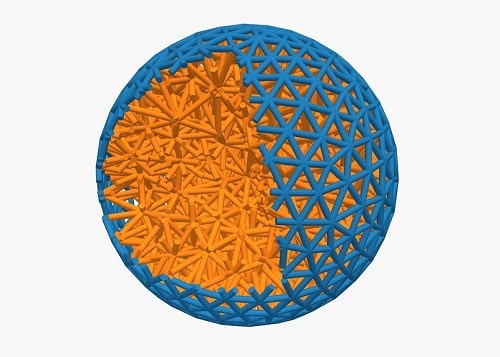

The surface of an ordinary soft material always shrinks into a sphere. For instance, the formation of water beads into droplets occurs because the surface of liquids and other soft material naturally contracts into the smallest surface area possible – i.e. a sphere. But active matter can be designed to work against this tendency. Example: a rubber ball that’s wrapped in a layer of nano-robots, where the robots are programmed to work in unison to distort the ball into a new, pre-determined shape.

It is hoped that active matter will lead to a new generation of machines. Modelling on ‘active matter’ may allow the possibility to determine the shape, movement and behaviour of a soft solid not by its natural elasticity but by human-controlled activity on its surface.

So, instead of being governed by a central controller (how current robotic arms are operated), these new machines are made from many individual active units that cooperate to determine the machine’s movement and function. This is akin to the workings of our biological tissues, such as the fibres in the heart muscle.

“Active matter makes us look at the familiar rules of nature – rules like the fact that surface tension has to be positive – in a new light. Seeing what happens if we break these rules, and how we can harness the results, is an exciting place to be doing research,” said Dr Jack Binyish, research staff, Department of Physics at the University of Bath.

For the study, the researchers developed theory and simulations that described a 3D soft solid whose surface experiences active stresses. They found that these active stresses expand the surface of the material, pulling the solid underneath along with it, and causing a global shape change. The researchers found that the precise shape adopted by the solid could then be tailored by altering the elastic properties of the material.

“This study is an important proof of concept and has many useful implications. For instance, future technology could produce soft robots that are far squishier and better at picking up and manipulating delicate materials,” said Dr Anton Souslov, lecturer, Department of Physics at the University of Bath.

Using this concept, soft, flexible machines powered by robots embedded in their surface could be created. One application could be drug delivery by shaping the size of capsules and coating the surface of nanoparticles in a responsive, active material. This in turn could have a dramatic effect on how a drug interacts with cells in the body.

In the next phase of this work – which has already begun – the researchers will apply this general principle to design specific robots, such as soft arms or self-swimming materials. They will also look at collective behaviour – for example, what happens when you have many active solids, all packed together.