There have been several acquisitions in the microprocessor and microcontroller industry recently. Let us take a look at the state of affairs and how the industry is facing. Designing, manufacturing, and selling a new processor is not easy, but open source seems to help.

We have x86 processors made by Intel and AMD, and ARM processors by various IC vendors who make them in multiple flavours. These are the only high-end microprocessors at present. Whereas 8- and 16-bit microcontrollers are available from multiple vendors like Microchip, Texas Instruments, NXP, ST, and Infineon, to name a few.

But during the last two years, the high-end microprocessors—especially with x86 architecture—have started facing competition from ARM based controllers in power consumption, speed, and multiple cores. This has put huge pressure on the legacy microprocessors, which are the mainstay for PCs and servers.

However, Apple has broken their monopoly in PCs by switching over to ARM based controllers, which deliver far superior performance, putting pressure on the x86 processor family. But ARM is not a semiconductor as an integrated circuit but rather an IP (intellectual property) core, which the licensees can customise to create devices as per their needs.

This has led to proliferation of ARM based products across the board and major beneficiaries are mobile phones and embedded systems (not the PCs and servers!). Things had been going fine but suddenly the company ARM was bought over by the graphics processing units (GPUs) producer NVIDIA, leading to a major consternation. This has left every semiconductor company wondering what is going on.

The current situation

Since fast few years, x86 based processors are being challenged by the ARM based controllers in critical aspects like power, speed, size, and number of cores, with ARM based processors capturing the complete mobile market. Also, software for the ARM processors was never an issue as the volume of mobiles was much higher than of the PCs shipped.

Adding to this was ARM’s business model of just licensing IP and leaving the realisation of devices to the vendors, which gave a lot of freedom to the mobile vendors. In addition, next-generation fabless vendors, who designed the best-performing processors and got them manufactured through outsourced semiconductor foundries, added more traction to the ARM based systems.

One interesting event that happened on sideline was the acquisition of mainline programmable logic device vendors, mainly FPGA (field programmable gate array) vendors like Xilinx and Altera, by mainline processor vendors. Intel bought Altera and AMD bought Xilinx. These acquisitions changed the game further.

These vendors acquired the programmable logic vendors to bolster their datacentre products as the datacentre interconnects were reaching 100Gps speed and there was need for hardware based solutions, which typically only FPGAs can offer! When things were coasting along, NVIDIA announced the takeover of ARM. (There are some issues which the Competition Commission is looking at, but as of now ARM is owned by NVIDIA.)

It is not that low-end 8- and 16-bit microcontrollers business was hale and healthy. There was a huge churn in that market too, but the controllers made by different companies have not been dropped (so far!). Microprocessors like 68000 family and 8086 family have become obsolete. In the 8-bit controller side the situation is pretty bad! Processors like 65C02 from Rockwell, 6800 and 6809 from Motorola, 8085 processor and 8051 microcontroller from Intel have all become obsolete.

Interestingly, 65C02 is still being offered by some vendors as a custom ASIC (application specific integrated chip). 8051 does have incarnations from vendors like Atmel, Silicon Labs, and Nuvoton, who have processors supporting 8051 instructions but through their own custom IC architecture. Today 8- and 16-bit controllers are pretty much dominated by TI, Microchip, and NXP, who have significant market share. But this is not an exhaustive list. The idea is to set the context on what it takes to develop a microcontroller in the current situation.

Interestingly, 65C02 is still being offered by some vendors as a custom ASIC (application specific integrated chip). 8051 does have incarnations from vendors like Atmel, Silicon Labs, and Nuvoton, who have processors supporting 8051 instructions but through their own custom IC architecture. Today 8- and 16-bit controllers are pretty much dominated by TI, Microchip, and NXP, who have significant market share. But this is not an exhaustive list. The idea is to set the context on what it takes to develop a microcontroller in the current situation.

With ARM being acquired by NVIDIA, one big challenge facing the ARM processor vendors is that they do not have access to a vendor-neutral processor (where the core vendor is not associated to any major vendor but is independent), making the situation dicey. How NVIDIA will handle the ARM core licensing going forward is not known. So far the vendors are safe producing their existing products, but future will depend on what NVIDIA decides.

