An LED light manufacturing unit was working on a 150-watt streetlight project wherein the engineering design team had to rack their brains for a long time over an issue. Their LED supply boards were malfunctioning because the controller ICs would burn out within a few seconds.

Later the team realised that the ICs were faulty. The IC manufacturer had to confess about the signal losses arising from the use of poor-quality controller IC. The internal built of the IC was not reliable and had issues with the layout. The entire issue came to light only after the ICs were tested on a signal integrity (SI) measurement instrument.

Likewise, designers have reported component failures when these were not tested with power integrity (PI) measurement tools.

Need for signal and power integrity

While measuring critical parameters like drain-to-source voltage of MOSFETs, design engineers face frequency fluctuations or varying time-periods as a result of signal integrity issues. These occur due to ground bounce or poor signals, or due to signal losses and power supply noise. Similarly, each electrical system has its own impedance, which can be impacted due to power integrity issues. Thus, to get the benefits of clean data, time saving and more reliable products, signal and power integrity instruments become a necessity.

Market overview

In late 1990s signal integrity issues were common, so designers focused on traces and path of the PCB design too. And now the power supplied to circuits has also become a matter of concern as it gives rise to power integrity issues.

Today, designers work on high-speed designs, where signal integrity and power integrity analyses are equally important. Power integrity issues in a design can actually occur as signal integrity issues. As designs become increasingly compact, design engineers are facing far too many integrity issues, which has created a demand for constant upgrades in measurement tools.

