Technology gets better by the day. Big names, like Autodesk and HP, have decided to enter the industrial 3D-printing market. Canon is expected to follow shortly. “Though these are high-end and not affordable for hobbyists or small/medium scale companies, there are a lot of start-ups focussed on delivering qualitative machines at affordable prices,” says Surendranath Reddy, founder and CEO, Redd Robotics and 3D-ing. He adds, “Particularly in India, with the Make In India movement catching up, we are expecting exports of 3D printers to happen in a big way.”

Interesting activities triggered by 3D printing

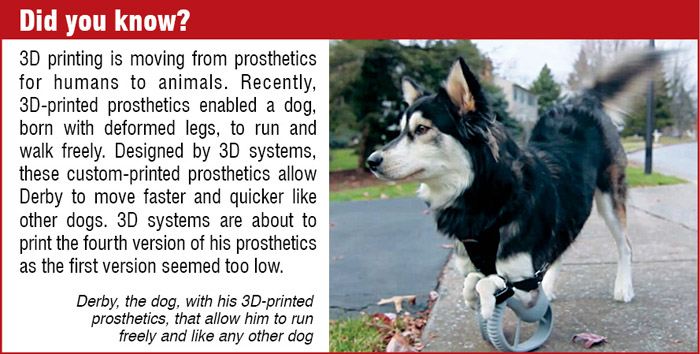

In medical field. 3D-printing technology is a very rapidly developing field. Every day we hear of new things that are being done with the help of 3D printing. Shishodia says, “Printing computerised tomography (CT) scans of patients provide doctors with exact moulds required for producing transplant parts. A patient was recently transplanted with a 3D-printed titanium facial implant. There are research labs working on printing complete organs using 3D printers by using amino acids and other life-forming chemicals, such as ink.” He adds, “A home project started by a father by printing a prosthetic hand for his son has taken the shape of a massive revolution of 3D-printed prosthetics.”

In space. Talking about the world of space exploration, imagine a day when an astronaut is on Mars and something breaks. What does he or she do when in urgent need of a replacement? In space, where there is no comfort of overnight shipping, to be able to make parts on demand will forever change that situation for astronauts. With 3D printers, an astronaut has the ability to make whatever is needed, right there on the spot.

For instance, recently NASA printed tools on International Space Station (ISS), shares Shishodia. He says, “You transmit something from somewhere and it appears somewhere else within a few minutes.” The 3D printer printed a tool with a design file transmitted from the ground to the printer at ISS. The tool was a ratchet wrench.

In consumer sector. 3D printing is helping convert ideas to physical products faster than expected. The evolving eco-system is allowing product designers and marketers to market their products faster and enabling the product delivery process, informs Mishra. He says, “Companies, like Amazon, Microsoft and FedEx, are helping create a business for personalised items, such as phone covers, figurines, 3D-printed jewellery and many such products.”

3D printers are fostering customisation as well, informs Vivekanandhavarma Datla, head-Manufacturing Engineering Solutions, Cyient Ltd. He says, “Personalised, custom-printed iPhone cases are just the beginning of an era of hyper-customisation, potentially achievable through 3D printing.”

In robotics and DIY community. Here too, 3D printing has been a boon. It is enabling printing of various small parts designed by makers for their projects. Such ease of fabrication would not be possible without 3D printing.

3D printing offers great amount of freedom to engineers

“From desktop to desk in a few minutes,” summarises Shishodia the process of 3D printing. With 3D printing, an engineer can have a prototype of his design ready within a few minutes to a few hours by printing it on his desk.

3D printing aids in converting an idea into a physical product in the quickest possible time. Speed to market is the biggest gain for engineers using this technology, believes Datla. He notes, “There is a paradigm shift from ‘design for manufacture’ to ‘manufacture anything that can be designed.’”

With 3D printing becoming faster and cheaper, engineers will have the luxury of modelling and prototyping more of their designs before production, feels Sidhant Pai, CEO Protoprint Solutions Pvt Ltd. He says, “The ability to physically test their models will likely lead to better and more usable products. Additionally, high-quality 3D printing will enable customised add-ons to user products, freeing product designers to factor in personalisation in their designs.”

While there are desktop 3D printers available from popular companies, engineers also go for DIY kits that prove to be slightly cheaper and also give them an insight into the nuances of 3D printers during the course of the build, notes Shishodia. He says, “Open source 3D printers, like Prusa i3 and OrdBot Hadron, are quite popular among the DIY 3D-printer community.”

Talking specifically about how specifications of today’s printers could help engineers, Reddy says, “In FDM, techniques like auto-bed levelling help by reducing users’ interventions. Algorithms that make the 3D printer’s tool head move slowly at curves, intricate designs or small objects, increases the cool-down time and quality.” He adds, “Different approaches of a machine’s mechanical designs, such as coreXY mechanism, helical or delta-styled 3D printers, are opening up more possibilities for machine features.”