Researchers have successfully integrated the future microfluidic systems with robotic systems enabling one-for-all devices.

Researchers have been scaling instruments to make them more handy. The advancement of technology is just a result of that. The concept of lab-on-a-chip is something similar. Testing certain chemicals using just a microchip filled with very small amounts of chemicals known as microfluidic devices has been in use for quite some time now. Yet the technology to implement the same on a mass level is a bit of a challenge.

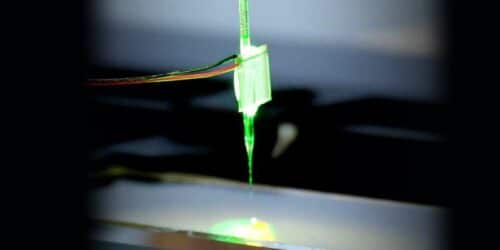

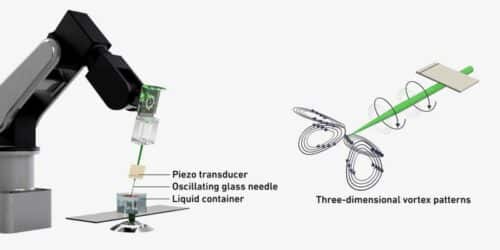

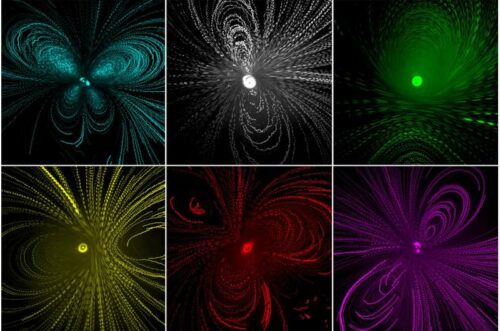

Researchers at ETH Zurich have developed an ultrasonically actuated glass needle that can be attached to a robotic arm. This lets them pump and mix minuscule amounts of liquid and trap particles. They have combined conventional robotics and microfluidics. The device comprises a thin, pointed glass needle and a piezoelectric transducer that causes the needle to oscillate. Similar transducers are used in loudspeakers, ultrasound imaging and professional dental cleaning equipment. The ETH researchers can vary the oscillation frequency of their glass needle. By dipping the needle into a liquid they create a three-dimensional pattern composed of multiple vortices. Since this pattern depends on the oscillation frequency, it can be controlled accordingly.

The researchers demonstrated how this method can capture not only inanimate particles but also fish embryos. They believe it should also be capable of capturing biological cells in the fluid. They also succeeded in using their robot-assisted acoustic device to trap fine particles present in the fluid. This works because a particle’s size determines its reaction to the sound waves. Relatively large particles move towards the oscillating glass needle, where they accumulate. The scientists were able to pump fluids through a mini-channel system by creating a specific pattern of vortices and placing the oscillating glass needle close to the channel wall.

“Mixing and pumping liquids and trapping particles—we can do it all with one device,” Ahmed says. This means tomorrow’s microfluidic chips will no longer have to be custom-developed for each specific application.

Reference : Jan Durrer et al, A robot-assisted acoustofluidic end effector, Nature Communications (2022). DOI: 10.1038/s41467-022-34167-y