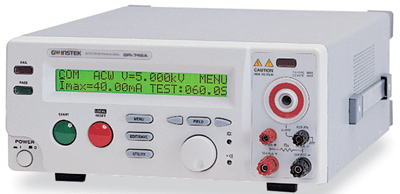

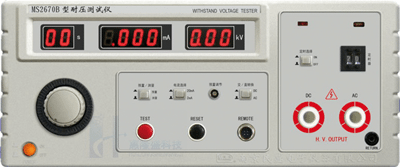

Electrical safety is of utmost importance for all the electrical and electronic products. Today’s HIPOT (short for high-potential) testers—key test equipment for electrical safety—have come a long way in terms of features, programmability and safety involved in testing itself

SHWETA DHADIWAL BAID

JULY 2010: Someone has rightly said that “Safety doesn’t happen by accident.” Today, most consumer electronics devices operate in close vicinity of the human body, be it a mobile phone, laptop, home appliance or medical device. Any product designed without electrical safety parameters in mind may result in a mishap. The finished product needs to be tested thoroughly before it is put in use. Several tests have to be conducted from design to production stage in order to ensure electrical safety of the component and the finished product.

No designer wants to design an unsafe product, but many a times the product may fail in operation due to some design flaw or faulty components. Electrical safety tests are performed on components such as transformers and switches, cables, motors and finished goods. Several standards organisations publish the permissible limit for different parameters. Organisations like CSA in Canada, UL/ETL in the United States, GS in Germany, EK in Korea, CCC in China and CNS in Taiwan provide electrical safety/international standards, shares Helena Wang, sales manager, GW Instek. In India, Indian Standards Institute (ISI) specifies electrical safety parameters for many products. Usually, manufacturers hire certified test labs to perform safety tests to comply with these standards and get their products certified.

Insulation plays an important role in electrical safety. During production, most manufacturers include tests around insulation in order to meet safety requirements as per specific standards. As opposed to continuity tests that ensure current flow, there are tests performed using high potential (HIPOT) to ensure that the current does not flow from one point to another at a given voltage for a given time.

Need for electrical safety tests

Electrical safety tests may be mandated by the standards’ organisations, but as a manufacturer, it is your social responsibility. Tests do consume some time in the production line, but these significantly reduce the risk of fires, accidents, electrical shocks, etc from the equipment. It is very important to test insulation as 80 per cent of electrical maintenance and testing involves evaluating insulation integrity.

Electrical insulation starts deteriorating in its performance as an insulator (extremely bad conductor) with time. The most important reason for testing insulation is to ensure public and personal safety. “Insulation testing is used to determine the integrity of windings or cables in motors, transformers switchgear and electrical installations,” shares Prachi Gupta, director, Avante Global. “By performing a high-potential test between de-energised current-carrying, grounded and grounding conductors, you can eliminate the possibility of having a life-threatening short-circuit or short-to-ground faults,” she adds.

Electrical and electronic systems when exposed to environmental factors such as dirt, grease, temperature, stress and vibration affect the dielectric material used in insulation. This may lead to insulation failure, resulting in loss of production or even fire. “It is important to identify the deterioration as early as possible to take corrective measures,” suggests Ms Wang.

HIPOT tests

When a high potential is applied between isolated parts of a circuit or a product, the behaviour of electrical parameters helps identify broken or poor insulation, stray wire strands or braided shielding, spacing problem between terminals, tolerance errors, etc. This helps in making informed decision on the safety and quality of electrical circuits.

“The value/range of HIPOT depends on the device under test (DUT),” shares Rohit Manwani, chief executive officer of Sunil Associates. “Range of the instrument varies from industry to industry. Some industries can accept the sample if insulation resistance is more than 1000 mega-ohms, while some look for values in giga-ohms,” he adds.

High-potential tests can be divided into three distinct tests with different goals. To understand the high-voltage capacity of an insulating material, dielectric breakdown test is used. The voltage between the test points is increased continuously until the current increases suddenly. This is the point where insulation gets into conduction. Normally, this test is done during the product design and qualification stage.

