The continuously-evolving technology, modification and creation of standards, and increasing requirements of customers are pushing the test and measurement equipment industry to move at a faster pace. All players in this domain, whether big or small, are striving to manufacture and supply devices that fulfil these criteria. Traditional stand-alone test equipment are usually heavy, need to be connected to the line, and often do not work well in rugged outdoors, hard-to-reach or moving environments. This has led to one notable trend in this segment—increasing demand for handheld devices, observes Naresh Narasimhan of Tektronix India.

The myth about handhelds

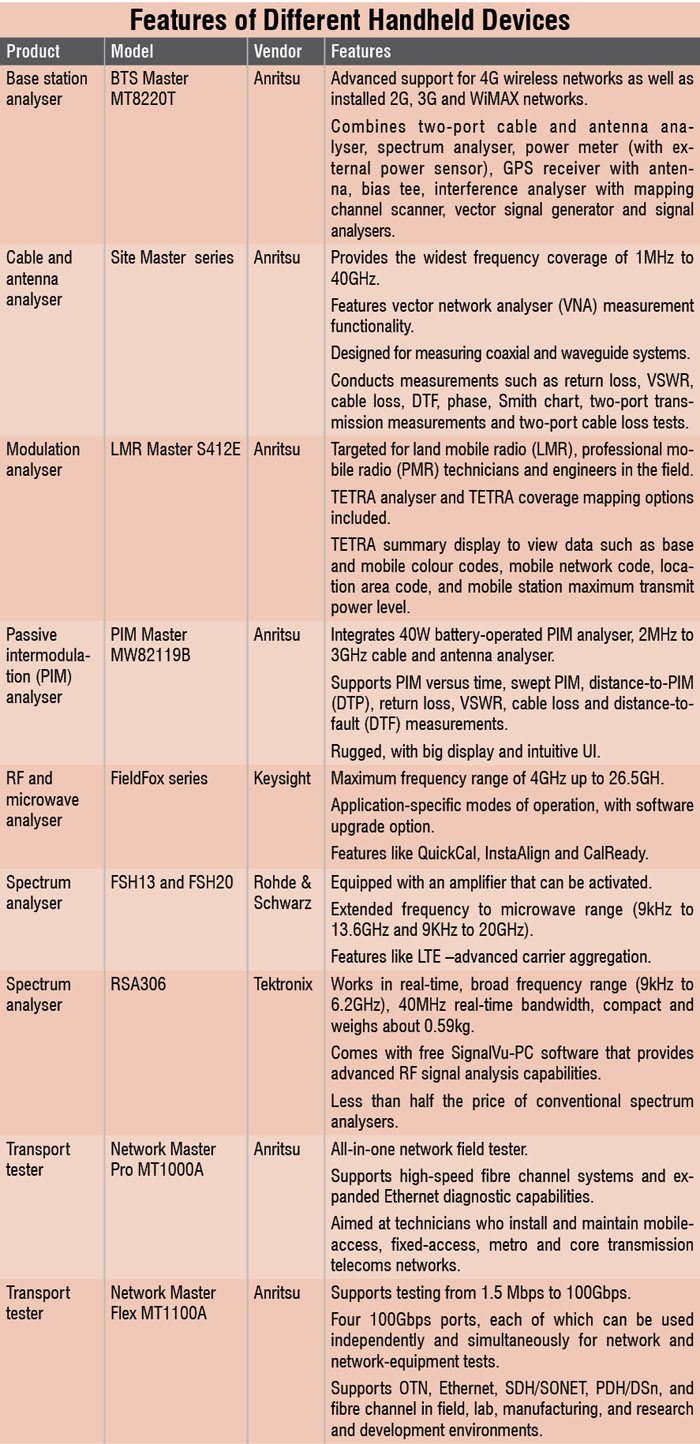

People often perceive handhelds to be inferior to benchtops in terms of functionality, performance, precision and accuracy. But, if you look at today’s test and measurement industry, many models available in the market offer very good performance as compared to benchtop instruments. “Now, a handheld instrument is featured with full specifications that are able to meet specific end-user application requirements,” says Madhukar Tripathi of Anritsu India. “They offer better cost-performance to buyers,” he adds.

When and why to use handhelds

There are three main scenarios where test and measurement is done on the field. The first is during installation, where technicians or engineers use the device to verify whether the system is up-and-running with the right frequency, voltage or such similar parameters. The second situation is during periodic, condition based or corrective maintenance of the system. This is where you need to assess the performance, recalibrate the system, identify and rectify the fault, and prevent possible issues that may come up. Third, it is used for system monitoring. An example is the monitoring of spectrum to check whether a band is available or not.

Handheld devices are mostly used in field applications because such cases require portability. The device should have battery-operation capability and the battery should provide enough backup. “High-accuracy and repeatability are desired, but not mandatory for field devices,” says Asish Jain of Keysight India, “because most field applications are a go/no-go test where the user wants to know whether the system is functioning or not.”

Where the industry is heading

Listed below are some general trends we find in the handheld test and measurement industry.

Improved measurement range. Electronics test and measurement instrument manufacturers have been trying to extend the range of measurement in a way that it can be used for more applications. But, with increased range of measurement, there comes an increased complexity of design. This should not compromise other features. Every component has to become smaller and more components have to be integrated without increasing the probability of leakages. Rohde and Schwarz (R&S) FSH handheld spectrum analyser series now offers a frequency range up to 20GHz, and Keysight FieldFox series RF and microwave analysers have models that cover a frequency range of about 26.5GHz, thereby covering most aerospace and defence applications.

Smaller size. Technologies like quad flat no-leads (QFN) packaging have helped reduce the size of individual components and, hence, the device as a whole. In this technology, integrated circuits (ICs) are mounted on PCB surfaces without leads or through-holes. Another method of size-reduction used in the radio frequency range is by using monolithic microwave ICs (MMICs) instead of discrete components for functions such as power amplification, microwave mixing, and low-noise and high-frequency switching. This not only reduces the size but also lowers the power consumption, thereby improving battery life. The new RSA306 spectrum analyser by Tektronix is as small as 3.05×19.05×12.7cm and weighs just about 0.59kg.

Integration of devices. Integrating multiple instruments into a single system is a major trend we now see across different verticals of the industry. Handhelds usually have several devices integrated into a single system with small form factor, and the cost is also much lower compared to benchtops. A single handheld instrument occupies very little space compared to benchtops. MW82119B PIM Master by Anritsu combines PIM and line-sweep testing capability in a single portable instrument.

When taking instruments to the field, we need other accessories like calibration kits. Some of these accessories are now integrated inside the system. QuickCal is a patented technology by Keysight that provides in-built calibration to a device. This reduces the number of accessories to be carried to the field. Another feature introduced by this firm is CalReady, where the unit is factory-calibrated and calibration-ready at test ports.