Building on our series, we journey from axiomatic designs to future-proof product design strategies. In a world of evolving preferences, crafting winning products that command loyalty and premium value hinges on quality, customer affection, and lasting engagement

In our previous articles, we have delved into the art of creating exceptional products. Yet, in the real world, satisfying customers often calls for more than just one offering. While launching with a single product can minimise initial risk and help us grasp customer expectations, it is essential to evolve. Soon enough, the demand for variety becomes evident as we strive to maintain customer happiness.

But here’s the catch: Shaping these fresh variants from scratch comes at a hefty price. Enter the realm of smart design. A skilled designer anticipates future needs and strategically lays the groundwork during the initial creation phase.

So, how do we approach this systematic product design that sets the stage for seamless expansion? Join us as we uncover the strategies to develop products that not only thrive in the present but also pave the way for an exciting future.

Over time, customer preferences and expectations will shift, leading to changes in how they perceive different features. The Kano Model is a tool used to understand customer preferences and prioritise features or attributes of a product or service. This shift in the Kano Model can be understood through three main phases: ‘emerging,’ ‘expected,’ and ‘basic.’

In the ‘emerging’ phase, new and innovative features that customers didn’t expect are introduced. These features can delight customers and lead to higher satisfaction because they go beyond what customers thought they would receive. However, as time goes on and these features become more common, they transition to the ‘expected’ phase.

In the ‘expected’ phase, features that were once innovative are now seen as basic requirements. Customers have come to expect them, and their absence can lead to dissatisfaction. These features are no longer a source of delight; instead, they are essential just to meet customer expectations.

Finally, in the ‘basic’ phase, even features that were once considered expected might become so commonplace that customers no longer pay much attention to them. At this point, these features are taken for granted, and their presence doesn’t significantly impact customer satisfaction.

To stay competitive and maintain customer satisfaction, businesses need to continually innovate and introduce new features that can move from the ‘emerging’ phase to the ‘expected’ phase. This cycle of shifting preferences highlights the importance of understanding customer needs and staying attuned to changing market dynamics.

There is a tool called the Generational Variety Index (GVI) that helps us to find and predict the parts that are likely to change in our future products. It’s like a compass that guides engineers, designers, and innovators as they navigate the complex journey of creating new products.

The GVI is a dynamic tool. As the project progresses and you gather more information, your understanding of the market, technology, and customer needs may evolve. The GVI adapts accordingly, helping you make informed decisions about when and how to adjust your product’s direction. Let us apply the concept of GVI to find out how our charge controller design will be impacted in the future.

GVI steps

Change estimation

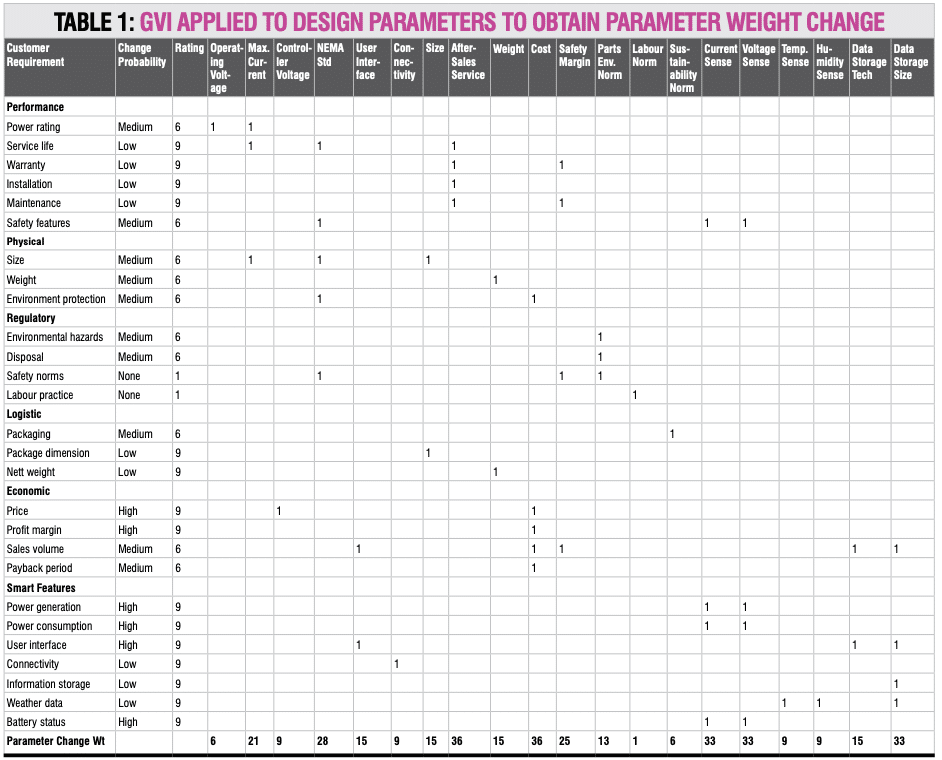

The calculation of the GVI relies on insights from our earlier discussion about QFD analysis in the previous articles of our series. In the QFD assessment, we compiled a list of customer expectations. When computing the GVI, we predict the potential change in these expectations over time. This prediction employs a four-point scale to indicate:

• High (Rating 9)

• Medium (Rating 6)

• Low (Rating 3)

• No change expected (Rating 1)

Once estimated, these values are applied to the design parameters, and their cumulative values create the parameter change weight (PCW) shown in Table 1.