This has forced companies and countries to start worrying about the impact of these acquisitions and consolidations. With electronics taking over most of the day-to-day life, the equipment are getting critically impacted. This is especially true in the case of defense equipment. Independence of the technology, and even freedom to develop, will be under pressure due to access to advanced processor architecture and even the IP core, going forward!

Strategic issues

One of the biggest issues that everyone is facing is, how to develop products and solutions without any restrictions. Under this circumstance the only way to find a solution is to look at open source solutions. We in India have a successful track record of using Linux. With Linux taking over the internet servers and other critical applications (have to admit Linux couldn’t replicate the success in the desktop market, barring the developer communities) we have demonstrated that open source technologies can be successfully adopted.

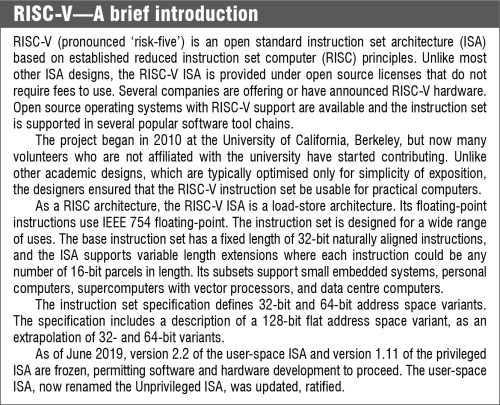

The logical thinking is to replicate the same model for processors. This has become feasible with the availability of RISC-V, an open source architecture which basically defines the instruction set architecture, leaving the implementation to the designers. This has led to multiple versions of RISC-V implementations available for designers to develop.

One advantage of the RISC V architecture is that it offers device options that can compete with 8/16-bit processors and high-end 32- and 64-bit variations with single and multiple cores. This offers multiple options with. a single open architecture. One question as laymen we get is, why a processor has become the critical issue now?

Three critical aspects are important for any country to maintain independence and progress on the technology front. These are:

- Independence to decide and develop technologies that are a must for the country’s progress.

- Availability of parts (no supply chain bottlenecks) freely. We should avoid the current situation of companies waiting for ICs and other parts.

- With the world becoming connected and proliferation of connected devices, one of the worrisome aspects is the security. We are not talking about the phishing and hacking but the connected devices being hijacked and spoofed to impact the day-to-day life of the citizens. One example would be, as part of smart city project there will be sensors which monitor the environment—especially pollution. Imagine if a hacker replaces the installed (good/genuine) devices with faulty devices so that even when the environment is polluted the devices report everything is fine. You can understand the impact on the society as a result.

This essentially means that the communication must be encrypted and, above all, the devices have to be validated and approved by the installer. While this looks easy, implementation is a challenge which needs a solution that mandates the devices to be uniquely identified (yes, each IC should have a unique certified id!). In addition, these devices should be validated before they are allowed into service, and need to be periodically checked for presence of a valid device.

We can see the evolving situation demands that the processors cannot be a plain vanilla type but a device whose history can be traced and identified. This requirement is going to be implemented as we go forward. USA NIST has released NISTR 8228 (Considerations for Managing Internet of Things (IoT) Cybersecurity and Privacy Risks) standard for this purpose.

Incidentally, in the Indian context, UIDAI has already updated its next-generation fingerprint sensor’s compliance to secure processors and to be independently verified and validated by STQC before the sensors are put in the field. This ensures absolute safety of the customer’s data. The same is true for military equipment too.

The situation in India

Real purpose of this article is to educate readers on what it takes to design a processor in India and persuade companies and other organisations to use it. Let us first see the lifecycle of a semiconductor design, which would help us understand where we stand today.

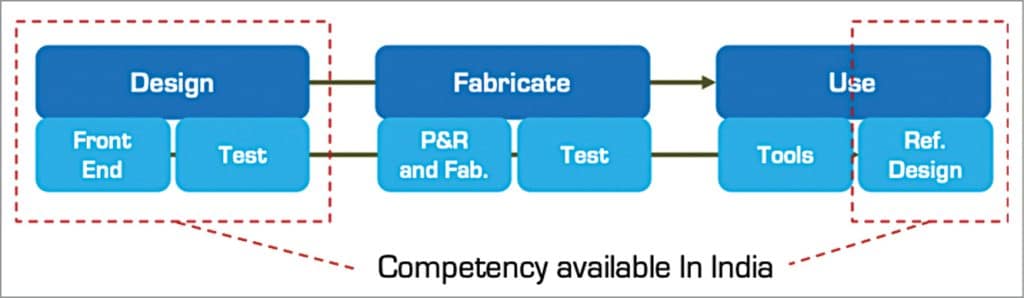

Fig. 1 shows very simple flow chart of an IC design for easy understanding. The lifecycle consists of three major blocks:

1. Design phase, which has two steps before the design is ready for the IC’s fabrication. This is purely an engineering effort that requires experienced designers who can develop an IC using languages like Verilog or VHDL. The process of coding an IC using one of these languages is typically called front-end design.

