AI with ML swiftly predicts, minimises development time, and optimises synthesis, eliminating trial and error—for a future of advanced, efficient material manufacturing.

Artificial intelligence (AI) refers to the ability of a computer system to replicate human cognitive abilities, including learning and problem-solving skills. Although AI and machine learning (ML) are intricately related, they are distinct concepts. Machine learning is regarded as a subset of AI, indicating that it is a specialised area within the broader field of artificial intelligence. The relationship between artificial intelligence and machine learning provides significant advantages for businesses across diverse sectors, with constantly evolving opportunities and potential applications.

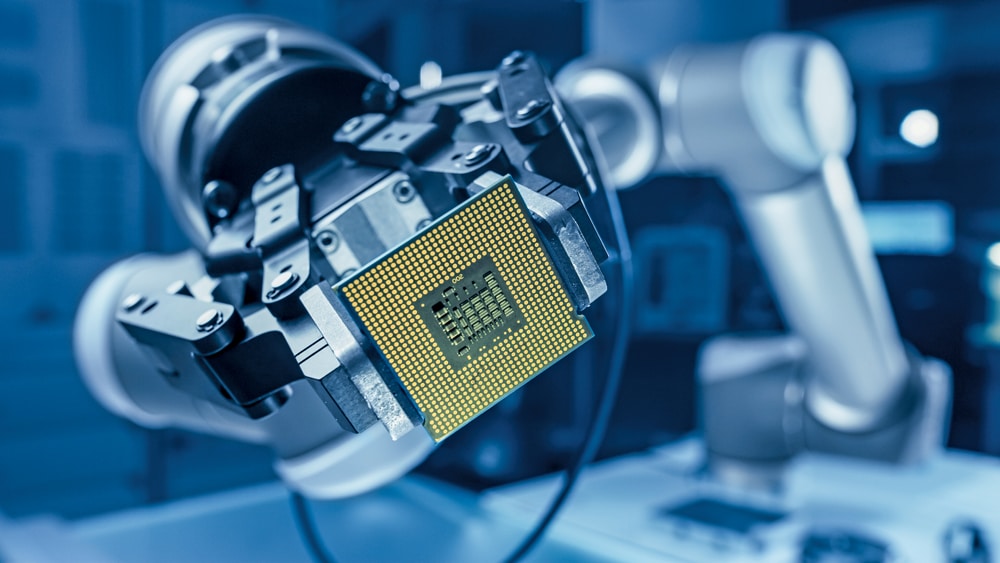

The integration of AI and ML technologies has revolutionised various industries, and material manufacturing is no exception. This article explores the significant role AI and ML play in optimising and enhancing the entire material manufacturing process, from material design and synthesis to quality control and predictive maintenance. We delve into various applications, challenges, and future prospects, showcasing how these technologies are contributing to the evolution of the material manufacturing sector.

Material manufacturing has been a cornerstone of human civilisation, driving technological advancements and economic growth. Traditionally, material development and manufacturing processes relied on empirical knowledge, experimentation, and trial-and-error methods. However, with the advent of AI and ML, the industry has witnessed a transformative shift. These technologies offer powerful tools for optimising material properties, improving production efficiency, and ensuring product quality.

Materials design and synthesis

AI has revolutionised the materials design and synthesis phase by accelerating the introduction and predicting the interaction of novel materials with desired properties. Researchers can leverage AI algorithms to predict material properties based on chemical composition, crystal structure, structural interactions, and other physical and chemical factors. ML models trained on vast material databases can generate valuable insights, leading to the creation of new formulations tailored for specific applications.

Materials property prediction

AI-driven materials property prediction models can significantly reduce the time and cost required for material development. These models utilise data from various sources, such as quantum calculations, experimental data, and simulations, to predict material properties like mechanical strength, electrical and thermal conductivity, and thermal stability, etc. Researchers can use these predictions to identify promising candidates for further study, expediting the materials formulation and synthesis process. This can significantly reduce the time to arrive at the right material uses and avoid the trial and error method in the laboratory.

Materials informatics

Materials informatics combines AI and ML techniques to extract valuable information from vast datasets. By analysing data related to materials’ synthesis methods, properties, and performance, researchers can uncover hidden correlations and patterns. This knowledge helps in optimising material manufacturing processes, ensuring better performance and resource utilisation.

Process optimisation and quality control

In material manufacturing, the production process and product quality are of paramount importance. AI and ML technologies enable real-time monitoring and control of manufacturing processes, ensuring consistency and quality.

Predictive maintenance

Machine learning models can predict equipment failures and maintenance requirements, allowing manufacturers to schedule maintenance activities proactively. This minimises unplanned downtime, reduces production losses, and extends the lifespan of machinery.

Quality assurance

AI-powered image recognition and computer vision systems are employed to inspect and assess the quality of materials during the manufacturing process. These systems can detect defects, anomalies, and deviations from quality standards, enabling immediate corrective actions and reducing waste.

Supply chain and inventory management

Efficient supply chain and inventory management are critical in material manufacturing. AI and ML algorithms can optimise inventory levels, predict demand, and suggest procurement strategies. This reduces inventory holding costs and ensures that materials are readily available when needed, improving overall efficiency.

Environmental impact reduction

Material manufacturing is often associated with significant environmental impacts. AI and ML can help mitigate these effects by optimising processes, reducing energy consumption, and minimising waste. Sustainability-focused AI models are being developed to guide material selection and manufacturing decisions that align with environmental goals.

AI in warehouse operations

AI can automate various aspects of warehouse management, allowing manufacturers to monitor their stockrooms and enhance logistics using continuous data streams. By automating quality control and inventory processes, warehouse management costs can be reduced, productivity can be boosted, and the need for a large workforce can be minimised. This automation not only improves efficiency but also enables manufacturers to increase revenue and earnings.

Challenges and considerations

While the integration of AI and ML in material manufacturing offers numerous advantages, there are several challenges and considerations to address:

Data availability and quality

Access to high-quality data is crucial for AI and ML models. Ensuring data accuracy, completeness, and reliability is a challenge in many manufacturing settings.

Interdisciplinary collaboration

Material scientists, engineers, and data scientists must collaborate effectively to develop and deploy AI solutions successfully.

Ethical and regulatory concerns

Ethical considerations related to data privacy, bias in algorithms, and compliance with regulations must be addressed in AI applications.

Future prospects

The future of AI and ML in material manufacturing is promising. Continued advancements in AI algorithms, hardware, and data infrastructure will further enhance their capabilities. Researchers are exploring AI-driven generative design and autonomous manufacturing systems, which could revolutionise the industry’s landscape.

Some potential areas for future research and development include:

Autonomous factories

The development of fully autonomous material manufacturing facilities that utilise AI to make real-time decisions, optimise processes, and minimise human intervention.

Advanced materials discovery

Continued exploration of AI-driven generative design to discover materials with unprecedented properties and applications.

Sustainable manufacturing

Integrating AI and ML to minimise environmental impacts by optimising energy usage, waste reduction, and sustainable material selection.

Human-machine collaboration

Investigating ways to enhance human-machine collaboration in material manufacturing to leverage the strengths of both.

The integration of artificial intelligence and machine learning technologies in material manufacturing has ushered in a new era of innovation and efficiency. From materials design and synthesis to process optimisation and quality control, AI and ML are driving improvements across the entire manufacturing ecosystem. While challenges remain, the future prospects are bright, promising a more sustainable, efficient, and technologically advanced material manufacturing industry.

The author, Dr Mukesh Kumar Madhup, is associated with Amatech Innovation (OPC) Pvt Ltd, Ahmedabad