The printer can handle a variety of materials, making it suitable for diverse applications like microphones, ultrasound probes, and solar panels.

A team of researchers from The Hong Kong University of Science and Technology (HKUST), in collaboration with the City University of Hong Kong, has developed a cost-effective microprinter that significantly speeds up the production of piezoelectric films. These films are essential in microelectromechanical systems (MEMS) for sensors and medical devices.

This innovative printing technique successfully creates free-standing nanoparticles, films, and micro-patterns using lead zirconate titanate (PZT), a piezoelectric material. The produced PZT films demonstrate a high piezoelectric strain constant of 560 pm V−1, which is one to two times greater than current leading technologies.

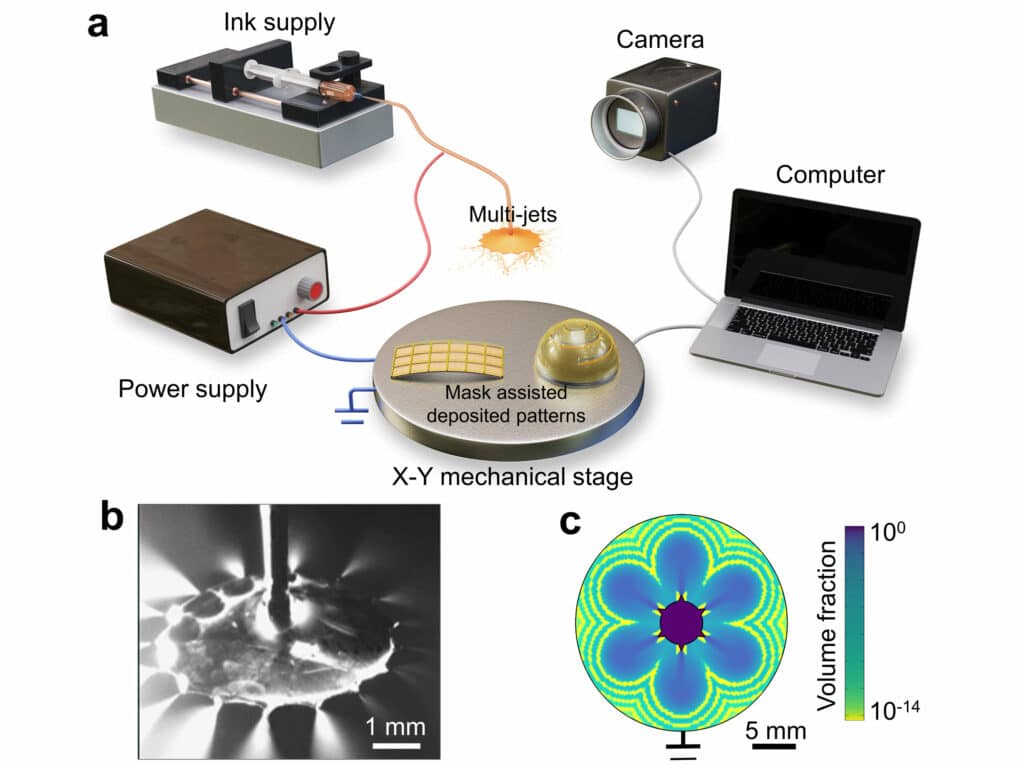

The printer uses an electrostatic field for precise and fast pattern creation on surfaces, enhancing mass production capabilities and potentially lowering costs. It operates by propelling ink onto a platform, forming micro patterns quickly and with minimal waste.

The microprinter features a multiplexed tip jetting mode and a substantial layer-by-layer depositing area, enabling it to achieve depositing speeds of up to 109 μm³ s⁻¹. This method can produce a 10 μm-thick PZT film on a 4-inch Si wafer in just 10 minutes, a process 100 times faster than current techniques.

The micro-printer, described in Nature Communications, was designed by Prof. Yang Zhengbao and his team. Priced at HKD 6,000, it offers a cost-efficient solution for large-scale production and is ready for commercial use. The team is seeking commercial partnerships to further expand its applications and address current micromanufacturing limitations in piezoelectric element production.