Table of Contents

When working with Printed Circuit Boards (PCBs), it’s essential to understand the different techniques and components used in assembly. Surface-mount technology (SMT), surface-mount devices (SMD), and through-hole technology (THT) are three important concepts. Though they are related, they differ fundamentally in their processes and components.

What is Surface-Mount Technology (SMT)?

SMT (Surface-Mount Technology) is a method used to assemble electronic components directly onto the surface of a PCB. This process allows for higher component density, smaller sizes, and faster production compared to older methods like THT.

SMT Process Overview:

- Solder Paste Application: A stencil is used to apply a precise amount of solder paste onto the PCB’s pads.

- Component Placement: A pick-and-place machine positions SMD components onto the pasted pads.

- Reflow Soldering: The board is passed through an oven to melt the solder paste, creating a strong bond between the SMD and PCB.

What is a Surface-Mount Device (SMD)?

SMD (Surface-Mount Device) refers to the electronic component used in the SMT process. These components are designed specifically to be mounted on the surface of the PCB without the need for drilled holes.

Types of SMD Components:

- Resistors and Capacitors: Small, rectangular components often used in surface-mount designs.

- ICs (Integrated Circuits): Complex components that control various functions of the board.

- Diodes and Transistors: Semiconductor components commonly used in power regulation and switching circuits

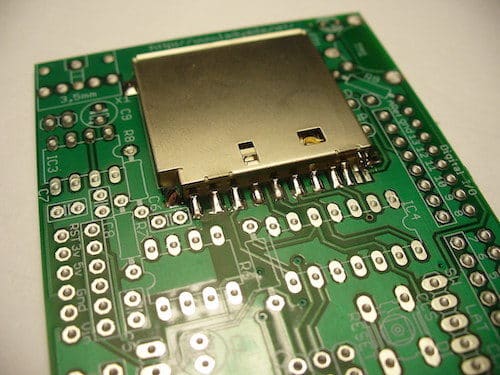

What is Through-Hole Technology (THT)?

THT (Through-Hole Technology) is an older method of placing electronic components onto a PCB by inserting the component leads through drilled holes in the board. This process is still commonly used for larger components that require a stronger mechanical bond.

THT Process Overview:

- Component Insertion: Leads of components (such as resistors, capacitors, or ICs) are inserted into pre-drilled holes.

- Soldering: The component leads are soldered to the pads on the opposite side of the board, either by hand or using a wave soldering process.

I like your world famous magazine (ELECTRONICS FOR YOU)

Thank You Prashant.

very nice arctical and very helpfully know about electronics and smt technology

Thank You for your feedback.

It is very useful for my studies

Thank you for your valuable feedback.