Traditional sensors have long held sway due to their established reliability and cost-efficiency. Yet, as technological demands advance, the distinctive attributes of printed sensors—namely, their flexibility and multifunctionality—take centre stage.

From their ability to seamlessly integrate into everyday objects like cars and healthcare devices, enhancing user experience with touch-sensitive controls and advanced security measures, to their role in pushing the boundaries of what is possible in electronics, sensors are more than just components—they are catalysts for change. Let’s dive into their versatility, the latest breakthroughs in materials, the hurdles they face in widespread adoption, and the exciting possibilities they hold for shaping the future of technology.

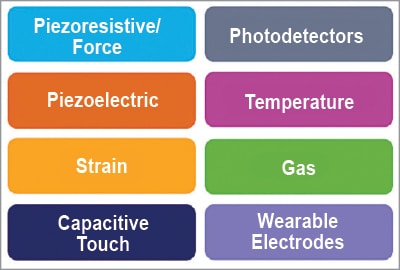

Sensors play a crucial role in blending our physical surroundings with digital capabilities, fundamentally altering how we interact with our devices. Printed and flexible sensors distinguish themselves through innovative deposition techniques on materials like plastics and silicones. They excel in scalability, covering expansive areas while maintaining sleek profiles, and offering multifaceted functionalities such as temperature and pressure monitoring. Their adaptability extends to detecting diverse parameters like force, touch, light, gases, and biometrics. For instance, a pressure sensor might utilise conductive carbon ink to measure force accurately. These cutting-edge sensors are poised to revolutionise large surfaces, potentially reimagining environments such as automotive interiors with seamlessly integrated touch and heating functionalities.

Driving growth: Material science for sensors

Material science advancements are pivotal in enhancing the capabilities of printed sensors. By developing new materials with improved conductive properties, sensitivity, and durability, researchers can create sensors that operate more efficiently and reliably under various conditions. These advancements enable the detection of a broader range of stimuli, crucial in complex IoT systems where multiple environmental factors need monitoring simultaneously.

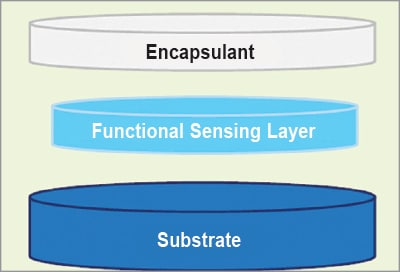

Printed and flexible sensors use a variety of materials to maximise performance. Epoxy and silicones provide adhesion and act as barrier layers, complemented by metals, polymers such as polyimide, polyethylene naphthalate, polyethylene terephthalate, dielectric elastomers, inorganic compounds, ceramics, nanomaterials, and composites. These materials impart flexibility and durability, supporting various sensor applications. Specific components like carbon-based inks, electroactive polymers, and conductive metallic inks or carbon nanotubes fulfil distinct functions in pressure, strain, and touch sensors, while innovations like quantum dots in photodetectors broaden their capabilities.

These sensors are designed to be compatible with flexible substrates and easily conform to curved surfaces. Scalable manufacturing enables the production of large-scale, multifunctional layers, which are vital for creating compact, integrated devices. Despite their versatility and essential roles across automotive, healthcare, and consumer electronics sectors, high costs and technical complexities restrict their wider industrial adoption.

| Impact of early adoption challenges |

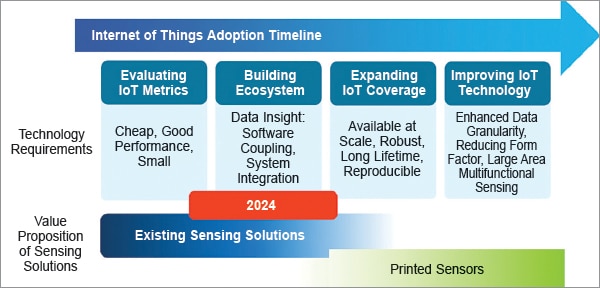

| From inception to broad use, the adoption timeline for printed sensors showcases technology progress and market readiness, highlighting a shift from niche to mainstream applications in sectors like IoT. • Traditional sensors are initially preferred in early IoT deployments for their proven reliability and cost-effectiveness. However, as demands evolve, the unique features of printed sensors—such as flexibility and multifunctionality—become increasingly vital, particularly for complex tasks like smart inventory management. • Printed sensors also enhance AI and AR technologies. For example, rubber sensors in AR gloves deliver precise hand movement data, enriching user interactions. Despite their advantages, the widespread adoption of printed sensors faces obstacles primarily due to the market’s preference for established, cost-effective solutions and the ongoing need to demonstrate their reliability and cost-effectiveness. |

Economic puzzle: Balancing revenue and costs

Printed sensors offer groundbreaking potential by integrating sensing capabilities onto flexible, large-scale substrates through advanced printing techniques. However, their market revenue remains limited, representing just a fraction of the multi-billion dollar global sensor market, indicating untapped opportunities.

