New technique fully reclaims all-carbon-based transistors while retaining future functionality of the materials

As people worldwide adopt more electronics into their lives, there’s an ever-growing pile of discarded devices that either doesn’t work anymore or have been cast away in favour of a newer model. The problem is only going to get worse as the world upgrades to 5G devices and the Internet of Things (IoT) continues to expand.

Part of the problem is that electronic devices are difficult to recycle. Large plants do employ hundreds of workers who are involved in disintegrating bulky devices. But while scraps of copper, aluminium and steel can be recycled, the silicon chips can’t.

To come up with an innovative solution, engineers at the Pratt School Of Engineering, Duke University have developed fully recyclable printed electronics using carbon-based inks.

“Silicon-based computer components are probably never going away. We don’t expect easily recyclable electronics like ours to replace the technology and devices that are already widely used,” said Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke. “But we hope that by creating new, fully recyclable, easily printed electronics and showing what they can do, that they might become widely used in future applications.”

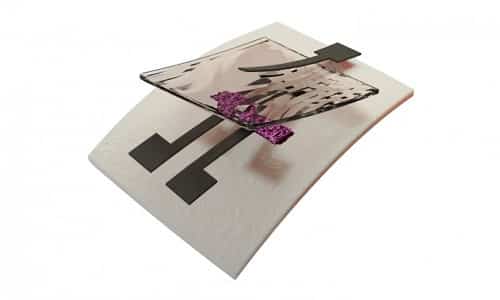

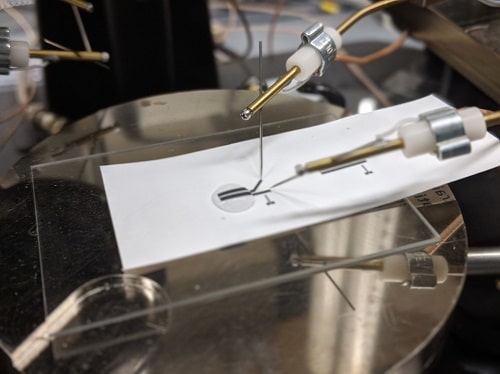

To demonstrate his finding, Franklin and his laboratory assistants developed a completely recyclable, fully functional transistor made out of three carbon-based inks that can be easily printed onto paper or other flexible, environmentally friendly surfaces. Carbon nanotubes and graphene inks are used for the semiconductors and conductors, respectively. While these materials are not new to the world of printed electronics, Franklin says, the path to recyclability was opened with the development of a wood-derived insulating dielectric ink called nanocellulose.

“Nanocellulose is biodegradable and has been used in applications like packaging for years,” said Franklin. “And while people have long known about its potential applications as an insulator in electronics, nobody has figured out how to use it in a printable ink before. That’s one of the keys to making these fully recyclable devices functional.”

Nanocellulose Experimentation Success

The researchers devised a method for suspending nanocellulose crystals that were extracted from wood fibres. The sprinkling of a little table salt yielded an ink that performed as an insulator in the printed transistors. Using the ink in an aerosol jet printer at room temperature, the team showed that the all-carbon transistors performed well enough for use in a wide variety of applications, even six months after the initial printing.

To show the recyclability of the design, the devices were immersed in a series of baths and gently vibrated using sound waves. By centrifuging the resulting solution, the carbon nanotubes and graphene are sequentially recovered with an average yield of nearly 100%. It was possible to reuse both materials in the same printing process while losing very little of their performance viability. And because the nanocellulose is made from wood, it can simply be recycled along with the paper it was printed on.

Compared to a resistor or capacitor, a transistor is a relatively complex computer component used in devices such as power control or logic circuits and various sensors. Through demonstrating a fully recyclable, multifunctional printed transistor, Franklin hopes to make a first step toward the technology being commercially viable for simple devices to large building needing thousands of simple environmental sensors for monitoring purposes.

“Recyclable electronics like this aren’t going to go out and replace an entire half-trillion-dollar industry by any means. We’re certainly nowhere near printing recyclable computer processors,” said Franklin. “But demonstrating these types of new materials and their functionality is hopefully a stepping stone in the right direction for a new type of electronics lifecycle.”

The work appears in the journal Nature Electronics.