Engineers design fluidic logic elements into garments to help people with functional limitations perform tasks without electronic assistance.

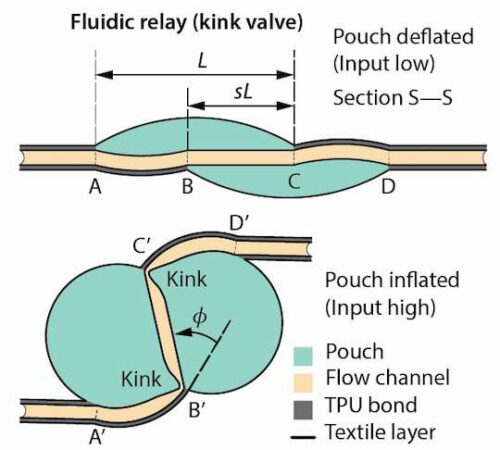

Engineers at Rice University have designed textile-based pneumatic computers capable of digital logic, onboard memory and user interaction. The concept works on how air flows through a series of “kinked” channels to form bits, the 1s and 0s in computer memories. The idea is to harvest energy from a textile based logic gates that support pneumatic actuators.

“The idea of using fluids to construct digital logic circuits is not new,”said Daniel Preston, Assistant Professor at Mechanical Engineering Department Rice University. “And in fact, in the last decade, people have been moving towards implementing fluidic logic in soft materials, things like elastomers. But so far, no one had taken the step to implement it in sheet-based materials, a feat which required redesigning the entire approach from first principles.”

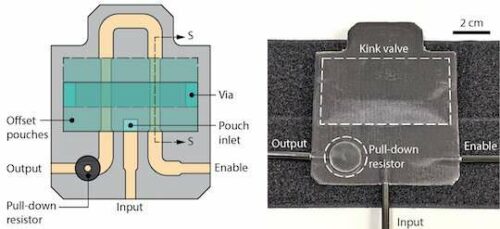

An inverter, basically a ‘NOT’ gate, sits at the center of the concept. The pneumatic gate works with “high” or “low” air pressure, the same as in a gate, on or off(1 or 0). “We think of the logic element as, at its most fundamental level, containing both a relay and a fluidic resistor,” said Anoop Rajappan, a Rice postdoctoral fellow and lead author of the paper. “These would be equivalent to having an electronic relay or transistor paired with the resistor, which is the foundation of typical transistor-resistor logic.”

The pressure-controllable valves in the pneumatic system work on a mathematically designed kink geometry as described by Preston. These pressure controllable valves cut the flow of air the same way a bent garden hose stops water. These valves can handle 20,000 on-off cycles and 1 million flex cycles, as well as 20 cycles in a standard household washing machine.

The system is aimed to help people with functional limitations with their day-to-day tasks.