Portable power stations (PPS) are a new breed of products that allow significant energy storage at the user end and also allow for its use in either AC or DC form. The PPS come in various shapes and sizes, from the small ones giving about 50Wh of energy to larger stations of up to 4kWh capacity

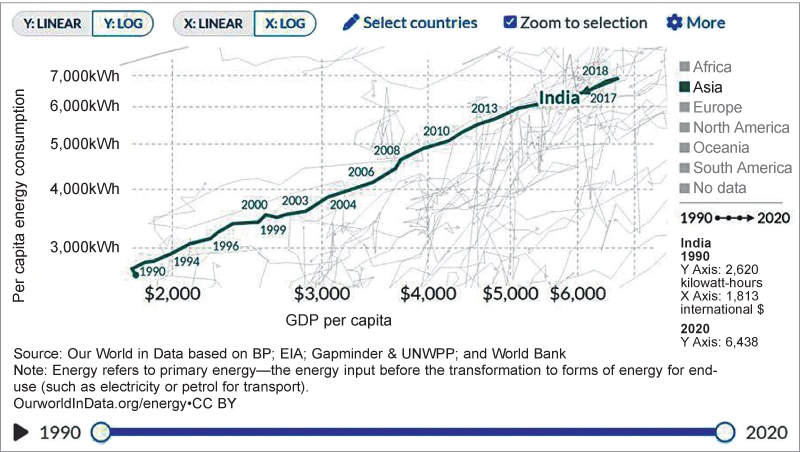

The difference between developed and emerging economies is generally expressed in terms of their per capita purchasing power parity or the per capita GDP. Another interesting data that can be considered is their per capita energy usage. Based on the freely available ample data that we have now, as shown in Fig. 1, it is clear that there has been a strong correlation between these two quantities.

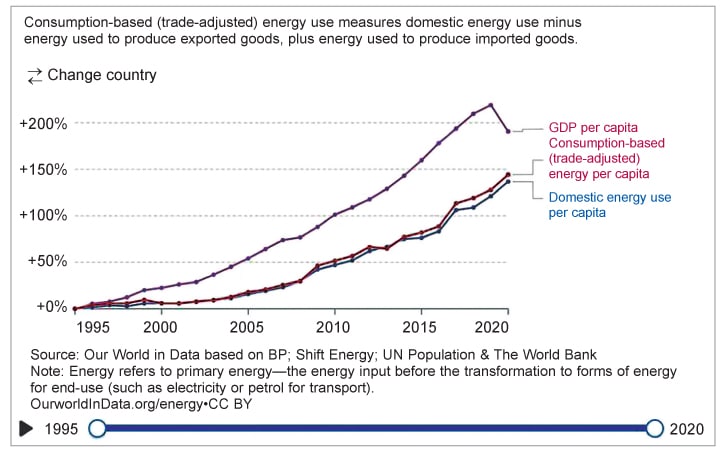

Also, interestingly, not only the actual values but the changes in these two quantities are also strongly correlated, as shown in Fig. 2—particularly for emerging economies. This suggests that the economic development of a developing country corresponds to its per capita energy usage. So, a postulation as a corollary to the above data is that increasing the per capita energy use can result in increasing per capita GDP of the country!

Energy usage is distributed across different sources and one of the important forms of energy is electrical energy. To be able to use electrical energy, its stable availability is imperative. Over the years, it has been found that large-scale power production is sustainable in the long run. However, this produced power needs to be transmitted immediately to loads scattered across the grid. In fact, power production is usually kept in sync with the ongoing power demand on the grid.

But large scale energy storage is not so sustainable. Apart from operational challenges in large scale energy storage, one of the important factors is that most storage mechanisms use the direct current (DC) form, whereas the production of power and its transmission is mostly in the alternating current (AC) form.

There are inefficiencies in the conversion from AC (sources) to DC (storage) and back to AC for transmission, which compound to make this a bad choice. More so because the eventual personal usage of energy is mostly done in the DC form. Hence, looking at various aspects, decentralised energy storage systems become very important.

Portable power stations (PPS) are a new breed of products that allow significant energy storage at the user end and also allow for its use in either AC or DC form. The PPS comes in various shapes and sizes, from the small ones giving about 50Wh of energy to larger stations of up to 4kWh capacity, which provides on-demand energy at customer establishments to run various appliances for a significant time.

Being an energy storage equipment, it obviously comes with the relevant battery storage and battery management systems. The PPS, however, also come with special capabilities which differentiate them from simpler equipment, such as portable power banks. These have the following abilities:

- Provide both AC and DC forms of power and sometimes at multiple voltages.