[stextbox id=”info” caption=”Types of leakage currents”]

During the insulation test, a high voltage is generated that causes a small current (in micro-amperes) to flow through the conductor and insulation. The amount of current depends on the amount of voltage applied, the system’s capacitance, total resistance and temperature of the material. The value of insulation resistance read on the meter will be a function of following three independent sub-currents:

Conductive leakage current. Conductive current is a small current that normally flows through insulation, between conductors or from a conductor to ground. This current increases as insulation deteriorates and becomes predominant after the absorption current vanishes.

Capacitive charging leakage current. When two or more conductors are run together in a raceway, these act as a capacitor. Due to this capacitive effect, a leakage current flows through conductor insulation. This current lasts only a few seconds as the DC voltage is applied and drops out after the insulation has been charged to its full test voltage. In low-capacitance equipment, capacitive current is higher than conductive leakage current, but usually disappears by the time you start recording the data. Because of this, it is important to let the reading settle out before recording it. On the other hand, when testing high-capacitance equipment, the capacitive charging leakage current can last a very long time before settling out.

Polarisation absorption leakage current. Absorption current is caused by polarisation of molecules within the dielectric material. In low-capacitance equipment, current is high for the first few seconds and decreases slowly to nearly zero. When dealing with high-capacitance equipment or wet and contaminated insulation, there will be no decrease in the absorption current for a long time.

—Prachi Gupta, director, Avante Global

[/stextbox]

[stextbox id=”info” caption=”Key safety points for test engineers”]1. Keep the unauthorised and unqualified persons away from the test area

2. Arrange the test bench and test procedure in orderly manner

3. Do not modify the test procedures without any knowledge

4. Make sure that custom test fixtures carry proper ratings and test equipment are correctly rated

5. Do not touch the DUT while the test is running

6. In case of a problem, first turn off/stop the test

7. Discharge the DUT completely in the DC test[/stextbox]

“Of course, the sample DUT that fails the test is rejected as it is completely damaged now,” shares Manwani. The dielectric withstand test is normally done at 75 per cent of the breakdown voltage. The test is performed to understand for how long the dielectric can withstand high voltage.

Insulation resistance (IR) test measures resistance of the insulating material. You apply a very high voltage across the dielectric, carefully measure the current and calculate the resistance using Ohms law. “For most of the products, the test is carried at 500V DC and the resistance should be at least 2 mega-ohms,” shares Ms Wang. “Usually IR is checked first, before putting the device for HIPOT test,” she adds.

Hipot testing can be carried by an AC or DC voltage. However, there are different considerations when using AC or DC voltages. The difference in the reading becomes significant when the DUT is highly capacitive. “AC voltage cannot charge a capacitive load, as reactive current flows instantly and remains consistent regardless of the time the voltage is applied. DC voltage will charge the capacitance of the DUT so you may see an inrush of current upon initial application of the voltage, but gradually the readings will dissipate as the DUT becomes charged. Normally, the relationship between AC and DC HIPOT tests is AC=1.414DC. For example, if you perform AC HIPOT test at a test voltage of 2 kV, then DC HiPOT test should be performed at 2.83 kV,” explains Ms Wang.

Expressing her views on the test methodology, Ms Gupta believes that the test method also depends on the type of the DUT. “For instance, when a low-capacitance equipment like electrical cabling or switchgear is tested, the time-dependent capacitive leakage and absorption leakage current become insignificant and decrease to zero almost instantly. This provides a perfect condition for accurate spot reading. On the other hand, when high-capacitance equipment such as long runs of cables,

large motors or generators are to be tested, the time-dependent current will last hours. This current will cause the meter reading to change constantly, making it impossible to obtain an accurate steady reading. This condition can be overcome by using a test that establishes a trend between readings, such as the step voltages or dielectric-absorption test. These tests do not depend on a single reading but on a collection of relative readings.”