An electric distribution board connects all points of an electric system, and is also responsible for safety, signalling and circuit control. Considering all these necessary functions, a control cabinet should be fitted with high-quality equipment. A neatly designed cabinet, constructed in line with the best practices, is an electric engineer’s showpiece and, simultaneously, guarantees full users’ safety.

Electric Cabinet Components – Tasks

All incoming and outgoing electric cables installed in the distribution board close the current flow in a complete circuit, as they are routed through the equipment inside the cabinet. This is the first function of the distribution board, i.e. it divides the previously designed zones into separate electric circuits. Why is it so important? The answer to this question is quite simple, and we will discuss it using an example of a single-family house. The first and one of the most important reasons for this is the ability to separate an illumination circuit from, for example, electric sockets. When a lamp needs replacing, we deactivate the electric circuit associated with the illumination system in a room, thanks to which we can use a drill connected to a socket that remains operational. Additionally, if the rest of the house runs on a separate circuit, the occupants are not forced to sit in the dark, as the illumination system is fully operational there.

Distribution boards also fulfil the metering function. It does not only involve simple measurements of electricity consumed, but also operates smart energy management features available in more advanced solutions, as well as facilitates remote monitoring or control of the entire electric system, based on various parameters.

A distribution board also comes equipped with components that signal the presence (or lack) of voltage in a given circuit. These components usually communicate with users via indicators using different colour codes to signal various states.

Finally, we must mention the most recognisable distribution board feature, namely, the protection function. Everybody knows the importance of components protecting users against an electric shock possibly resulting from a short-circuit in an electric system. They are responsible for protecting human life and health as well as property, as a short-circuit can result in an electric shock or fire. Short-circuit, overload or overvoltage protections account for a large part of all components installed in the distribution board.

The importance of control gear should also be noted. It facilitates automatic control of electricity consumers by, for example, temporarily switching on or off their power supply, controlling dusk illumination sensors or managing the current flow intensity.

All of these functions are performed by various devices enclosed in an electric cabinet. Correct operation of the entire system usually depends on their quality, precision and reliability.

Modular Equipment – Types And Applications

Modular equipment includes devices designed as cubical modules with standardised dimensions, which fulfil various functions in an electric system. Identical mounting dimensions facilitate their installation on DIN rails. A significant advantage of introducing identical guidelines for all modular equipment solutions consists in the fact that even components provided by several different manufacturers are compatible with one another and can be used to create an operational system. Such features as incredibly easy assembly and disassembly, as well as independence from other, separated distribution board components, facilitate their modifications and replacements.

1) Residual current circuit breakers are among the most important and indispensable components enclosed in each electric box. Their principle of operation consists in deactivating the power supply when “differential current”, i.e. voltage, is detected on an electric device enclosure. It usually happens following damage to an electric system resulting from insulation failure and transmission of voltage onto the metal enclosure components. In such circumstances, an imminent risk of electrocution or fire occurs. To prevent these, the device detects the current intensity difference between the phase conductor and the neutral conductor, and cuts off the voltage supply to the system.