- Can get charged from multiple sources (in some cases simultaneously), such as the grid AC supply or via direct DC inputs like solar PV or in-vehicle 12V supplies.

- Can be paralleled to provide for on-demand larger storage capabilities.

In addition to their ability to provide user-end on-demand energy, these systems can also play a pivotal role in times of natural disasters. As we all know, the first things to go out when a storm hits your neighborhood is the electrical supply. In such times, a PPS can be a lifesaver, as it can run most of your home equipment for a long time. PPS units can also be lifesavers on long trips, off-roading adventures, and other places, such as family picnics and camping.

As electrical vehicles become more common, PPS units can be treated as your reserve fuel, as they can charge the EV through their AC outlets. Those from an earlier generation may remember portable generators, which could be used to provide on-demand power in shops, markets, homes, etc. All such use cases apply directly to portable power stations.

For the benefit of all, let’s try to figure out what goes into making a portable power station. As the name suggests, a PPS is a storehouse of energy that can provide significant amounts of power through its various different output ports and can be charged up from various sources of electrical energy.

Some of the well-known brands of PPS in the USA are:

1. Jackery

2. EcoFlow

3. Bluetti

4. Anker

5. Pecron

Solar product suppliers in India also provide variations of PPS that are sometimes called solar generators, solar home UPS, or solar backup home lighting systems. Most of these are stationary systems installed in homes and offices and used mostly for lighting purposes. The aspect of portability while providing a significant power output is rarely available and presents a Blue Ocean market situation for Indian manufacturers.

Besides, while there are multiple solar home lighting system suppliers in India, their products often look and feel similar, which suggests that these products are assembled from commonly available parts and not manufactured by the supplier. The actual look and feel of a product play a big role in forming a connection with the customer and this aspect should be considered by the manufacturers.

In addition, many white goods brands also produce PPS. The above US brands have been able to make a name for themselves by providing a number of choices to the customers so that products that suit their exact needs are made available to them. Examples of these products are shown in Fig. 3.

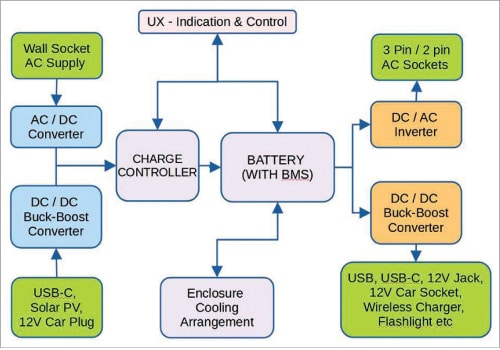

As shown in Fig. 4, a PPS consists of mainly the following:

- AC-DC converters

- DC-DC converters connected to DC inputs

- Multiple input charge controller

- Battery source with a BMS

- DC-DC converters connected to various DC output ports (USB-C, USB, 12V car socket, wireless charging ports)

- DC-AC inverters produce stable and pure sine wave AC output at their various ports

In Fig. 4, all the major elements of a typical PPS have been shown. The input and output ports are shown in light-green boxes, input electronics in light blue, output electronics in amber, and the battery and its related electronics have been shown in the light-purple background. The design of the unit has the following important features:

- Input-output ports

- Battery and BMS

- Enclosure

- Indication and control

- Power conversion

Fig. 4: A block diagram view of a typical portable power station

Input-output Ports

The first and foremost design aspects are the type of input and output ports the product should have. Any decent power station should have enough input and output ports to be able to support multiple charging and discharging devices.

Input ports: A typical input port is the 3-pin AC wall socket. Since portability of the unit is important, it would be good to have a removable AC power cord, which connects to a 3-pin AC input port on the PPS. Better still would be a retractable AC input cord that folds into the unit for easily carrying the same with the unit.

Since the power station may be used away from home/office, it would be great if it could be charged using a solar PV input. The typical 12V input socket from a solar PV panel is a good candidate in this case. Sometimes, the PPS may need to charge from another PPS; in this case, there should be a way to charge using a direct DC connection between the two PPS units.

Output ports: Output ports may also be the regular 3-pin and 2-pin AC sockets. These would require a good quality inverter—if possible, a 3-phase 220V AC inverter. This is important because some items may require 120V AC (which can be provided by using a phase and the neutral), and some may require 220V AC (which can be provided across two phases).

