At C-DAC Kolkata, e-tongue for determining the briskness/strength of the black tea liquor has been developed. The virtual instrumentation-based e-tongue uses voltammetry technique for correlating the briskness/strength of tea liquor with the ‘tea taster’ mark. In this work, an array of selected electrodes was immersed into black tea liquor-samples for analysing the tea samples. A computational model was developed to correlate the measurements with the tea taster’s briskness/strength scores. The developed e-tongue structure is shown in Fig. 8.

[/stextbox]

[stextbox id=”info” caption=”INNOVATIONS”]

4. GSM-based remote operation of agricultural equipment

Bengaluru based Rural Bridges’ Kisan Shakti is an easy-to-use and economical communication device which enables a farmer to operate his motor pump set from anywhere through his mobile or landline. The GSM-based controller can be fitted to all the existing motor starters and used with mobiles or landlines of any operator.

How it works? A farmer simply calls Kisan Shakti and selects the options provided by the interactive voice response system (IVRS) menu in the local language to switch on/off of the motor. He gets the confirmation of the operation performed along with running status of the motor and also if water is being pumped or not immediately from the IVRS menu. Advanced technological features of the device ensure instant communication to the farmers whenever power is available, and also in cases of faulty power supply, lack of water in the well/bore and attempt of device theft. The device raises an alarm and makes a phone call to the farmer if anyone tries to steal it or any device connected to it. There are different modes of operation to suit the needs of the farmers—auto, manual and timer—indicated by three LED indicators. The device is adaptive to any motor configuration up to 20 HP.

[/stextbox]

[stextbox id=”info” caption=”INNOVATIONS”]

5. ePest surveillance system

Infronics Systems in association with the Food & Agriculture Organisation (FAO) and Ministry of Agriculture, government of India, has developed an ePest surveillance system called Fieldman. It offers a uniform and standardised process for pest surveillance and data collection from the agricultural fields to monitor and ascertain the health of the crop, and issue timely advice to farmers.

The system is an amalgamation of embedded and communication technologies on a single platform. There are plug-in sensors for automatic data collection. The GPS module enables collection of geo-referenced data and the GPRS/GSM module ensures connectivity through the telecom network. The data collected from the fields can be uploaded to a central location for analysis by experts.

The ePest surveillance system also includes an extensive suite of software applications—both on the Fieldman handheld system and back-end server—to offer uniform surveillance protocol for field data collection about pests.

[/stextbox]

[stextbox id=”info” caption=”INNOVATIONS”]

6. Plantation management using wireless sensor network

For developing an efficient system of plantation management, the foremost input is the availability of accurate data. This data includes soil properties, agronomic data, physicochemical parameters, atmospheric data, etc, preferably on a day-to-day basis or even hourly basis. Normal laboratory analysis of these parameters and manual decision-making take a long time even with the most sophisticated analytical techniques.

Most of the sampling procedures are not in-situ and samples have to be brought from the field to laboratories for analysis, a lot of time. By the time the results are available and decisions taken, the farm conditions might change making the decision inappropriate. Quick and quality decision-making at the farm level can enhance agricultural productivity and quality manifold.

Computer-aided decision-making process can handle and analyse several input parameters at the same time involving large databases.Monitoring of physical and environmental parameters including soil moisture, soil temperature, soil pH, leaf temperature, relative humidity, air temperature, rainfall, vapour pressure and sunshine hours is done through a wireless sensor network (WSN).

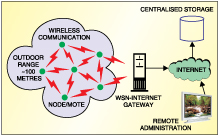

WSN comprises spatially distributed sensors to monitor physical or environmental conditions. It is a comprehensive system that integrates sensing, wireless and processing technologies and is capable of spatially and temporally sensing different physical parameters without loss in the sensing accuracy. The parameters are processed and wirelessly transmitted to a centralised data storage system through a gateway from where they may be remotely accessed and analysed by the user.

The system architecture of a WSN-based system consists of different sensors interfaced to electronic hardware with data processing capabilities. The electronic hardware is also equipped with wireless communication modules allowing the sensed data to be processed and transmitted according to a select protocol. These hardware nodes are called motes in WSN terminology. Each of the motes is interfaced with a set of sensors depending on the application domain. The sensors may be programmed to sense at specific intervals or periodically in a day.

WSN in agriculture. WSN technology can broadly be applied into three areas of agriculture: fertiliser control, irrigation management and pest management.

The sensors that can be interfaced to the mote are temperature, relative humidity, solar radiation, rainfall, wind speed and direction, soil moisture and temperature, leaf wetness, electrical conductivity and soil pH sensors. These sensor-readings can be integrated with a decision support system that aids the management of resources to the crop. Given below is a brief note on automated drip irrigation system.

Drip irrigation automation. Conventional irrigation methods like overhead sprinklers and flood-type feeding systems usually wet the lower leaves and stem of the plants. The entire soil surface is saturated and often stays wet long after irrigation is completed. Such a condition promotes infections by leaf mold fungi. Flood-type methods consume a large amount of water, but the area between crop rows remains dry and receives moisture only from the incidental rainfall.

The drip or trickle irrigation technique slowly applies a small amount of water to the plant’s root zone. Water is supplied frequently, often daily, to maintain favourable soil moisture condition and prevent moisture-stress in the plant with proper use of water resources.

WSN-based drip irrigation system is a real-time feedback control system which monitors and controls all the activities of the drip irrigation system. A typical system includes a delivery system, filters, pressure regulators, valves or gauges, chemical injectors, measuring sensors/instruments and controllers.

WSN framework installed in the field may gather various physical parameters related to irrigation. These include ambient temperature, ambient humidity, soil temperature, drip water temperature, soil moisture, soil pH, water pressure, flow rate, amount of water, energy calculation (power), sunlight condition, chemical concentration and water level.

The data is sent to the central server wirelessly through the motes and gateways. Based on the data ranges, the central server generates necessary control actions, which are routed to the respective controllers through control buses enabling implementation of closed-loop automation of the drip irrigation system.

The basic feature of the product is to enable switching on and off of the motor remotely. The device ensures that all the fault conditions are checked and only then the motor is started.

[/stextbox]

The author is associate director at Centre for Development of Advanced Computing (C-DAC), Kolkata