“This is something that has never been done before, so this is a breakthrough in the 3D printing of small channels”

Researchers at the University of Southern California’s Viterbi School of Engineering have devised a highly specialised 3D-printing process that permits microfluidic channels to be built on chips at a microscale previously unattainable.

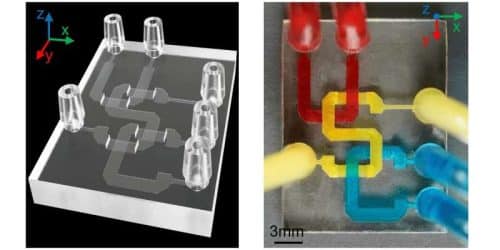

Microfluidic devices are small testing tools comprised of microscopic channels carved into a chip that allow biomedical researchers to evaluate the properties of liquids, particles, and cells at the microscale. In fields like cancer, diabetes, and now COVID-19, they’re critical to medication development, diagnostic testing, and medical research.

The study, led PhD graduate Yang Xu and Professor Yong Chen at Purdue University, was published in Nature Communications in collaboration with Professor Noah Malmstadt and Professor Huachao Mao. The researchers employed vat photopolymerization, a sort of 3D printing process that uses light to manipulate the conversion of liquid resin material into its solid state.

“This is the first time we’ve been able to print something where the channel height is at the 10 micron level; and we can control it really accurately, to an error of plus or minus one micron. This is something that has never been done before, so this is a breakthrough in the 3D printing of small channels,” Chen said.

When it comes to microfluidic devices, vat photopolymerization has several drawbacks in terms of creating the tiny wells and channels needed on the chip. The UV light source often penetrates deeply into the leftover liquid resin, curing and solidifying material within the device’s channels, causing the finished device to clog.

The team created a novel auxiliary platform that travels between the light source and the printed device, keeping the light from hardening the liquid within the walls of a channel, allowing the channel roof to be placed separately to the device’s top. The remaining resin in the channel would still be liquid and could be flushed away after the printing process to create the channel space.

“There are so many applications for microfluidic channels. You can flow a blood sample through the channel, mixing it with other chemicals so you can, for example, detect whether you have COVID or high blood sugar levels,” Chen said. He said that the new 3D printing platform’s microscale channels enabled various uses, such as particle sorting. This could have a huge impact on cancer detection and research.