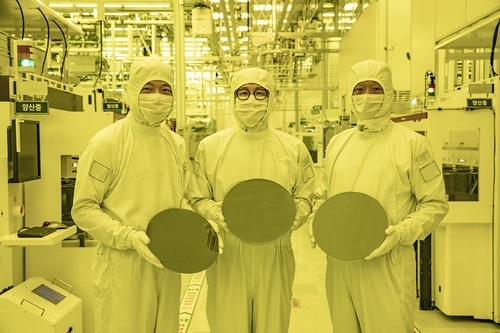

Samsung has announced that it has started manufacturing 3-nanometer semiconductors in large quantities, upping its game in the most cutting-edge chipmaking process node.

The next-generation 3nm circuits are constructed using Gate-All-Around (GAA) technology, which according to Samsung will eventually enable space reductions of up to 35% while delivering 30% higher performance and 50% less power usage than the current FinFET process. According to Samsung, its first-generation 3nm process node results in a 16 percent area reduction, a 23 percent increase in performance, and a 45 percent decrease in power usage.

More clients are anticipated to come to Samsung in search of cutting-edge and potent semiconductors that would permit quicker, more effective technological items thanks to the development in advanced chipmaking technology. “Samsung has grown rapidly as we continue to demonstrate leadership in applying next-generation technologies to manufacturing,” Choi Si-young, president and head of Samsung’s foundry business, said. “We will continue to develop innovative technology and work to secure a mature technology process fast,” he said.

Since the third quarter of last year, the largest memory chip manufacturer in the world has collaborated with its partners, including American silicon design company Synopsys and German technology company Siemens, both of which are members of Samsung Advanced Foundry Ecosystem (SAFETM), to offer its foundry customers chip design infrastructure and other services.

The 2nm process node is still in the early phases of development, according to Samsung, the second-biggest foundry and the world’s largest manufacturer of memory chips, which has mass production set for 2025. Compared to a year ago, Samsung’s foundry business is anticipated to rise by about 40% this year, vs the forecast industry growth rate of 25%.

“Samsung is receiving more foundry orders than it can handle. What matters is how well and quickly the company can meet demand through long-term planning and adequate investment.”