New features in HIPOT testers

To serve the rising demands for features and, most importantly, safety, there have been a lot of developments in the design of HIPOT testers and features. Most companies are promoting their all-in-one kinds of equipment that can perform dielectric breakdown, dielectric-withstand and insulation resistance tests from a single box. Many equipment are designed to perform both AC as well as DC HIPOT test.

Handheld portable testers are now the need of every industry. The need for insulation testing is increasing in the field and traditional testers are large and bulky. “Nowadays, battery-operated insulation testers are there to work in the field. Good-quality probes are available in the market to do the test efficiently,” informs Manwani.

Some T&M manufacturers have launched a thoughtful combination of insulation tester and digital multimeter in a lightweight tool that fits in your palm. This has significantly helped electricians and technicians on the field in troubleshooting and preventive maintenance, addressing their basic multimeter needs, and gives them an insulation tester that generates up to 1 kV.

“Humidity is a major factor affecting insulation measurements in India. Nowadays, insulation testers are designed to be humidity-proof,” shares Thirumalaisami R., head of T&M, Yokogawa, India. “During the DC HIPOT test, the DUT is fully charged to provide accurate leakage current. Normally, to discharge the testers, the probes are shorted. This reduces the battery and instrument life. Today, testers have a built-in discharge key with which the battery and instrument life are optimised,” he adds.

As per ISI requirement, insulation is to be tested for 500V DC, but today industries require various higher and wider voltage ranges. Manwani shares, “Insulation testers or million mega-ohm meters with analogue meter are preferred because of the non-linear scale of insulation. These instruments cover most of the higher-range requirements and are indigenously developed and available. Digital insulation testers are also available but these have limited range.”

“Today HIPOT testers come with a digital LCD. This is not only for ease of use but also to reduce the operator error,” Ms Wang believes. “The market demands fully-automatic all-in-one testers, so the manufacturers have come up with 4-in-1 and 5-in-1 kinds of electrical safety test solutions,” she adds. “Thoughtful safety, reliable test result, user-friendliness and fully automated interface make these equipment an advanced safety tester that can perform essential electrical safety tests and deliver fast and reliable test results from a single test connection.”

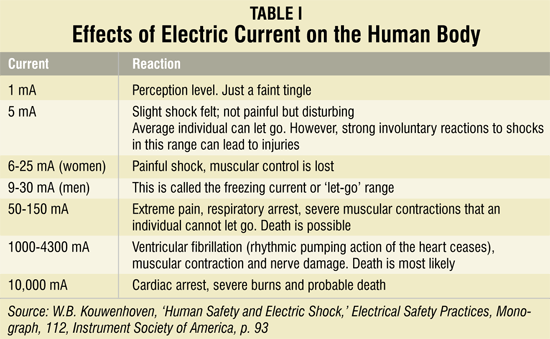

The output of the HIPOT tester is normally high voltage and current. If mishandled, this can prove dangerous to the person performing the test. Automation of the tests has in a way helped the operator to be away or have minimal contact for handling of the device. However, safeguarding the operator is still utmost important. Equipment today come with interlock features, ground fault interrupts, faster DUT discharge and quick high-voltage shutdown. These also include audio-visual warnings like blinking LEDs and alarms in case of any unforeseen situation.

Choosing HIPOT tester

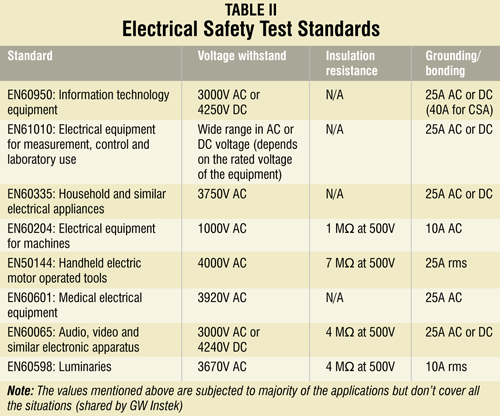

Understanding when to use AC test or DC test is important. Some standards may require either of the two or both. AC test scores over DC as it tests the insulation for both polarities. However, the downfall is that in the case of a highly capacitive DUT, the discharge current will be higher, misleading the real current reading. In such cases, choose a tester with high output current capacity.

As there are several combinations of multiple test equipment available, choosing the right combination is important. If the tester combines HIPOT tester and ground-bond tester, ensure that the tester can handle the output current and resistance measurement required.

Some tests are performed during designing before finalising the material, while many tests are performed during production. It makes a lot of sense to combine the tests during production into one equipment.

Ms Wang adds, “The leakage current test is performed by most of the DUTs at 10% sampling rate except in the case of medical equipment (this means leakage current is tested only on ten samples if 100 samples are provided). Hence manufacturers don’t perform leakage current test on the production line.”

She suggests that since most of the standards require insulation resistance to be tested at 500V and 1000V, test voltage for IR is fixed at these values.

Time to test is another important consideration. Standards play an important role in the duration of the test. As all-in-one kinds of boxes have a single connection, these save a lot of time because of simultaneous operation. Functioning and line leakage are tested with the same connection.

To conclude

With so many technologies working together, and developments in electronics, HIPOT test is becoming a necessity and a routine in production line testing. Today, consumers look for products that are not only feature-rich but also safe to use. With a little understanding of the basic test procedure, and use of the right type of test and equipment, you can perform the tests safely. This will ensure compliance to regulations and guarantee that your product is safe to use.

The author is a senior technology journalist at EFY