Such thorough testing of the solar cell is often done in space applications, where verifying quality and reliability is essential. Testing a solar cell in a dark chamber causes the cell to behave essentially as a diode with some resistance characteristics. With no light stimulus applied to the solar cell, dark testing requires a DC source that only has the ability to source or output current. Dark testing does require both positive and negative voltage to test the I-V curve. The negative voltage is used to reverse the cell’s bias, which approximates the parallel resistance of the cell (Rp) and the breakdown region of the diode.

The measurement set up for measuring the I-V curve performance of cells, modules and arrays is built with power supplies, switch/measurement units, electronic loads and digital multimeters. The set up should be capable of measuring the I-V curve performance of cells, modules and arrays in both forward and reverse polarities, in full radiation, and in shadow (darkness).

DC power source. A DC power supply capable of providing voltage in forward and reverse polarities is needed for measurement of the performance of a solar cell or module. The power supply acts as a variable voltage load when the solar device is illuminated, which enables measurement of the power I-V curve. When the solar device is dark, voltage is applied in both forward and reverse directions and you can measure the entire dark I-V curve.

Complete characterisation of a solar device generally requires a four-quadrant-capable power source. A four-quadrant DC source, capable of negative voltages and negative currents is often used for solar cell-testing for two reasons. The first is to overcome any series resistance in the cell; the second reason is that using negative voltage values may be desirable to reverse the cell’s bias to fully characterise the cell’s electrical properties.

Measuring the I-V performance of an illuminated solar device requires the power supply to sink current while sourcing positive voltage. Measuring the I-V performance of a dark cell requires the power supply to source positive and negative voltage and current to cover the full range of solar device operation.

A bipolar power supply is generally the instrument of choice. If a bipolar source is not available, a pair of two-quadrant power supplies configured appropriately can be a viable alternative. Power supplies 661xC and 663xB of Agilent Technologies among other OEMs are typical examples of DC power source.

Electronic loads. Electronic loads are solutions for solar module testing because of their wide power range and ability to sink large amounts of current. Electronic loads typically have three modes of operation—constant current (CC), constant voltage (CV) and constant resistance (CR). CV is the preferred mode of operation for I-V curve tracing because it allows stepping through voltages incrementally and measure the current output of the module under test.

For testing outdoors, or in other places where environmental temperatures vary widely, an electronic load that provides temperature coefficient specifications is highly desirable. Variations in environmental temperatures change the measurement specifications of the load’s built-in measurements, leading to increased measurement uncertainty. Temperature coefficient specifications allow for compensation of environments with wide temperature variations.

Switch and measurement instrument. In solar cell and module testing, measurement of parameters other than I-V curve such as temperature and calibrated reference cells are also required. Temperature has a direct effect on the output power of the cell or module. Calibrated reference cells are often needed to gauge the effectiveness of the light source used to power the solar cell or module. A switching configuration can also be used to allow multiple solar cells or modules to be tested in parallel.

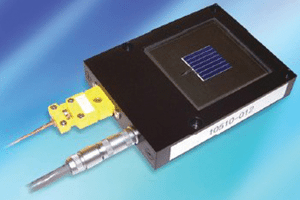

Reference cells. These are an integral part of solar simulator calibration and solar cell I-V characterisation. Reference cells consist of a readout device and a 2×2cm² calibrated solar cell made of mono-crystalline silicon. It reads solar simulator irradiance in ‘sun’ units; one sun is equal to 1000 watts per metre square at 25°C and air mass 1.5 (global reference). The window’s material is determined by the type of cell being tested, to reduce spectral mismatch.

Solar simulators. Solar simulation system, or sun simulator, reproduces full spectrum light equal to natural sunlight and provides controlled environment to measure solar cell’s performance. Solar simulators expose solar cells to light in a testing environment with a controlled spectrum and perfect lab conditions. This provides a true power-output reading for solar cells.

The simulator consists of a light source and a power supply. The power supply unit provides constant electrical power to the xenon arc lamp. The radiation from the lamp is focused onto an optical integrator that helps produce a uniform diverging beam. The output is a uniform beam that closely matches the sun’s radiation spectra for a given air mass.

Solar simulators have following applications for measuring of photovoltaic cell’s performance:

1. Determining electrical performance of PV cells

2. Comparing cell’s characteristics among group of cells or different cell designs

3. Repeated measurement of the same cell to study life-cycle performance changes

4. Steady-state testing of PV modules

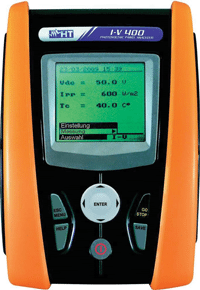

Portable/handheld measuring instruments

Portable/handheld instruments are required for field measurements.

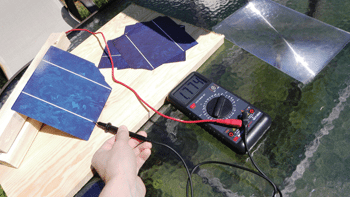

Multimeter. It is a handheld measuring instrument for ordinary and scheduled maintenance of photovoltaic systems. It is a multi-function electric test device that carries out field measurement of the I-V characteristic—both of a single module and module strings. The instrument measures the I-V characteristic, temperature and incident irradiation of the device being tested. The acquired data is then processed to extrapolate the I-V characteristic at standard test conditions (STC) to compare with the nominal data declared by the modules’ manufacturer.

Irradiance meter. Handheld solar radiation meters are used when testing the output of a panel. This device measures the watts per metre square of light.

The author is joint director (technical training) with EFY Tech Center, New Delhi