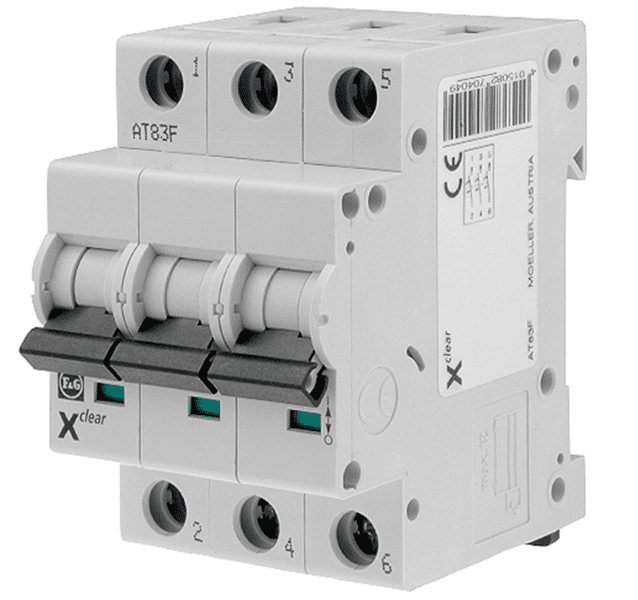

2) Overcurrent circuit breakers protect systems against the adverse effects of a current flow whose intensity exceeds the permissible value. This protection element also trips during short-circuits, thus triggering an automatic power cut-off. The main characteristics of overcurrent circuit breakers include such parameters as the number of overcurrent circuits and poles, or the rated current. The time-current characteristic of a circuit breaker is extremely important, as it determines the time and current at which the protection feature should cause the power supply to be deactivated.

3) Motor breakers, commonly known as thermal overload relays, are tasked with protecting electric motors. Such protection devices are typically used in workshops or industrial facilities where large electric motors are operated. The instantly cut off supply voltage, once a short-circuit, overload or phase failure occurs. Motor circuit breaker ensure safe machinery start-up, as well as convenient motor operation control and monitoring.

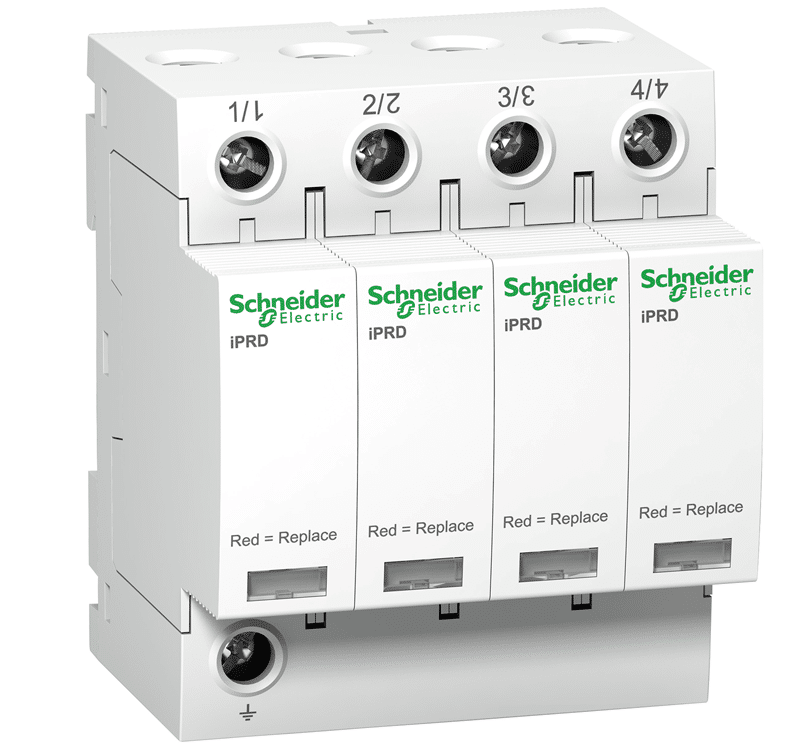

Surge arrester, type 2+3

4) Surge arresters are components that are vital to ensure the safety of electric devices connected to the mains. They are commonly known as lightning arresters, and they are designed with a view to limiting the mains voltage and stabilise it at a level that is safe for consumers. A proper module protects devices from the effects of voltage surges caused by a nearby lightning strike. Sophisticated electronic equipment is usually highly sensitive to overvoltage, so even minor fluctuations can affect its operation. Surge arresters are designed to protect it against any adverse impact.

5) Switch disconnectors are designed to disconnect power supply in industrial-grade control cabinets. They are usually installed on a cabinet enclosure to facilitate cutting off the current supply without opening it. Due to the fact that they frequently operate in adverse environmental conditions, such disconnectors feature a high IP rating, and are located within the operator’s sight. It is particularly important in emergencies when an instant response is required.