The robust contactless sensors are magnetic and can measure a range of physical quantities for IoT applications

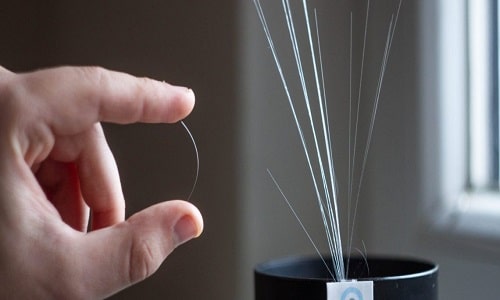

MicroWire sensors by RVmagnetics are miniaturised (diameter ca. 3–70 µm) magnetic contactless sensors of physical quantities (temperature, pressure, pull, mechanical stress, torsion, magnetic field, position, etc.).

MicroWires are made of metallic alloy core (diameter ca. 1–50 µm) and glass coating (thickness 2–20 µm). They are prepared by drawing and rapid quenching of molten alloys and glass.

Their size, high added value, robustness, simple production process and also their symmetry, glass-coating, possibility of contactless sensing leads to their utilisation as a miniaturised sensor with a wide range of applications in different industries: IoT, Industry 4.0, Structural Health Monitoring, Automotive, Aerospace, Smart materials, Healthcare, Anticounterfeiting area, etc.

MicroWire sensors are magnetic. Magnetic properties are mainly given by magnetoelastic interaction of magnetic moments with a distribution of mechanical stresses induced during production. Axial mechanical stresses arise as a result of drawing and rapid quenching of the wire. Radial and circular stresses arise from different thermal expansions coefficients of glass coating and metallic core. In addition, shape anisotropy is given by physical dimensions (diameter of the wire ∼1–40 μm, length of the wire ∼1–4 cm).

To sense the magnetic energy, an AC magnetic field needs to be generated with an excitation coil. Unless present in noisy magnetic or electric fields, the coil is powered with a few milliAmperes. The magnetic response from the MicroWires (with high sensitivity to temperature, pressure and position in the magnetic field), in terms of a magnetisation change, is sensed with another pick up/sensing coil.

Output from the sensing coil includes signals from magnetic and electric noises present in the vicinity of the sensing coil during the measurements. Filtered and amplified signal is digitalised in MCU (ARM chip) and ready for data post-processing in customer’s preferred software.