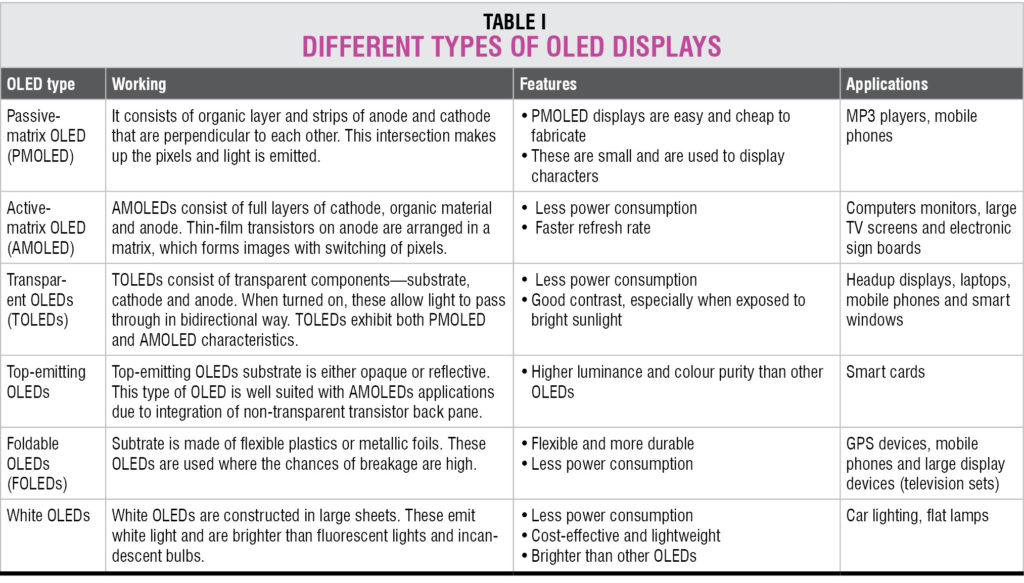

An overview of the current status of OLEDs along with different OLED types and their applications

Over the last few years, organic light-emitting diodes (OLEDs) have found promising applications in flat-panel displays, replacing cathode ray tubes (CRTs) or LED displays. Solid-state OLEDs make it easier to fabricate flexible displays.

The emission of light from materials in the presence of an electric field is called electroluminescence. In 1960s, a single crystal of anthracene helped to observe this phenomenon. Despite the huge quantum efficiency obtained with this organic crystal, no application has been reported with fascinating results. In 1987, Tang and Van Slyke from Kodak achieved efficient and low-voltage OLEDs from a p-n heterostructure device.

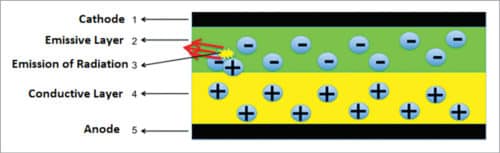

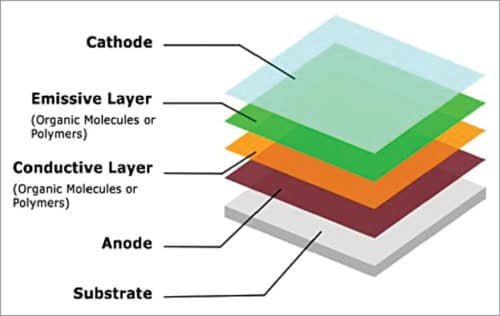

OLEDs are thin-film organic semiconductor light-emitting devices. These consist of a thin film of organic material sandwiched between two electrodes (anode and cathode) as shown in Fig. 1. Organic electroluminescent materials are contingent upon pi-conjugated molecules and are almost insulators. Light is generated when holes and electrons injected at electrodes recombine.

Anode is transparent and made of indium tin oxide. Cathode is reflective and made of metal. When an external potential is applied across electrodes, positive and negative charges (holes from anode and electrons from cathode) are injected. These electrons and holes shift inside the material and recombine to form excitons, emitting photons in the process.

Based on their number of layers, OLEDs can be classified as two-layer and three-layer OLEDs.

In two-layer OLEDs, electrons are injected from cathode into the lowest unoccupied molecular orbital. Simultaneously, holes are injected from anode into the highest occupied molecular orbital.

In three-layer OLEDs, the conductive layer is replaced with electron transport layer and hole transport layer.

Compared to LEDs and LCDs, OLEDs use wide-energy-gap semiconductors and exhibit singlet and triplet exciton radiation phenomenon.

