Why are testing and measurement of quantum chips necessary? The answer lies in OEMs unlocking breakthroughs in performance with this, using specialised tools and cryogenic precision for the future of quantum computing.

Testing and characterising quantum chips is essential for original equipment manufacturers (OEMs) to ensure their reliability and longevity. This process must occur at various stages, including research and development (R&D), quality control, and production line levels.

Quantum processors are constructed of units known as ‘quantum bits’ called ‘qubits’, which undergo a phenomenon called superposition. Unlike traditional data bits, qubits can represent both one and zero simultaneously. Multiple qubits can also demonstrate marvellous interactions called entanglement. Using these quantum behaviours in concert, qubit-based systems can evaluate, in parallel, enormous numbers of potential solutions to complex problems. However, qubits are extremely sensitive to small amounts of thermal noise. Therefore, they are kept at temperatures approaching absolute zero to maintain a stable state long enough to complete their calculation (‘coherence’). For further efficiency, designers often need superconducting connections to build qubits.

The leading edge

Quantum chips are based on superconductors and are fragile and prone to errors, typically from fabrication defects. Test and measurement methods are crucial to detecting the errors that compromise quantum calculations, but today’s lab-based approaches are slow. Testing a small chip in a cryogenic lab can take engineers several months to complete. Conventional chips typically can be tested in thousands in a few hours across an entire wafer.

IBM, Intel, Honeywell, and a host of startups are all working together to build highly integrated quantum processing units (QPUs) with the goal of packing more qubits into a small space. QPU is the future of the chip industry. Five-qubit quantum canary processor, 27-qubit quantum falcon processor, 65-qubit quantum hummingbird processor, and 1121-qubit quantum condor processor (developed in 2023) are some of the QPUs developed by International Business Machines Corporation (IBM). Intel recently used 300 nm wafers with the extreme ultraviolet (EUV) process to fabricate quantum dots and gate yield.

Technology supremacy

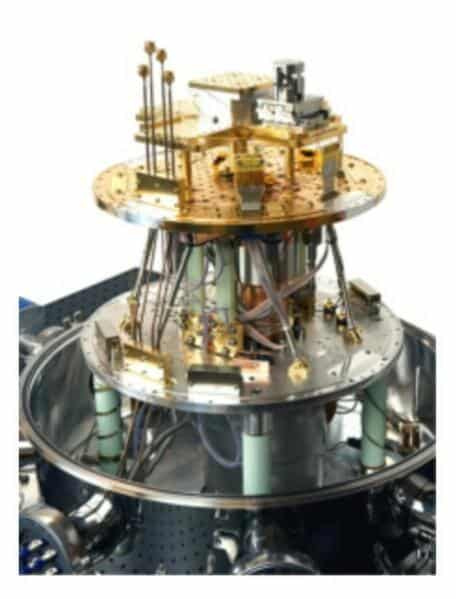

Quantum chip metrology is still in its just-born stage. Quantum chips grow in size as manufacturing moves from lab to fab. This is one of the main problems in today’s lab-based testing. Further, quantum chip testing requires high-vacuum conditions at cryogenic temperatures.

Let us take an example of a 100 qubit-scale quantum processor. First, it is cooled to milliKelvin (mK) temperatures. Key performance parameters, such as coherence and randomised benchmarking-based gate error rates, are checked during testing.

In the ‘squid-on-tip’ approach, a superconducting quantum interference device (SQUID), which detects weak magnetic fields and temperature gradients based on superconducting loops, is mounted onto the tip of an atomic force microscope and used to scan the quantum chip during development and manufacturing.

The system detects many parameters, including changes in local temperatures, leakage currents, stray radio frequency (RF) fields, and magnetic moments across the chip—all of which point to potential problems with chip quality.

A 100-qubit scale quantum chip would take about two and a half days. In addition to the cryogenic cycle, a complete cycle involving the insertion of the hecto-qubit quantum processor into the system, conducting tests, and subsequently retrieving it, is estimated to take about a week.

Quantum processor measurement and testing devices

Some of the T&M (test and measurement) devices for quantum chips are described below.

Adiabatic demagnetisation refrigerator (ADR) cryostats

It aims to support ultra-low temperature research by providing quick and affordable access to mK temperatures. Many customisable options make it easy to reconfigure to fit specific needs. A variety of ADR models are available to provide a range of sample volumes and cooling power.

These systems use a one- or two-stage ADR to reach temperatures as low as 30mK. ADR operates by submitting a salt crystal to magnetic fields. In these different states, the salt crystal will either absorb or dump thermal energy. This is used to shuttle heat away from the sample stage, achieving mK temperatures.

ADR cryostats are excellent substitutes for dilution refrigerators (DRs) due to rapid cooldown, ease of use, and solid-state reliability. They quickly pre-screen qubits and quantum processing units (QPUs) before their full DR test.

Cryogenic probe station

It is used for on-wafer and multi-chip measurements to support a wide range of challenging applications, including infrared (IR)–sensor tests, radiometric tests, direct current (DC) and RF measurements at cryogenic temperatures. Such a high-precision, fully automated probe station can inspect 150mm, 200mm or 300mm substrates in a 4K environment.

Ultra-low vibration chip- scale probe station

It helps to meet all your probing needs, emphasising ultra-low vibration applications. This system employs a range of thermal isolation techniques to take full advantage of all the cooling power available. All interfaces have been specially designed to block any radiation from disturbing the sample.

Qubit controller

The system features two, four, or six signal generator channels, along with one quantum analyser channel, offering operation at up to 8.5GHz with a 1GHz analysis bandwidth, free of mixer calibration. It provides low phase noise, minimal spurious tones, and high output power, enabling fast, high-fidelity gates. The real-time signal processing chain includes matched filters and multi-state discrimination for enhanced performance.

The qubit controller can be controlled via LabOne, LabOne Q, or application programming interfaces (APIs) for Python, ensuring flexibility in operation. It supports coherent control of qubits through single and multi-qubit gates and features dispersive single-shot readout. Additionally, it offers fast qubit and resonator spectroscopy, along with setup characterisation, making it adaptable for systems ranging from one or two qubits to over 100 qubits.

To sum up

Testing methodologies in quantum chips play a pivotal role in advancing the field of quantum computing. Through meticulous experimentation and analysis, researchers have illuminated key insights into quantum processors’ performance and behaviour, highlighting their capabilities and limitations.

These conclusions not only contribute to the ongoing refinement of quantum hardware but also inform future strategies for optimisation and scalability. Furthermore, they emphasise the importance of continued collaboration between theorists and experimentalists to address remaining challenges and unlock the full potential of quantum technologies.

Vinayak Ramachandra Adkoli holds a BE degree in Industrial Production and has been a lecturer in three different polytechnics for ten years. He is also a freelance writer and cartoonist.