A team of researchers from U.K. has developed a unique near-infrared light imaging technique to capture the first cross-sectional images of carbon dioxide in the exhaust plume of a commercial jet engine

The aviation industry is the major contributor to global carbon dioxide emissions. Until now it was impractical to image turbine combustion on test rigs containing a large airplane engine. Therefore, four instrumentation research groups in the U.K. came together to integrate their knowledge in gas species measurement in harsh environments, chemical species tomography, and optical source development. They developed near-infrared light imaging techniques to capture the dynamic processes of combustion. This new state-of-the-art technology could assist in enhancing turbine combustion research targeted at improving engines and aviation fuels that are more environmentally friendly.

“This approach, which we call chemical species tomography, provides real-time spatially resolved information for carbon dioxide emissions from a large-scale commercial engine,” said research team leader Michael Lengden from the University of Strathclyde in the U.K. “This information has not been available before at this industrial scale and is a big improvement over the current industry-standard emissions measurement, which involves taking gas from the exhaust to a gas analyzer system in a different location.”

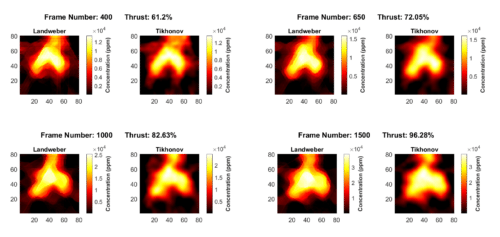

Researchers worked for many years to fine-tune signal-to-noise ratios, data acquisition methods, imaging techniques, and optical sources, the researchers invented the first facility capable of acquiring industrial emission measurements at the large scale of a commercial airplane engine. The researchers used a large-scale setup to do chemical species tomography of carbon dioxide produced by combustion in a modern Rolls-Royce Trent gas engine turbine. These engines are typically used on long-haul aircraft and contain a combustor with 18 fuel injectors arranged in a circle. The researchers experimented by recording data at frame rates of 1.25 Hz and 0.3125 Hz while the engine was functioning over the full range of thrust. The resulting images exhibited all thrust level and ls, a ring structure of high carbon dioxide concentration was present in the central region of the engine. There was also a raised region in the middle of the plume, which was likely due to the engine’s shape.

“The very refined measurement methodology we used demanded an exquisite knowledge of carbon dioxide spectroscopy and the electronics systems that provide very precise data,” said Lengden. “Also, a very sophisticated mathematical method had to be developed to compute each chemical species image from the measured absorptions of the 126 different beams we used.”

Now researchers aim to work on a new instrument to enable quantitative measurement and imaging of other chemicals provided by turbine combustion in both the aerospace and industrial power generation sectors and to capture images of temperature.

Click here for the Published Research Paper