Autosilicon’s BDIC redefines battery technology by outperforming traditional EIS equipment, providing heightened accuracy while consolidating multiple functions into a single chip.

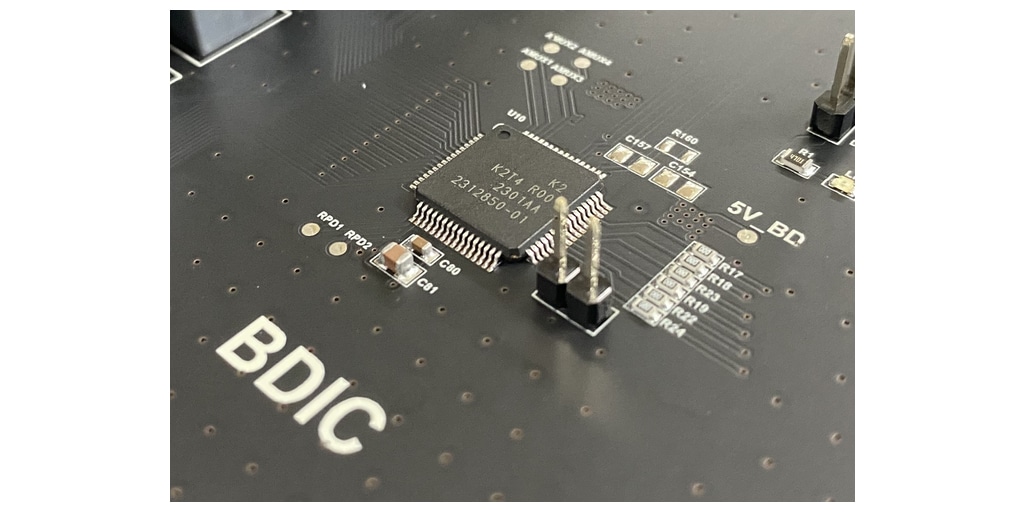

Autosilicon has launched the world’s first 14-channel Battery Diagnosis IC (BDIC) for Electric Vehicles (EV) and Energy Storage Systems (ESS). The primary role of BDIC is to gauge the Electrochemical AC Impedance of battery cells. This impedance, frequency-dependent and indicative of the battery’s condition, offers precise insights into the battery’s internal state. Unlike the traditionally used expensive and space-consuming Electrochemical Impedance Spectroscopy (EIS) equipment, BDIC significantly enhances measurement accuracy, operating current, and compactness. It outperforms EIS equipment and can even replace multiple such devices with just one chip.

A single BDIC unit accommodates impedance measurement for up to 14 cells, providing valuable data for battery cell diagnosis, prediction, and quality assessment, including State of Health (SoH) and remaining useful lifetime (RUL). Additionally, BDIC’s capabilities extend to battery modules and pack units. The company claims to develop an innovative algorithm and software that enables BDIC to measure the internal temperature of individual cells without external temperature sensors, enabling the detection of hotspots before potential fire or explosion incidents.

Beyond this, BDIC elevates the battery diagnosis function of existing Battery Management Systems (BMS) and lays the groundwork for battery cell grading required for recycling waste batteries. When combined with BMIC, BDIC offers advanced diagnostic capabilities and performance for xEV/ESS implementation, applicable across diverse battery diagnostic fields and Battery-as-a-Service (BaaS) ventures. The rollout strategy involves introducing 16, 18, and 24-channel BDICs by the close of 2023, a move poised to benefit domestic and international customers alike.

For more information, click here.