The International CES is an indicator of promising technologies, and this year 3D printing was an extremely popular theme, along with the Internet of Things, wearable devices, 3D televisions and other emerging tech. As Avi Reichental, president and CEO of 3D Systems wisely pointed out at the event, “3D printing is an overnight success 30 years in the making.” But then, it is true that a few years ago MakerBot was perhaps the only 3D printing player at CES. Today, there are several players vying to capture this growing market, including XYZ Printing, 3D Systems, MakerBot and more.

It is also interesting to note that these printers are getting more and more versatile and cost-effective too. There are sub-$500 models such as Printbot Simple and Da Vinci 3D Printer. There are those like Replicator Mini, Solidoodle and Cube3, which are priced quite effectively for their capabilities. And, there are also innovative, awe-inspiring ones like the ChefJet 3D Pro that can print edible food models in full colour!

The trend is rather strong, and it is obvious that today it is technically possible to create anything from food and toys to weapons and prosthetics using these 3D printers. While currently 3D printers have not captured the fancy of home users due to the lack of simple and user-friendly software tools, a research report released this April by Juniper Research says that sales of 3D printers for home-use will exceed one million units by 2018, thanks to killer apps, expansion of use cases and entry of established players like HP.

The industry and academia are also in tune with this trend, and are gearing up with improved technologies, materials and processes to take 3D printing to greater heights. Here is a sample of some such R&D activity in the 3D printing space and innovative applications of the same.

Building dream homes. Kamermaker, which means ‘room builder,’ is an open source 3D printing pavilion developed by Ultimaker. The six metres tall printer builds large plastic-based building blocks that can be used in construction. And these building blocks are nothing like the rectangular bricks used in construction. They are large chunks of the building itself—say a quarter of a room or a staircase—which just need to be patched together to make the house.

A Dutch architectural firm is now working on building a canal house in Amsterdam using the Kamermaker. The project is apparently an experiment that applies 3D printing to construction, and so the architects have left the construction site open to public viewing. They believe that they might have to re-build parts of the house several times till they arrive at the perfect design. This demonstrates the flexibility that 3D printing offers. The canal house might mark the beginning of an era where people can buy architectural designs off stores and have their house printed within weeks.

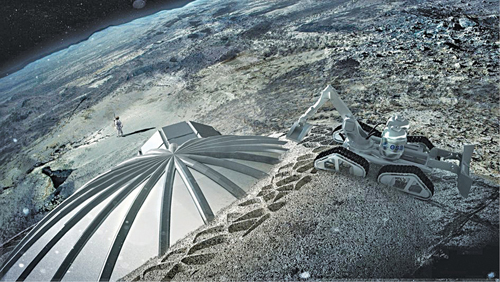

Space stations too. Last year, the European Space Agency (ESA) teamed up with architects to test the use of 3D printing for more efficient lunar base construction using materials like moon dust. The lunar base, designed by Foster+Partners, has a multi-dome design with a cellular structured wall as protection against micrometeoroids and space radiation. It has inflatable structures to accommodate astronauts. The lunar base is being 3D printed using a special printer supplied by UK-based Monolite. As a demonstration, they have printed a 1.5-tonne building block using lunar soil. The block has a hollow closed-cell structure inspired by bird bones, to provide the right balance of strength and weight.

Lord Brahma has competition. Bio-printers are capable of 3D printing human tissue too. Using bio-ink made of living cell mixtures, human tissue can be printed layer by layer. Layers of hydrogel applied between layers of cells work as a scaffolding. Once the cells fuse, the hydrogel is removed. This structure is then transferred to a bioreactor for Nature to work her magic. The tissue grows naturally into its final form.

Today, scientists are able to print tissues such as skin and cartilage but there is hope that life-saving organs will be printed in the future. In a recent breakthrough, Harvard researchers have applied micro-scale 3D printing to create tissue containing skin cells and biological structural material interwoven with blood-vessel-like structures. Using a customised four-head 3D printer, they have created hollow, tube-like structures within a mesh of printed cells using special ink that liquefies as it cools.