To remove the problems of using flat panels detectors for X-rays, key design rules have been identified for making curved X-ray detectors

The use of digital flat panel detectors allows quick examination of X-rays and enables immediate decision-making for medical diagnosis as compared to examining X-rays with sensitive photographic films.

But not all human body shapes are the same; some are complex than others.

And for such body types, flat panels are not suitable as they lead to distortion around the edges of images.

Flat panels also prevent an accurate registration of the X-ray that is delivered, a key feature towards enabling safer radiation therapy and minimising secondary tumours.

Although several efforts were made to create flexible detectors, they were largely unsuccessful owing to the brittle characteristics of the rigid inorganic semiconductors used to make them. Despite having achieved a certain level of curvature by using a thinner layer of semiconductor, the image quality severely degraded, compromising its performance.

Now researchers from the Advanced Technology Institute at the University of Surrey, in collaboration with the University of Bologna, the National Physical Laboratory and the Sheffield University, have laid out the specifications for a special class of “inorganic in organic” semiconductors.

By tuning the molecular weight of the bismuth oxide nanoparticle sensitised organic semiconductors to lengthen the polymer chains, the researchers are paving the way towards making more robust, curved digital detectors or digital films having high sensitivity.

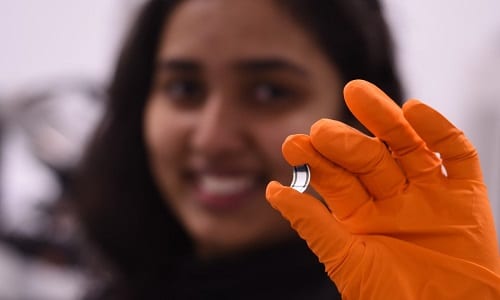

“Our curved detector concept has shown exceptional mechanical robustness and enables bending radii as small as 1.3mm,” said Prabodhi Nanayakkara, research team member and PhD student at the University of Surrey.

“The use of organic or ‘inorganic in organic’ semiconductors is also far more cost-effective than conventional inorganic semiconductors made from silicon or germanium, which require expensive crystal growth methods. Our approach potentially offers a significant commercial advantage.”

Professor Ravi Silva, Director of Surrey’s Advanced Technology Institute, added, “The technology we’re demonstrating will help create a revolutionary new high sensitivity X-ray detector that is scalable, due to the design and materials adopted. This technology has huge potential in medical applications and other X-ray uses.”

“We’re working with a spinout company, SilverRay, and hope to turn this technology into the X-ray detector of choice for high sensitivity, high resolution, flexible large area detectors.”