GVI estimation

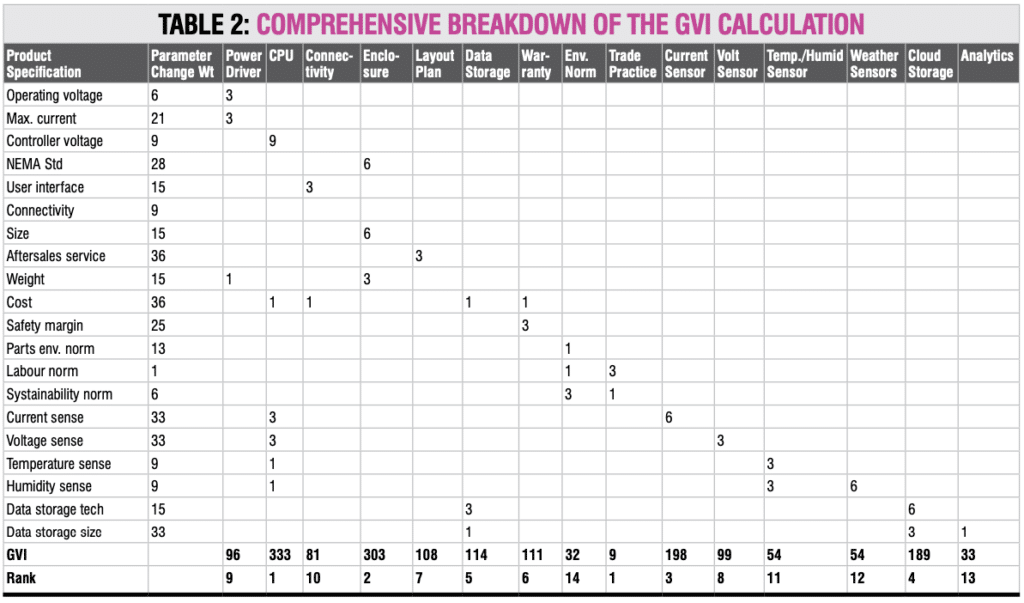

The parameter change weight (PCW) offers a glimpse into which design parameters might evolve in the future. Our next stride involves the second aspect of QFD, the design parameter house. In this stage, we integrate the PCW values and gauge the ease or difficulty of altering the design components associated with each parameter. Here, the same four-point scale as the PCW estimation is employed:

- High (Rating 9) – Demands significant product redesign

- Medium (Rating 6) – Requires partial component redesign

- Low (Rating 3) – Necessitates simple component alterations

- None (Rating 1) – Entails minimal design changes

Following the evaluation of change difficulty, we multiply the difficulty weight by the PCW and consolidate the values column-wise. For a comprehensive breakdown of the GVI calculation, see Table 2. Notably, the CPU and enclosure emerge as pivotal components with a substantial likelihood of future impact and a considerable challenge in terms of redesign. Hence, these are the segments where accommodating future changes is paramount.

Coupling index

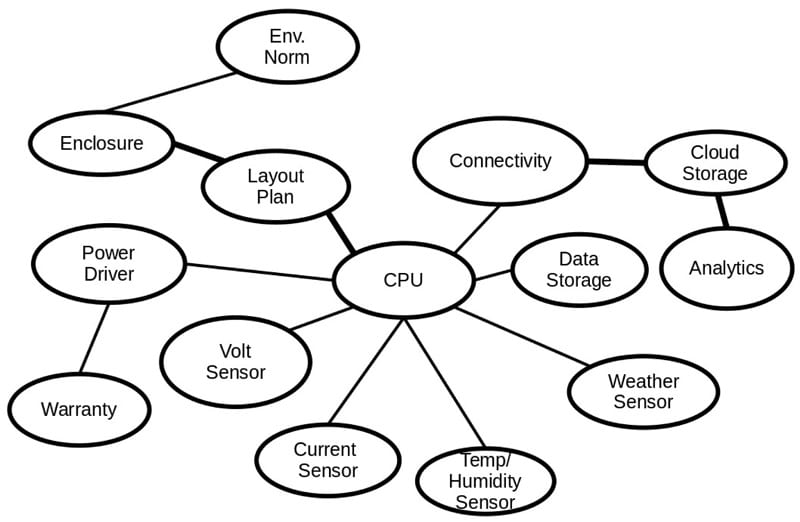

In practical scenarios, tweaking a design component often necessitates alterations in its interactions with other components—termed coupling. While GVI provides valuable insights, it does not convey coupling information. To discern coupling levels, we delve into part interrelationships, a process requiring distinct tools. Complex systems benefit from mathematical approaches and algorithms. For relatively straightforward products, a relationship graph suffices.