Troubleshooting with MSO

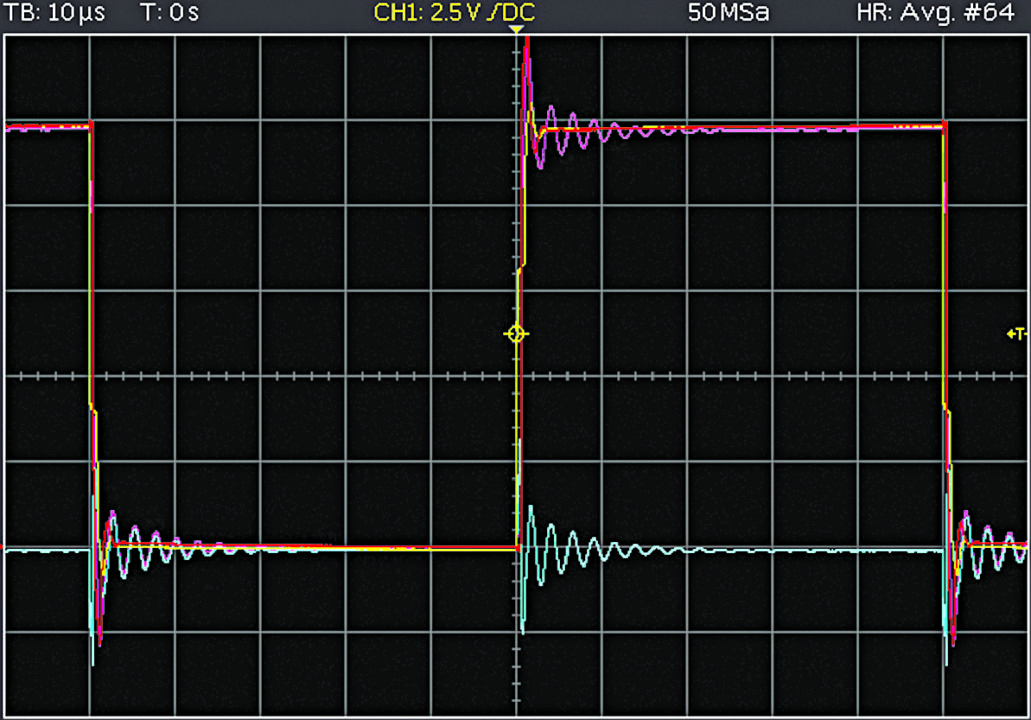

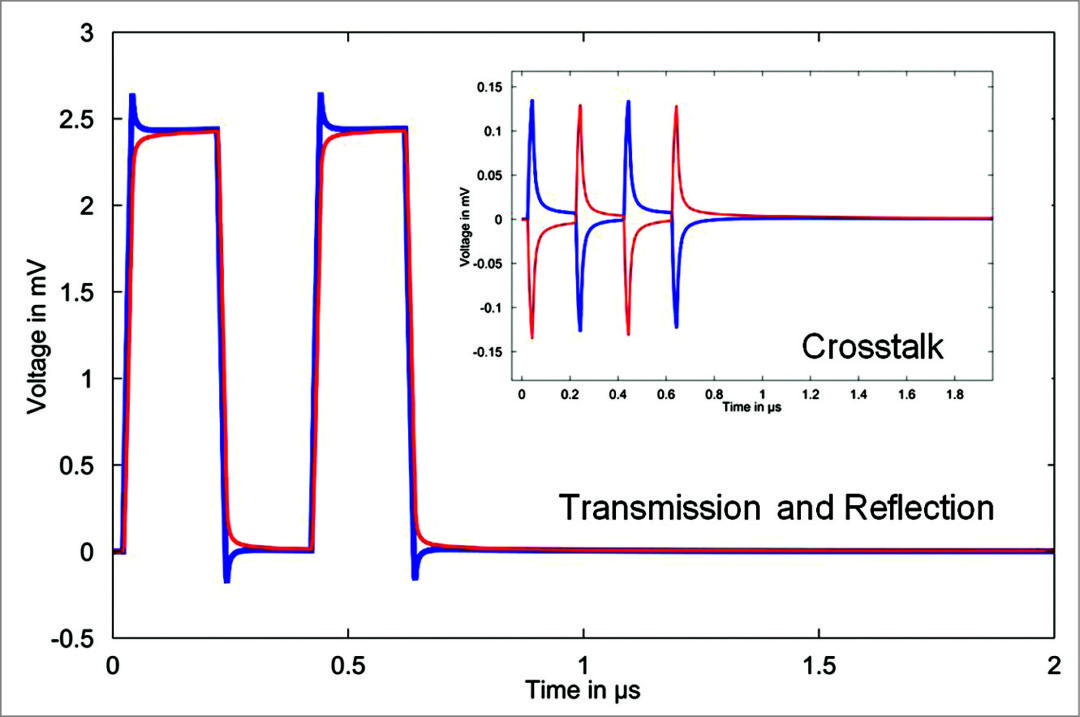

Signal integrity issues in analogue domain include impedance mismatch, crosstalk and transmission-line effects, while digital issues are setup and hold violation.

As analogue signals are responsible for digital signal mismatch, mixed-signal oscilloscopes (MSOs) have been introduced in the market that give a combined result of analogue and digital signals. Thus, a designer can monitor several points in a design simultaneously.

MSOs are a powerful tool for troubleshooting signal integrity problems.

Enhancing probes to increase the accuracy

Companies have also introduced low-current probes in oscilloscopes to improve the measurement accuracy. These upgrades focus on low-current measurements for small applications such as LED drivers and now feature 1GHz frequency.

Ultra-low-capacitance probes have also been introduced with wide bandwidths at probe tips, while the size of the probe tip has been reduced to avoid shorting between components in densely-packed circuit boards. Thus, these provide signals to the acquisition system correctly.

Measuring SI with VNA using frequency multipliers

Due to the demand for higher-data-rate devices, signal integrity (SI) test has become more important nowadays. Earlier, vector network analysers (VNAs) were only used to measure ‘S’ parameters (input-output relationship between terminals in an electrical network) in telecom instruments, but now these have been upgraded to cover signal integrity also. These VNAs work in frequency domain and have now been upgraded to 120GHz.

VNAs are used for micro-level applications like PCB analysis, where these can point out problems like crosstalk, track discontinuity and copper trace width.

There may also be instances of signal fluctuations, called jitters, which mainly occur in clock circuitry but can also arise from power supply noise, crosstalk or even phase-locked loop circuits.

Madhukar Tripathi, senior manager, marketing and channel sales, Anritsu India, says that to increase the frequency bandwidth of vector network analysers, external frequency multipliers are added as per the application requirements, like an antenna that needs to operate beyond 100GHz.

Thus, testing of high-speed digital circuits or high-bandwidth devices becomes easy for designers, saving their precious time to innovate for future. Tripathy notes, “VNA upgrade has brought about just 20-40 per cent increase in existing prices.”

Standby power measurement using power analysers

Power integrity device players too have introduced upgrades, though at a small scale, to measure voltage and current parameters responsible for power integrity.

Traditionally, power analysers have been used to measure only the input parameters of a line property, when connected on the input side. However, now these have been upgraded to measure power integrity as well. These are placed on the output side of the product to measure output parameters and check power integrity.

Nitin Nigam, application engineer, Tektronix, tells that the bandwidth of power analysers has been increased to use them for PI measurement and also meet application requirements. He adds that power analysers are now coming with an additional functionality of standby power mode.

This has been introduced following the government’s directive to save power when devices are not in use. Like mobile chargers, all systems consume a small amount of power even when there is no load but the mains supply is ‘on.’ A power analyser as a PI instrument measures the system’s power consumption in standby mode. So, products that are tested for power integrity, give consumers the benfit of power saving. Monetarily, it is a huge benefit to the manufacturers as well.

In power integrity measurement, oscilloscopes with limited bandwidth are preferred as these produce less noise. If a measurement does not require the bandwidth to be extended, the bandwidth is limited to reduce the noise produced.

The way forward

Earlier, designers used post-layout analysis, which didn’t guarantee design success. But now by using high-speed design, analysis and verification techniques early in the design phase, designers can eliminate layout iterations and deliver products on time. As SI and PI issues will continue to remain a big concern, the measurement market will evolve and merge to make it easier for designers. But, at present, a more practical approach to measure power integrity and signal integrity is to have instruments that measure them separately.