Printed sensors present a dual narrative in technological innovation, offering revolutionary functionalities but facing challenges due to high production costs and competition from traditional, lower-cost sensor technologies. Their success relies on cost reduction, production scaling, and niche establishment. While their revenue potential may grow with maturity and expansion into more applications, they currently struggle to compete with established, cost-effective sensor technologies.

Market research attributes the disparity in market capture of printed sensors to their high production costs and niche applications. Unlike traditional sensors, printed sensors have not achieved widespread adoption that could drive down costs through mass production, resulting in relatively limited revenue generation compared to the overall sensor market.

The production process of printed sensors involves specialised ink formulation, printing, and curing, distinct from the subtractive manufacturing used for traditional sensors. These steps contribute to higher initial costs due to the need for bespoke materials and formulations that aren’t yet commoditised. For instance, while some printed pressure sensors use conductive carbon inks and are relatively inexpensive, emerging materials for other sensor types, such as photodetectors and capacitive touch sensors, remain costly due to their specialised nature and limited production scale.

Manufacturing advancements and navigating technical hurdles

Printed sensors are emerging as a transformative technology in the ever-expanding Internet of Things (IoT). These sensors seamlessly integrate with edge computing and AI to enhance device functionality, offering expansive coverage for applications such as autonomous driving. Their flexibility allows for integration into complex structures, and their cost-effectiveness supports scalable deployments.

Printed sensors are increasingly vital in the automotive industry. They enhance monitoring systems through edge computing for real-time data processing. This is particularly important for managing the battery health of electric vehicles, enhancing safety, and preventing failures. While mass production of these sensors is currently feasible, advancements in manufacturing, such as roll-to-roll and 3D printing, could improve scalability and reduce costs.

Incorporating printed sensors into IoT systems poses challenges, including competition with traditional sensors, but they offer substantial benefits in industrial IoT applications like predictive maintenance, asset tracking, and process optimisation. For example, printed piezoelectric force sensors can detect early equipment failures by monitoring vibrations. However, the deployment of printed sensors raises significant security and privacy issues, necessitating robust encryption and secure communication protocols to safeguard against cyber threats, especially in critical infrastructure.

Despite their advantages, printed sensors face considerable technical challenges in automotive systems, including integration with existing technologies and issues with reliability and durability. Rigorous optimisation of the printing process is necessary to achieve consistent performance. Continuous advancements in material science and manufacturing are crucial to addressing these challenges. Additionally, technical and security challenges must be overcome for the widespread adoption and success of these technologies in the IoT landscape. As industries innovate, the role of printed sensors is expected to expand, further driving advancements and opening new opportunities.

Sensitivity

Loss occurs because the printing process can reduce the effectiveness of the active sensing material.

Sensor drift

Deviation from baseline measurements is particularly problematic in applications where the sensor undergoes repeated deformations, such as in printed pressure sensors.

The flexibility of the sensors, while beneficial, can affect their reliability and the robustness of the sensor materials. Despite these advantages, printed sensors in IoT still face significant hurdles. The primary challenge is the technology’s maturity and reliability compared to conventional sensors, often due to their proven performance and lower cost in standard applications. Additionally, while printed sensors offer multifunctionality, this feature is not always necessary for certain IoT applications, where simpler, dedicated sensors may suffice.

Encapsulation issues intensify printed sensors’ challenges, where protective coatings may degrade, impacting performance. Innovations in sensor architecture and materials are underway to overcome these limitations, including designing more robust functional layers and improving ink formulations for better durability under stress. Enhancements in encapsulation technologies are also being made to protect sensors from environmental degradation.

To address these obstacles, companies focus on integrating printed sensors into broader applications, such as combining temperature and pressure sensors in a single module for electric vehicle battery monitoring. This integrated approach aims to enhance the appeal to OEMs and end-users, showcasing printed sensors’ unique capabilities and improving market alignment.

Driving the future

Printed sensors are emerging as a critical innovation in the automotive sector, reshaping how vehicles are experienced and operated. Here are the key highlights:

Interactive interior surfaces

Integrating conformal printed capacitive touch sensors transforms vehicle interiors into interactive hubs. These sensors allow drivers to control infotainment systems through simple touches or gestures, such as adjusting the volume or navigating menus.

Enhanced security with biometrics

Printed sensors enhance vehicle security by incorporating biometric fingerprint authentication. This technology, situated under display screens, authenticates drivers and provides personalised access, reducing the need for traditional keys.

Support for electric vehicles (EVs)

Printed sensors are pivotal in developing advanced thermal management solutions essential for maintaining battery efficiency and vehicle performance. They contribute to reducing overall vehicle weight, further enhancing EVs’ performance and range.

Advanced driver-assistance systems (ADAS)

Integration with transparent conductive films in ADAS sensors boosts vehicle autonomy by improving passenger-vehicle interactions and enhancing safety features.