Typically, a processor design involves the coding of the main core and integration of libraries for different peripherals needed in the processor/controller. In the next step, the coded IC has to be tested completely using test benches. These are Verilog/VHDL codes written exclusively for testing (something very close to simulation of the boards for their working before committing to the PCB).

2. The tested code is converted into the GDSII format, which is used by the IC fabricators—also known as foundries—to manufacture the ICs. Fabrication process has four steps before it is converted to individual ICs:

(i) First process in fabrication is the Place & Route (P&R) (also known as back-end), which is the equivalent process of PCB routing. P&R process is very specific to each foundry as it is dependent on semiconductor process used by the foundry.

(ii) P&R output is converted to masks and the ICs are fabricated in a large 20.3cm or 30.5cm (8-inch or 12-inch) wafer. A wafer will have multiple ICs known as dies.

(iii) Foundries test each of the ICs (dies) and mark the good and the bad ones in the wafers.

(iv) Typically, foundries deliver the tested wafers to the OSAT (outsourced semiconductor assembly & testing) vendors. These OSAT vendors cut the individual ICs, package them based on the chip vendors’ design, test and mark them and deliver. OSAT is typically an intensive manual process, and most semiconductor foundries outsource this to companies who specialise in this service. Malaysia, Vietnam, and Indonesia are the major OSAT locations.

3. At this stage the IC is ready and can be used for designs. Life would be easy if the IC happens to be a simple device like an op-amp. (This is not true as you still need a datasheet with specifications to use the device). But if the IC happens to be a microprocessor, the life is different. Any microprocessor that is introduced in the market needs three critical items as a must to succeed:

(i) Foremost are the software development tools consisting of assemblers, compilers, integrated development environment (IDE) to help the software developers to work with the processor. Tools have to be efficient in terms of compilation efficiency, optimal (size) compiled code, and libraries for the peripherals in the devices.

(ii) Second part of the tools is the operating system support. Typically, a standard OS like Linux and real-time operating systems like FreeRTOS should be ported on to the processor and delivered as ready-to-use component for the designers to focus only on the application development. Along with this board support package (BSP), a piece of firmware which allows the OS to work without worrying about the underlying processor variation, should be ported.

(iii) With focus on reduced time-to-market, another support item that is expected by the designers is the reference designs that demonstrate the hardware features of the processor. These reference designs have to be a total package covering the schematics files, PCB CAD files, Gerber files, and the firmware code that runs on the reference board. This helps the designers understand the design and develop their designs. Many times, designers use this for their proof-of-concept prototypes.

Now we can see what processes can be done in India to develop a processor from scratch. Considering the current situation in India, Fig. 2 shows what can be done in India and what can’t be! The ones under the red boxes are skills that are available in India. For the rest we need infrastructure.

We can see that while we have good competency in designing, we have very less in the subsequent stages—barring some experience in the reference design. Having understood the current status let us see why we need an Indian processor.

Need for Indian processor

This was the main reason for this article. Three key elements that drive the need for an Indian processor are:

1. Primary reason is the security. With the proliferation of connected devices ensuring end-to-end security is the most critical issue. This calls for secure communication (encryption) and authorised devices. While the encryption is easy to implement, designing authorised/certified devices calls for certifying every device and the authentication mechanism must be located inside India. This ecosystem is extensive and needs to be installed before the production of ICs starts. Today, even though authorised/certified devices (also called trusted devices) are available from global vendors, the device data is located outside India, which is a security risk.

2. Avoiding supply chain risks. As we have seen, severe shortage of semiconductor devices due to Covid, especially of processors, is leading to lower sales, even though products are in demand. One question people may ask is, if we don’t have the foundries, how it will improve the supply chain? The answer is in the business model. Foundries like TSMC work based on committed contracts, and if you have signed up for a fixed number of devices and you have honoured the commitments previously, they do supply as per the agreement.