Architecture of an OLED

An OLED consists of:

1. Substrate. Regarded as the base of an OLED, it is made up of a thin translucent glass or foil material.

2. Anode. It is also called as emitter. Its main function is to emit electrons when a voltage is applied across terminals.

3. Organic layer. The layer above anode is called organic layer. It contains conductive polymer made of hydrogen or carbon molecules.

4. Conductive layer. This layer is made of organic plastic molecules and helps to move holes from anode.

5. Emissive layer. This layer is made of organic materials that are different from those used in the conductive layer. It helps to transport electrons from cathode.

6. Cathode. Cathode is the topmost part of OLED displays. It injects electrons when a potential difference is applied across terminals.

Applications

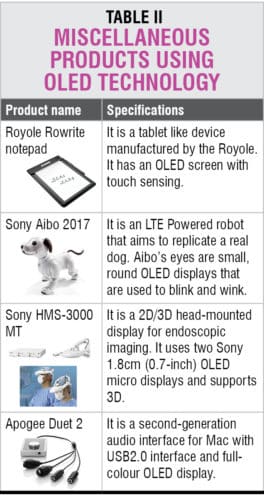

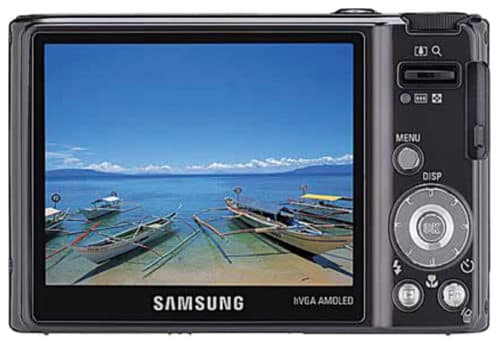

OLED displays are mainly used in digital devices such as high-end television systems, computer monitors, pocket-size systems such as Android phones, media players, digital cameras, portable gaming consoles and mini-screens. Such types of applications demand high reliability and readability. OLEDs fit in as these consume less power and provide high-quality display. The current OLED technology provides remarkable colour fidelity, high efficiency and operation stability.

Products available across different categories are listed below.

Mobile phones

Since year 2016 many mobile phones have been introduced with OLED screen, including Samsung A8+, Gionee S11S and M7 plus, Oppo A79 and R11 plus, OnePlus 5T, Google Pixel 2 and iPhone X.

OLED TV

TV display technology has evolved from LED to OLED and QLED. At present, all companies are working on OLED displays to make their products smart. OLED TV models include B&O BeoVision Eclipse, Loewe Bild 4, Bild 5 and Bild 9, Toshiba X97, Skyworth W9 Wallpaper OLED and S9E, Panasonic EZ950 and EZ1000, Sony XBR-A1E Bravia and Signage 65EE5PC. Some of the companies like LG have even categorised their TV displays into flat OLED display, curved OLED display and OLED wallpaper.

Digital cameras

Use of OLED displays in digital camera screens or electronic viewfinders is on the rise. The first OLED camera was Kodak LS633 in 2003. Today, there are a host of OLED models available like Canon Power Shot G1 X Mark III, Fujifilm GFX 50S and X-T2, Sony a99 Mark II and HX80, Panasonic DMC-FZ2500 and Lumix DMC-G85, and Nikon DL24-500, DL18-50 and DL24-85.

Wearable devices

Wearable devices include multi-purpose tools that use advanced sensing technologies such as voice command recognition, gesture recognition, and face and fingerprint recognition. OLED technology brings advantages of thinner and curved display form factor to wearable devices. Some of the wearable devices with OLED screens are Xiaomi Mi Band 2, MIO Slice, KIGO Watch, STARVR, Fitbit Alta, I Fit Vue, Mykronoz Zefit2 Pulse and Zefit2, Moto 360 Sport, Asus Zenwatch 2, HTC Vive, Sony PlayStation VR, Razer OSVR, Garmin Vivosmart, and Huawei Talk band B1 and Talk band B2.

OLED light panels

OLED technology enables large-area light panels. OLED displays can be used to make flexible, transparent and colour-tunable light panels. OLED panels emit diffused light, which is very close to natural sunlight. OLED light panels from various companies include IKEA Vitsand, SKK Gooseneck, Ascend, Acuity Brands Olessence and Nomi, Workrite Ergonomics Natural OLED, Bernd Unrecht Adjust-S, Pugnale and Nylene Volker OLED Luminaire, and OTI Aerelight OLED. There are light panels available from LG, Philips, Osram and Konica Minolta too.

What branch of engineering should I opt for if I want to design and develop display technologies like LCD, LED, OLED & flexible display?

How to interface RFID with OLED display using Arduino UNO and also how the words can be printed based on set cursor