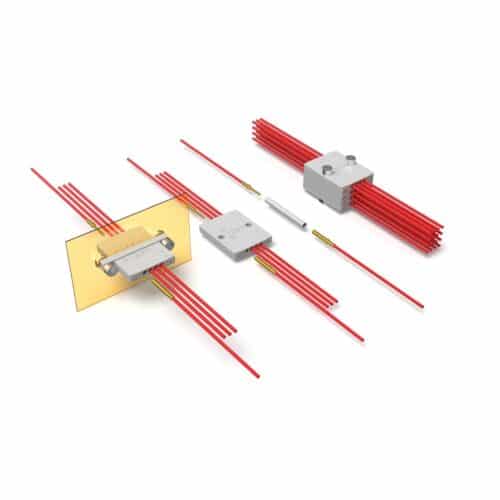

A series of wire-connecting solutions that is designed to replace manual splicing processes in challenging environments.

Littelfuse, Inc. have launched a C&K SpaceSplice series wire connecting solution which the company claims to be designed to replace manual splicing processes in harsh environments. According to the press release issued by the company, the connectors facilitate the joining of two wires through a D*MA crimpable and removable contact technology, ensuring easy installation and removal. The company says that SpaceSplice is designed to accommodate the most commonly used wire gauges, minimising costs and ensuring the utilisation of only the necessary wires. The connector is suited for various applications, including military/aerospace scenarios such as satellites, launchers, and payloads. According to the company’s claim, the connectors prove beneficial in connecting components like heaters, thermistors, and multilayer insulators (MLIs), as well as in other challenging environments where durability is essential.

The press release highlights that the connectors are compatible with a wide range of cable gauges, accommodating popular sizes from American Wire Gauge (AWG) 20 to AWG 30. The company claims that the connectors offer resistance to radiation and high temperatures, making them suitable for challenging environments. Moreover, the solution complies with the specifications outlined by the European Space Agency (ESA/ESCC 3401/097), meeting stringent industry standards and ensuring its reliability and quality.

“The SpaceSplice connectors design provides a high-reliability solution that replaces manual splicing processes, offering a standardised alternative that is easy to use, reducing labour time and cost while increasing reliability,” said Rémi Antoine, Global Product Manager at C&K Aerospace, now part of Littelfuse.

Some of the technical specifications of the wire connecting solution include:

- Working Voltage – 1 way: 300 Vrms at sea level – 250 Vrms at 33000m altitude

- Working Voltage – 4 ways: 250 Vrms at sea level – 200 Vrms at 33000m altitude

- Rated Current Contact Standard Density Size 20/20: 7.5 A

- Rated Current Contact Standard Density Size 20/26: 3.0 A

- Contact Resistance (Rated Current): 5.0 mΩ max

- Insulation Resistance (500 VDC): 5000 MΩ min

- Voltage Proof – 1 way: 1250 Vrms / 2.0 mA leakage current

- Voltage Proof – 4 ways: 1000 Vrms / 2.0 mA leakage current

- Temperature Range: -55°C to 125°C

- Residual Magnetism Level: 200 Gamma (NMB)