3. Third is having own microprocessor helps to train the designers in design and also ensures the knowledge is captured and used. This design knowledge is very critical for the defence and smart city applications, which are critical and need to be secured as they impact the society.

In addition, an Indian processor would also bring the cost down and reduce the development time as the processor proliferates. Above all, it would save the country from obsolescence of the processors in a short time, leading to support and new design effort issues. Having Indian processor allows the product to be obsoleted based on a planned strategy instead of panic mode reaction. (The panic is despite the IC vendors giving proper obsolescence notice as well as last time buy options, which product companies tend to ignore!)

How India can have own processor

How India can have own processor

With the semiconductor supply chain crisis hitting every domain, the issue of supply chain security has come to fore and shown how critical it is to secure a supply chain. Having learnt, it is high time that India has its own microprocessor with a secured supply chain. With most processors being supplied by global vendors, India must have own processor that can use the RISC-V architecture as the best option.

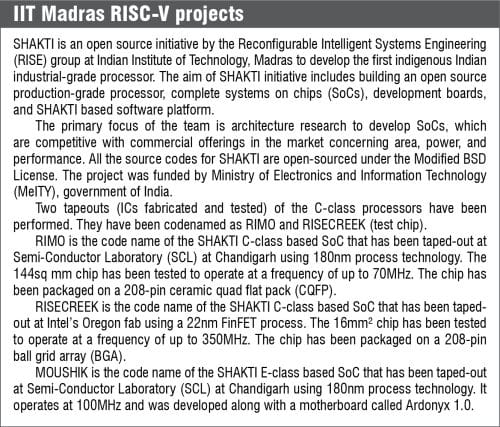

In this regard, IIT Madras has been a pioneer and has developed two processors, Risecreek and Moushik. IITM’s team has been successful in the conversion of the RISC-V architecture into ASICs as well as FPGA based processors. Since RISC-V defines the instruction architecture, speed and other aspects can be decided by the design teams offering flexibility.

One advantage is that the architecture is not technology specific, and designers can target different fabrication technologies to get different speeds. One of the biggest advantages of the IITM’s design is the availability of operating systems for these processors. IITM team has ported both Linux and Free RTOS on to these processors. They have used open source tools for the software development, making the ecosystem truly open source.

Yet, one challenge that designers face will be that the tools being open source will not have the integration of the commercial IDE provided by the regular vendors. The tools are a little difficult to use. But this will change once the adoption of RISC-V picks up. Newer versions will address the security and other aspects needed for trusted devices.

Key to success in having an Indian processor lies in how quickly commercial device developers adopt the RISC-V architecture and develop different flavours of the processor. While it is easier said than done, need for the Indian processor will only increase as the time passes. Some of the challenges that need to be overcome are:

- A processor development needs a huge investment to get a working processor taped out commercially (through outsourced foundry services). Waiting for a foundry to come up is not a viable option as foundries with advanced technologies are expensive.

- However, India should focus on setting up OSAT (outsourced semiconductor assembly & test) facilities which convert the processed wafers with ICs into individual devices. OSAT facilities are less expensive and more manual work oriented, so they can be a good option as a business model too. Also OSAT facilities are device-independent and very close to the business model of EMS (electronic manufacturing services) vendors.

- Creation of software tools, libraries, domain-specific applications (like avionics, automotive, and medical, which need reliable software modules) and reference hardware and circuits for the designers to try their ideas before they commit to the product design.

- Training designers, especially students, in the RISC-V architecture and its ecosystem so that when they start designing, they have the knowledge needed for developing products. Today, students still study 8085 and 8086 processors, which are obsolete and not in production. At the same time teaching them RISC-V without the devices being available is a wasted effort.

- Startups who work on RISC-V based system to kick start the next wave of products.

From the support point of view, government should support the effort by incentivising the designs based on RISC-V and mandating the use of these processors in critical government departments like defense, citizen’s benefit programmes like Aadhaar, and backing devices.

To conclude, with so much of hype around an Indian processor, we need to remember that for a processor to become successful it needs support at multiple levels. Harping on a foundry is not going to solve the problem and creating an ecosystem is a must.

S.A. Srinivasa Moorthy is Director Engineering Design, D4X Technologies Pvt Ltd