Researchers from Austin have fabricated a unique type of electrode for lithium-ion batteries to tackle electric vehicle challenges

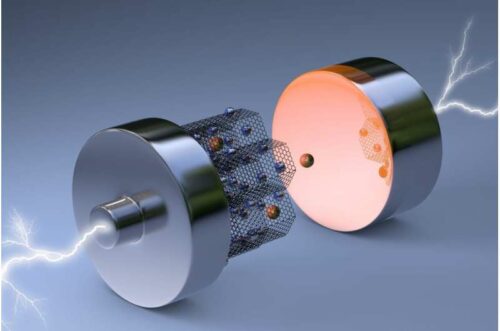

There is an increase in demand for electric vehicles due to the increase in fuel prices, but the major issue with using them is their limited range and slow recharging. To overcome this, researchers at the University of Texas at Austin have developed a new type of electrode for lithium-ion batteries that could provide greater power and faster charging. The team manufactured thick electrodes by implementing magnets to provide a unique alignment that circumvents common problems associated with sizing up these critical components. This results in an electrode that could easily provide twice the range on a single charge for an electric vehicle unlike a battery using an existing commercial electrode

“Two-dimensional materials are commonly believed as a promising candidate for high-rate energy storage applications because it only needs to be several nanometers thick for rapid charge transport,” said Guihua Yu, a professor at UT Austin’s Walker Department of Mechanical Engineering and Texas Materials Institute. “However, for thick-electrode-design-based next-generation, high-energy batteries, the stacking of nanosheets as building blocks can cause significant bottlenecks in charge transport, leading to difficulty in achieving both high energy and fast charging.”

Researchers used thin two-dimensional materials as building blocks of the electrode, arranged them to create thickness, and then used a magnetic field to manipulate their orientations. They used commercially available magnets during the fabrication process to stack the two-dimensional materials in a vertical alignment, creating a fast lane for ions to travel through the electrode. Also, to compare their electrode with a commercial electrode, they developed a horizontally arranged electrode using the same materials for experimental control purposes. They were able to recharge the vertical thick electrode to 50% energy level in 30 minutes, compared with 2 hours and 30 minutes with the horizontal electrode

“Our electrode shows superior electrochemical performance partially due to the high mechanical strength, high electrical conductivity, and facilitated lithium-ion transport thanks to the unique architecture we designed,” said Zhengyu Ju, a graduate student in Yu’s research group who is leading this project.

The researchers aim to generalize their methodology of vertically organized electrode layers to use it for different types of electrodes using other materials. This enables the technique to become more widely adopted in industry, so it could enable future fast-charging yet high-energy batteries that power electric vehicles.

Click here for the Published Research Paper