The introduction of fully-integrated and reliable vibration sensors can enable autonomous and configurable operation. With these, predictive maintenance program developers can significantly improve the quality and integrity of the data collection process without the limitations and compromises posed by past vibration analysis approaches

BOB SCANNELL

SEPTEMBER 2011: Precision industrial processes are increasingly reliant on efficient and consistent operation of motors and associated machinery. Imbalances, defects, loose fittings and other anomalies in the machinery typically translate into vibration, resulting in loss of precision as well as safety concerns. If left unaddressed, besides the performance and safety issues, loss of productivity becomes inevitable if equipment needs to be taken-off the line for repair.

Condition-based predictive maintenance is a known and proven approach for avoiding productivity loss. But this approach has its complexities. Existing methods have limitations, particularly when it comes to analysing the vibration data and isolating error sources.

Existing data collection approaches include simple piezo-based sensors mounted to the machinery and handheld data collection tools. These methods have a number of drawbacks, particularly when compared with the ideal solution of a complete detection and analysis system, which can be embedded in the machinery and act autonomously.

The introduction of fully-integrated and reliable vibration sensors have the ability for autonomous and configurable operation. With these, predictive maintenance program developers can significantly improve the quality and integrity of the data collection process, without the limitations and compromises posed by past vibration analysis approaches.

Repeatability of measurements

Handheld vibration probes offer some implementation advantages. These do not require any modification to the end-equipment, and given their large (brick) size, these are relatively highly integrated, allowing sufficient processing and storage. However, a major limitation is the repeatability of the measurements. Slight differences in the probe location or angle produces inconsistent vibration profiles making time comparisons inaccurate. Thus, the maintenance technician is left with the question of whether any observed vibration shift is due to an actual change within the machinery, or just a change in the measurement technique. Ideally the sensor would be both compact and integrated sufficiently to allow direct and permanent embedding within the equipment of interest.

Scheduling of measurements

Another limitation of the handheld probe approach is the lack of real-time notification of troublesome vibration shifts. The same is true for most piezo-based sensors, which are typically at a very low level of integration (transducer only in some cases) with the data transferred elsewhere for later analysis. These devices require external intervention and thus present an opportunity for missed events/shifts.

On the other hand, an autonomous sensor processing system that includes sensor, analysis, storage and alarm capability, and is still small enough for embedding, offers the fastest notification of vibration shifts, as well as the best ability to show time-based trends.

Understanding the data

The ideal real-time notification from an embedded sensor is only possible if frequency domain analysis is employed. Any given equipment typically has multiple sources of vibration such as bearing defect, imbalance, gear mesh and by-design sources such as a drill or machine press producing vibration in normal course of operation. A time-based analysis of the equipment produces a complex waveform, combining these multiple sources, which provides little discernible information prior to fast fourier transform (FFT) analysis.[stextbox id=”info”]Use of vibration sensors can reduce avoidable equipment repairs, which are a major contributor to lost productivity in industrial manufacuring processes[/stextbox]

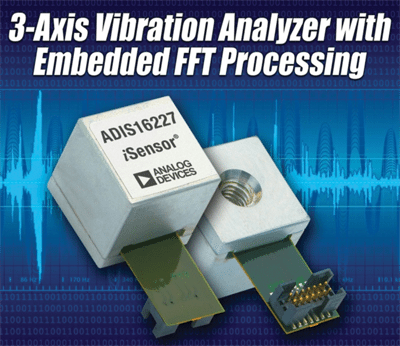

Most piezo-based sensor solutions rely on external computation and analysis of the FFT. This not only eliminates the possibility of real-time notification but also puts substantial additional design burden on the equipment developer. With embedded FFT analysis at the sensor, vibration shifts can be isolated to specific sources immediately. Such a fully-integrated sensor element could also reduce development time for equipment designers by six to twelve months, given the completeness and simplicity of a fully-integrated and autonomous sensor.

Accessing the data

Embedded FFT analysis assumes that the analogue sensor data has been conditioned and converted to digital, and thus data transmission is greatly simplified. In fact most vibration sensor solutions in use today are analogue output only leading to signal degradation during transmission. Not to mention the complexity of off-line data analysis.

Most industrial equipment that require vibration monitoring tend to exist in noisy, moving, inaccessible and even dangerous environments. Thus, there is a strong desire to not only reduce the complexity of interface cabling but also perform as much of the data analysis as possible at-the-source to capture the most accurate representation of the equipment vibration as possible.

How much data

Many existing sensor solutions are single-axis piezo transducers. These piezo sensors provide no directionality information and thus limit the understanding of the equipment vibration profile. The lack of directionality translates to the need for very low-noise sensors, which also impact cost. The availability of tri-axis microelectromechanical systems (MEMS)-based sensors allow a significant increase in the ability to isolate the vibration source, while potentially improving cost.