Green micro-supercapacitors produced from leaves could easily be applied to wearable electronics, smart houses and IoTs

Innovations in microelectronics and flexible electronics, especially energy storage devices have led to improvements in wearables having higher power density, longer lifetime and shorter charging time.

However, the challenge remains with respect to the safe collection, recycling and processing of waste batteries, caused due to the increased use of electronic equipment and their shortened replacement cycle. Another challenge persists regarding the neglect of fallen leaves from huge forest covers around the world. This inefficient disposal can contribute to forest fires, air pollution or global warming, endangering the flora and fauna inhabiting the forest.

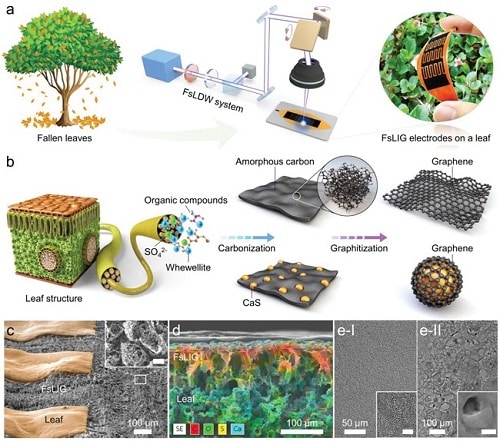

To solve both problems at once, a research team from the Korea Advanced Institute of Science and Technology (KAIST) in collaboration with the Korea Institute of Energy Research has developed a technology that can create porous 3D graphene microelectrodes with high electrical conductivity by irradiating femtosecond laser pulses on the surface of the leaves without additional materials. The researchers found this strategy to be applicable for developing new electronic components and thus came up with hybrid micro-supercapacitors.

The technique can power LEDs and electronic watches, opening possibilities for the mass production of low-cost flexible and green graphene-based electronic devices.

“Leaves create forest biomass that comes in unmanageable quantities, so using them for next-generation energy storage devices makes it possible for us to reuse waste resources, thereby establishing a virtuous cycle,” said Young-Jin Kim, professor at the Department of Mechanical Engineering, KAIST.