New technology is expected to mass produce next-generation, customised e-textiles for healthcare, industrial and military use.

The world’s first-ever development of customised electronic textiles (e-textiles) utilising graphene with a multimodal approach has been achieved. Multimodal refers to exchanging information through diverse sensory interfaces, including visual and auditory sensations.

In the realm of electronic textiles (e-textiles), a collaborative research team led by Principal Researcher Soongeun Kwon from the Department of Nano Manufacturing Technology at the Korea Institute of Machinery and Materials (KIMM), an institution falling under the purview of the Ministry of Science and ICT. Additionally, Professor Young-Jin Kim from the Department of Mechanical Engineering at the Korea Advanced Institute of Science and Engineering (KAIST) played a pivotal role in this development. This team pioneered the world’s first graphene-based customised e-textiles and shared their findings in the prestigious scientific journal “ACS Nano,” known for its impressive impact factor of 18.027.

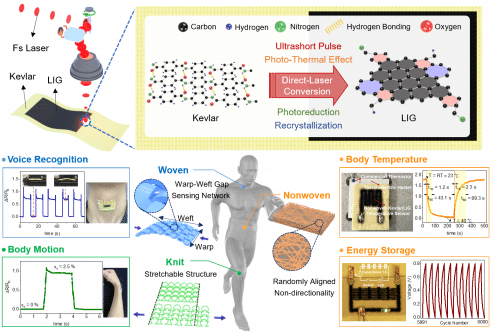

The collaborative research team achieved the fabrication of graphene-based e-textiles using laser direct patterning technology, avoiding the use of harmful chemicals or optical masks typically employed for patterning. This innovation involved the creation of laser-induced graphene (LIG) directly on the e-textiles. Laser direct patterning technology creates patterns on functional materials by directing a laser beam onto the garment’s surface, causing the conversion of materials only in the areas exposed to the laser. When a high-power laser is applied to the surface of a polymer film or garment, the optical energy transforms into thermal energy, leading to the instantaneous formation of carbon material, specifically in the irradiated regions. This resulting material, closely resembling graphene, a two-dimensional nanomaterial, is called laser-induced graphene (LIG) due to its crystal structure similarity.

Traditionally, e-textiles have been produced using two main approaches: one involves applying conductive ink to fabric to create electrically conductive textiles, which are then woven with standard materials. The other method entails adding a thin, functional layer to regular fabrics. These conventional methods have limitations in terms of design flexibility and involve complex processes. Additionally, there is a risk of harmful chemicals being released during manufacturing, which hampers mass production capabilities.

Femtosecond Laser Processing Technology

This technology makes high-quality Laser-Induced Graphene (LIG) materials with top-tier electrical conductivity effortlessly produced by directing a laser beam onto fabric surfaces. An essential benefit of this approach lies in its eco-friendliness, as it eliminates the need for chemicals or additional processes in manufacturing e-textiles. Furthermore, the electrical conductivity of LIG electrodes has been achieved by applying femtosecond laser processing technology. Femtosecond laser processing technology involves fabricating materials using ultrashort laser pulses characterised by highly brief pulse width and high peak power. In contrast to other laser types, this technology minimises material damage and is particularly valuable for creating high-resolution patterns.

This newly developed technology holds promise for various applications in the future, including manufacturing industrial and military clothing for personal health monitoring and producing customised “smart” garments within the healthcare sector. The researchers claim that this technology emerged from a meticulous analysis of conventional fabric structures, which were then translated into advanced graphene-based materials with ideal e-textile properties. This innovation is of significant importance, as it enables the mass production of customised e-textiles through an environmentally friendly and straightforward process. It’s worth noting that this research received support from the “development of nano-based ‘Omni-TEX’ manufacturing technologies” project, which is among KIMM’s foundational initiatives.