While such AC sources are used in homes and offices, one has to remember that unless the PPS unit is connected to the main grid neutral at all times, the AC outputs produced by the PPS will not be ground referred. Therefore, typical earth leakage/fault protection mechanisms (such as residual current breakers) made mandatory in home wirings will not be possible for these AC sources. The PPS may allow the user to connect the true earth ground to the PPS using a special ground terminal, and in this case, the PPS must provide the above protections on all its AC outputs.

Typical DC output ports will constitute USB-A ports, USB-C PD ports, 12V jacks, and 12V car charger sockets. A USB-A port may be created by using a simple 5V buck converter of the required current capacity. A special power delivery (PD) USB-C adaptor will be required for the USB-C ports. Car charger sockets can provide up to 4A current, so the 12V buck adaptor used by the PPS must provide that current.

Some PPS units provide an ambient light source with brightness level controls. These are great for outdoor use and use as an emergency lights during power cuts.

As wireless charging of smartphones comes of age and becomes more common, many of the PPS makers would need to provide at least one, and sometimes two, wireless chargers integrated into the PPS. This is a big feature for the consumers who opt for wireless charging of their phones, and would definitely be a great addition to the PPS feature lists. Although, this feature would also increase the cost of the unit quite a bit.

Enclosure

The enclosure plays an extremely important role in the success of the PPS units. As shown in Fig. 3, the enclosures of the most well-known brands are made of high-quality plastic, which seems to be slightly against logic, as heat removal is best done in a metallic enclosure.

However, modern plastics can provide good enough heat removal capabilities (UL94 V-0 type plastics), while ensuring that the user experience is great as far as look and feel is concerned.

As in all other products, enclosure design is an integral part of the product design. In addition to important facia details, such as the location and size of the indication and control apparatus, location of the input and output ports, and many minute details—such as the location of the carrying handle, path for the air passage, location of forced cooling fans, presence of an ambient light source—have a huge impact on the overall customer experience. As the energy capacity of the PPS grows, the enclosure needs to incorporate metallic parts and even drawing wheels to ease the portability of the units.

An important aspect of enclosures would be to ensure that there is enough free space left for a clear air circulation path. This space could be calculated from the worst-case power dissipation values (in watts), which would give an idea of the temperature rise that may happen in locked stationary air and then deducing the amount of air to be displaced per unit time, which will lead to the sizing of the free air space and the fans used for forced cooling.

Indication and Control

Most modern-day systems have some kind of screen to show their status and to allow the user to make control selections. Although there are not much control selections that the user can make in a PPS, it has been a convention in almost all PPS units to have an LCD or a TFT screen which provides detailed status information about the unit. The typical items shown on the screens are:

- Battery charge indication in the percentage of the overall Wh capacity

- Battery charging and discharging indication

- Time of complete discharge to show how long the PPS unit’s battery will last at the present discharge current levels

- Time to full charge to show how long it would take for the PPS battery to be fully charged at the present charging current level

- Charging input levels for each type of charging input

- Discharging source indication and level of discharge for each

The typical control selections are starting and stopping of different discharge sources, such as AC and DC output switches.

Power Conversion

The power conversion components form the heart of the entire product. As shown in Fig. 4, the power conversion architecture includes the charging controller, battery and BMS, AC to DC rectifiers, DC to AC inverter, and DC to DC converters at both input and output ports.

There are multiple product teardown videos online, and most of these videos show that the PPS units have purpose-built PCBs, which provide the most efficiency and integration of all capabilities that the PPS offers. This often means that the designers would need to create PCBs that could be used in multiple products, with specific hooks to select specific capabilities based on the product model. This integration also aids in the maintenance and repairs of PPS units and reduces e-waste as there are fewer PCBs to recycle.

Some PPS units also allow multiple units to be chained (chainable units) with other similar units to provide longer backups or higher power. This capability should be easy to implement as long as the BMS in both units can talk to each other over side-band connections provided in special chaining cables. Such chaining would put the batteries inside the PPS units in parallel.

While prevalent in the discharging mode, we are yet to come across a chainable PPS that allows chained charging of multiple units from a single source. This may be because charging times are reduced when they are charged individually.

There are numerous possibilities in this space. Beyond the civilian use cases, PPS units may be of help in defense and paramilitary activities as these activities require active use of electrical power at places where the electricity grid may not be available.

Vishal Sapre is an electronics design professional working with Righill Electrics as GM (Technical). His interests include embedded control systems, IoT, power electronics, and the use of interpreted language systems, such as Python in microcontrollers