Begin with the highest GVI component and identify its interconnected components. Robust interfaces, entailing major changes with main component alterations, are depicted with thick lines. Conversely, weak interfaces, demanding minimal adjustments, are represented by thin lines.

Modules

Our design predominantly hinges on modular components, minimising complex interconnections. Designs replete with intricate interlinked components benefit from consolidation into distinct modules.

In our setup, we will form a separate module for power driver relays, voltage, and current sensors. This modularisation streamlines power rating changes for the charge controller. The weather sensor, an optional item positioned away from the controller, follows a similar approach.

A distinct module encompasses cloud storage and advanced analytics for the charge controller, facilitating upgrades sans hardware modifications.

Furthermore, the CPU’s limited memory capacity prompts the prudent use of an SD data card for storing large HTML and graphic files. Accompanying software adjustments are warranted.

Product variants

In our analysis, it is evident that our product comes in at least six distinct configurations:

1. Basic charge controller with battery monitoring

2. Charge controller with simple weather monitoring

3. Charge controller and weather station combo

4, 5, and 6. All three options with cloud-based analytics

However, the idea of producing and managing all six variants raises a few challenges. For one, it could quickly turn into a logistical headache. Distributors would need to handle a larger inventory, and this might lead to situations where customers cannot find the exact product they desire.

Moreover, taking on such a plan might also impact our profits negatively. While offering a wide array of options is appealing, the costs and complexity involved could eat into our bottom line.

Striking the right balance between variety and manageability is essential. We want to avoid overwhelming our distribution network and leaving customers unsatisfied due to product unavailability. At the same time, we must consider our financial health in this venture.

Ultimately, the decision we make needs to factor in the convenience of our customers, the efficiency of our operations, and the sustainability of our profits. It is about finding the sweet spot that benefits all stakeholders involved.

Creating product family

Customers’ expectations for our products can vary widely. While there is a plethora of product choices available, it is essential that we strategically balance options and expenses.

Modular design plays a crucial role in our flexibility, allowing us to effortlessly integrate or remove features. For instance, consider our cloud-based analytics feature—we can seamlessly offer it alongside the original hardware without any changes. Additionally, we could introduce an add-on weather station, albeit some adjustments to our base design would be necessary.

Speaking of variations, the distinction between our basic model and the simplified temperature and humidity monitoring version lies primarily in the sensors used. The big question is whether we should craft a combined design for both the weather station variant and the basic model or opt for distinct designs for each.

To untangle these decisions, our focus shifts to calculating the overall expenses for each option based on expected sales volume. In this scenario, our market research team projects sales of 2,000 units of the base model, 1,500 units of the model with basic weather monitoring, and 500 units of the model with a separate weather station per month.

Incorporating communication with the weather station requires an RS232-RS485 converter chip, priced at ₹40. The primary difference between the base model and the basic weather station comes from the DHT-11 sensor, valued at ₹70. If we integrate these components into our base circuit, we’ll be confined to a single product configuration.

However, our logistical expert emphasises that maintaining separate stocks for each variant would demand about a 15-day supply for each type. Contrarily, a single product type necessitates only 1,000 units in inventory. Our estimated product cost stands at ₹3,500.

In a nutshell, combining all three variants into one assembled product incurs an additional cost of ₹280,000 per month—calculated as ₹40×(2,000+1,500)+`70×2,000. Opting for separate inventories entails a cost of ₹3,500,000, alongside an additional inventory carrying expense of ₹700,000 due to a 20% capital cost.

The carrying cost of inventory surpasses the component costs. Hence, a pragmatic approach would involve maintaining a singular product configuration while offering the remote weather station and cloud analytics as optional items, possibly on a subscription basis. This approach ensures a harmonious balance between customer choices and efficient resource management.

Previously, we have delved into the art of creating products, from the initial spark of an idea to a thriving product family. These concepts are versatile, and suitable for crafting physical goods, software, or services.

The key to a triumphant product lies in its quality, the affection it garners, and its ability to engage customers consistently, turning into a habit. Products of this calibre and their variations tend to cultivate customer loyalty, standing the test of time. Often, customers are willing to invest a premium for the privilege of owning such cherished products.

In our upcoming and final article, we will explore the last piece of the puzzle: Packaging and the crucial realm of after-sales service.

Soumyanath Chatterjee is former TVS Motors Chair Professor at Industrial and Systems Engineering Department, IIT Kharagpur. His expertise is in Product Development and Supply Chain Management