Comfort and safety innovations

Seat occupancy detection uses printed force sensors integrated with heaters to guarantee safety and comfort by accurately detecting if a seat is occupied. The sensors assess various factors such as strain, gas, pressure, and temperature to ensure the batteries operate efficiently and last longer.

Beyond individual vehicle enhancements, printed sensors offer a significant advantage in market differentiation. In an industry where many vehicles possess similar features, these sensors allow automakers to distinguish their products by offering advanced, personalised features that meet evolving consumer expectations. This innovation enhances vehicle functionality and plays a strategic role in positioning products in a competitive market. Printed sensors are setting the stage for the future of the automotive industry, emphasising safety, efficiency, and user experience. Their role is expected to expand as they continue to drive innovation in electric vehicles and beyond.

Regulating innovation: The impact of safety standards

Regulatory standards and safety certifications are critical for the Internet of Things (IoT) and automotive technologies. They shape the development and deployment of technologies like printed sensors, ensuring safety and performance. In automotive applications, such as battery health monitoring in electric vehicles, regulations dictate the level of detail required for monitoring to enhance safety and prevent failures, influencing the adoption of sensor technologies.

Safety certifications are crucial for integrating new sensor technologies in the automotive industry. Sensors in battery monitoring systems must detect and manage failures safely, which impacts sensor design and functionality. Despite their potential, printed sensors face challenges in reliability and durability in automotive settings. Material science and sensor design improvements are necessary to address these issues.

Printed sensors also contribute to autonomous driving and vehicle connectivity, enhancing user interaction by integrating into large-area interfaces and enabling biometric data detection within car interiors, which could transform passenger experiences. The widespread use of printed sensors across various sectors, such as IoT, automotive, and consumer electronics, brings significant ethical and societal challenges. These include environmental concerns, privacy issues, data security, and socio-economic disparities.

Environmental impact

Printed sensors often contain non-recyclable plastics and conductive inks, leading to potential increases in electronic waste. This issue necessitates the development of sustainable manufacturing and disposal strategies to minimise their environmental footprint.

Privacy and data security

As sensors become more integrated into daily life, the risk of personal data misuse grows. Implementing robust cybersecurity measures, including strong encryption and secure data handling protocols, is crucial to protect user privacy.

Socio-economic disparities

The uneven availability of advanced technologies can exacerbate the digital divide between high-income and low-income regions. Promoting equitable access to sensor technologies is essential to mitigate these disparities and support inclusive growth.

Consumer education and market penetration

Educating consumers about the capabilities and limitations of sensor technologies is vital for setting realistic expectations and encouraging acceptance. Effective distribution strategies are also necessary to maximise market penetration and the overall impact of these technologies.

| Market on the rise: Innovation fuels expansion across key industries |

| The market for printed sensors is projected to expand at a CAGR of 8.6%, reaching approximately $960 million by 2034, with printed piezoresistive sensors driving most of the revenue growth. These sensors have demonstrated significant versatility and impact across various industries, such as: • Automotive applications enhance safety through seat occupancy detection and seatbelt sensing • Smart buildings effectively prevent water leak damage by wrapping around plumbing and detecting leaks at the source • Healthcare printed sensors are used for dental bite analysis and gait monitoring and were once dominant in glucose testing for diabetes Despite challenges from low-cost alternatives in smart agriculture, printed sensors are evolving to monitor soil moisture, pH, and nutrients more effectively, with potential advancements in shortwave IR sensing for crop health. Overall, these sensors promise to revolutionise traditional practices with technological innovation. |

Strategies for tech integration partnerships

Collaborations among automakers, sensor tech companies, and material suppliers are key for integrating printed sensors into vehicles, ensuring compliance with regulatory standards and delivering advantages over traditional sensors. The competition with traditional sensors is intense, challenged by scalability and mass production costs. Strategies such as showcasing at trade shows, developing demo products, and strategic design partnerships are crucial to carving niche markets.

Government support through initiatives and funding is vital for advancing printed sensor technology, especially in the R&D stages. As sectors like IoT and smart manufacturing grow, printed sensors are expected to see significant application expansion, enhancing functionality and user interaction. However, overcoming technical, ethical, and market challenges is necessary for their full potential realisation.

Printed and flexible sensors represent a significant development in merging the digital and physical worlds, offering advanced interaction through their ability to be deposited on various substrates. These sensors promise to revolutionise user interfaces across automotive, healthcare, and consumer electronics by integrating multiple functions like temperature, pressure, and touch on large, flexible surfaces. However, challenges such as high production costs, technical complexities, and competition with traditional sensors limit their market adoption. Addressing these barriers through advancements in material science and manufacturing, along with navigating regulatory, environmental, and ethical concerns, is essential for their successful deployment. As these technologies evolve, printed sensors are set to transform industry norms and enhance our interaction with technological systems, making large interactive surfaces a reality.

Akanksha Sondhi Gaur is a journalist at EFY. She has a German patent and brings a robust blend of 7 years of industrial & academic prowess to the table. Passionate about electronics, she has penned numerous research papers showcasing her expertise and keen insight.