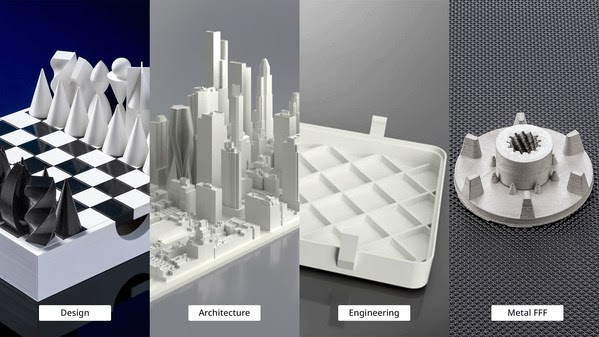

Ultimake has launched the beta for Ultimaker Cura 5.0, the latest version of its free, open source, slicing software during the Spring Showcase. Unique applications in design, architecture, engineering and metal 3D printing have been enabled by the enhanced slicing engine that sets a new threshold for finer and faster 3D prints. The newly developed variable line width capability of this slicing engine improves its ability to print thin walls and fine details. Parts printed with this engine will also be stronger. Other improvements include faster print profiles for owners of Ultimaker printers, support for Apple M1 chips, and more.

“Ultimaker Cura 5.0 represents the biggest leap forward in print quality that the software has ever seen. This is the start of a true revolution in 3D printing technology,” says Miguel Calvo, Chief Technology Officer (CTO) at Ultimaker. “We believe that even those who have looked at 3D printing before and concluded that it may not be ready for their use, today it is time for them to look again. Until now, you had to make your design work for 3D printing. It’s time to turn the table… from designing for 3D printing, to 3D printing for design.”

The most eye-catching improvements of Ultimaker Cura 5.0 are:

- Thinner walls and finer details

The new slicing engine in Ultimaker Cura 5.0 allows for the use of variable line width when slicing a 3D model to most accurately print fine details.

- Stronger parts

The variable line width capabilities of the new slicing engine in Ultimaker Cura 5.0 results in fewer gaps on the inside of printed parts, making them more solid, and therefore stronger. The improved printing of thin walls brings parts printed with Ultimaker Cura 5.0 closer to the strength of those produced using injection molding.

“Cura is evolving and there is much more freedom in the design for FFF, so the software is less of a limiting factor. Thin walls, and the kind of small design features that are often featured in injection molded parts, are created more efficiently and this results in applications being produced in an improved way in 3DP,” according to Steve Cox – Engineer and 3D printing advocate.

- Faster print profiles

Print profiles available to users of Ultimaker printers have been updated to make use of the improved capabilities of Ultimaker Cura 5.0 resulting in print time reductions of up to 20%.

New possibilities and new applications

The Showcase featured innovators and thought-leaders from the 3D printing community who demonstrated unique applications enabled by the newest version of Ultimaker Cura 5.0. It can be watched here for anyone who missed the original presentation of Cura 5.0.